Method for improving smoking stability and heat utilization rate of heated cigarette

A stable and efficient technology, applied in application, tobacco, cigar manufacturing, etc., can solve problems such as inability to effectively change the release fluctuation of the smoking medium, carbonization and crushing of cigarette paper, affecting the smoking experience, etc., and achieve machine adaptability. Good, improved heat utilization, good suction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

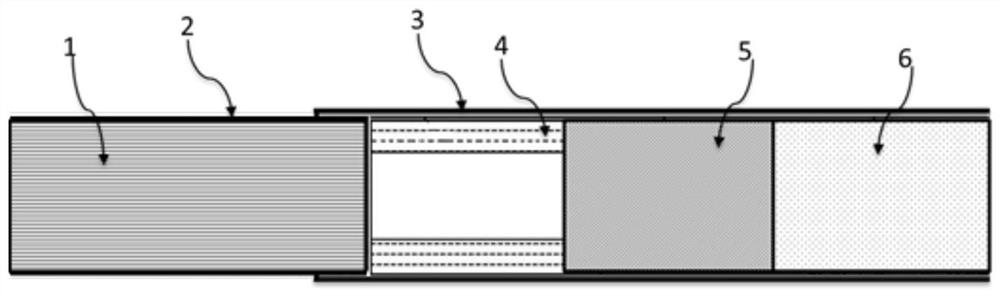

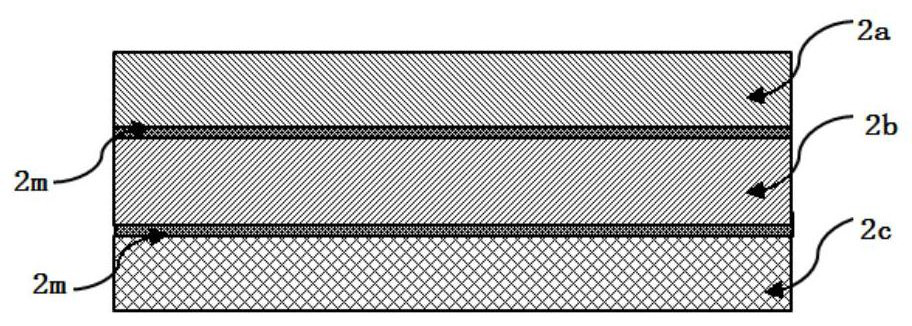

[0025] A method for improving the smoking stability of heated cigarettes. The cigarette is prepared by the following operations: the cigarette includes a smoking medium section, and the smoking medium section is prepared by wrapping a smoking medium rod 1 with composite cigarette paper 2, The preparation method of the composite cigarette paper 2 is as follows: it is formed by bonding the first cigarette paper layer 2a, the graphite paper layer 2b and the coating layer 2c through the adhesive layer 2m, and the coating layer 2c and the hair The smoke medium rods 1 are in contact with each other.

[0026] The thickness of the graphite paper layer 2b is 55 μm.

[0027] The second cigarette paper layer used in the coating layer 2c is cigarette paper with a grammage of 40g / ㎡ and an air permeability of 1000CU, and the surface of the coating layer 2c is coated with additives, and the additives include a smoking agent 30wt%, essence 20wt%, gel 50wt%. The purpose of the gel is only to...

Embodiment 2

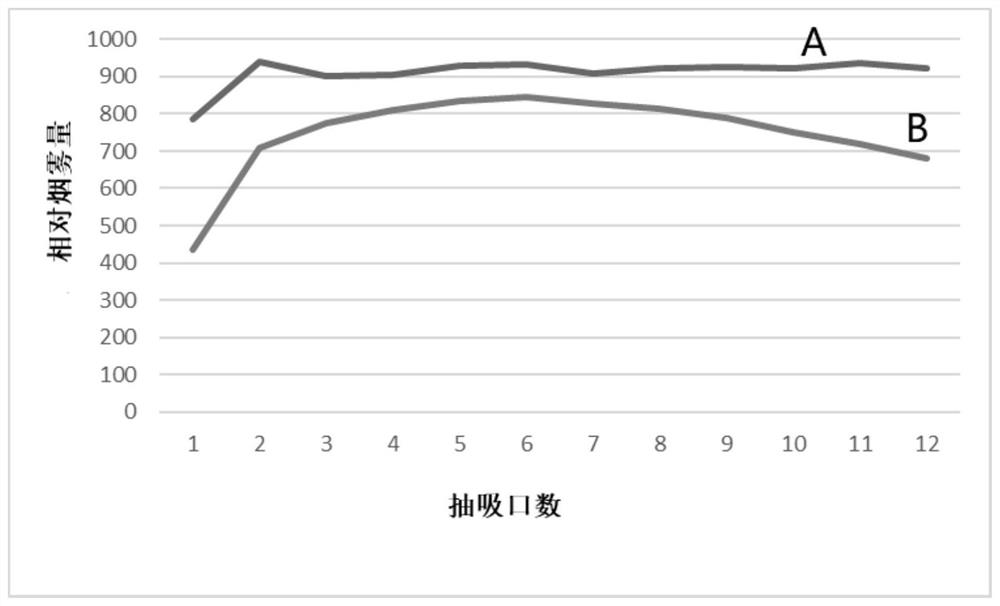

[0030] The same smoking medium was used to make heated cigarette B with the same structure, and the only difference from heated cigarette A was that the composite cigarette paper 2 of Example 1 was replaced with ordinary cigarette paper. Smoking tests were carried out on heated cigarettes A and B, and the results of the smoke volume during the smoking process of the two cigarettes were as follows: image 3 shown.

[0031] image 3 It shows that when the number of puffs is 7-12, the relative smoke volume of heated cigarette A can still maintain a high level, while the relative smoke volume of heated cigarette B decreases obviously. Therefore, compared with ordinary cigarettes, the cigarette prepared by the method of the present invention has more uniform release of substances required in the smoking process, better suction stability, and no obvious reduction in the amount of smoke that can be sucked up to 12 puffs.

Embodiment 3

[0033] The heated cigarettes A and B of Example 2 were smoke tested, and their nicotine release was tested as shown in Table 1. From the table, it can be seen that the cigarette paper using composite cigarette paper 2 in Example 1 can make the tobacco core base material smoke An increase of about 31.0% in the amount of alkali release can increase the utilization rate of the base material of the tobacco core.

[0034] Table 1 Effect of different cigarette papers on nicotine release

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com