Preparation method of leaf bundle type cigar core

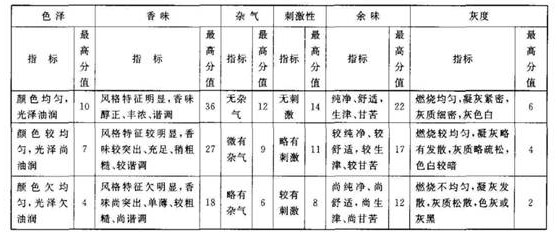

A technology of cigars and tobacco leaves, which is applied in the field of preparation of leaf-bundle cigar fillers. It can solve the problems of reduced fermentation uniformity, high bitterness of finished cigars, and incomplete fermentation, and achieves shortened fermentation time, less impurity gas, and high quality. and color uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a leaf bundle type cigar filler, comprising the following steps:

[0030] (1) According to the production plan and the formula of the product leaf group, prepare the filler tobacco leaves for feeding, put the accumulated tobacco leaves in a hot steam environment, and ferment for 20 hours for the first fermentation. The fermentation temperature is 55°C and the relative humidity is 65°C. %, the method of humidifying the tobacco leaves in advance with hot steam and stacking loose leaves can improve the permeability of the cells formed by the tobacco leaves, shorten the fermentation time, make the quality and color of the thicker tobacco leaves uniform, and improve the aroma and aroma quality of the tobacco leaves improve;

[0031] (2) Soak the tobacco leaves treated in step (1) in the fermentation liquid, then dry them, and put them into the fermentation room for the second fermentation. The second fermentation time is 60 hours, and the fermentation ...

Embodiment 2

[0039] A method for preparing a leaf bundle type cigar filler, comprising the following steps:

[0040] (1) According to the production plan and the formula of the product leaf group, prepare filler tobacco leaves for feeding, place the accumulated tobacco leaves in a hot steam environment, and ferment for 10 hours for the first fermentation. The fermentation temperature is 50°C and the relative humidity is 50°C. %;

[0041] (2) Soak the tobacco leaves treated in step (1) in the fermentation liquid, then dry them, and put them into the fermentation room for the second fermentation. The second fermentation time is 50 hours, and the fermentation temperature is 61°C. The relative humidity is 70%. The fermented liquid comprises jujube juice, sugar, rice wine and red rice. The fermented liquid comprises 8 parts of jujube juice, 10 parts of sugar, 16 parts of rice wine, 7 parts of red rice, 83 parts of water;

[0042] (3) Spray the mixed starter on the tobacco leaves treated in st...

Embodiment 3

[0048] A method for preparing a leaf bundle type cigar filler, comprising the following steps:

[0049] (1) According to the production plan and the formula of the product leaf group, prepare filler tobacco leaves for feeding, place the accumulated tobacco leaves in a hot steam environment, and ferment for 15 hours for the first fermentation. The fermentation temperature is 53°C and the relative humidity is 60°C. %;

[0050] (2) Soak the tobacco leaves treated in step (1) in the fermentation liquid, then dry them, and put them into the fermentation room for the second fermentation. The second fermentation time is 55 hours, and the fermentation temperature is 63°C. The relative humidity is 72%. The fermented liquid comprises jujube juice, sugar, rice wine and red rice. The fermented liquid comprises 8.5 parts of jujube juice, 12 parts of sugar, 17 parts of rice wine, 8 parts of red rice, 70 parts of water;

[0051] (3) Spray the mixed starter on the tobacco leaves treated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com