Electrochemical devices and electronic devices

An electrochemical and battery technology, applied in the field of electrochemical devices and electronic devices, can solve the problems of reducing the energy density of electrochemical devices and affecting the performance of electrochemical devices, and achieve the effects of increasing thickness, weakening shrinkage, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

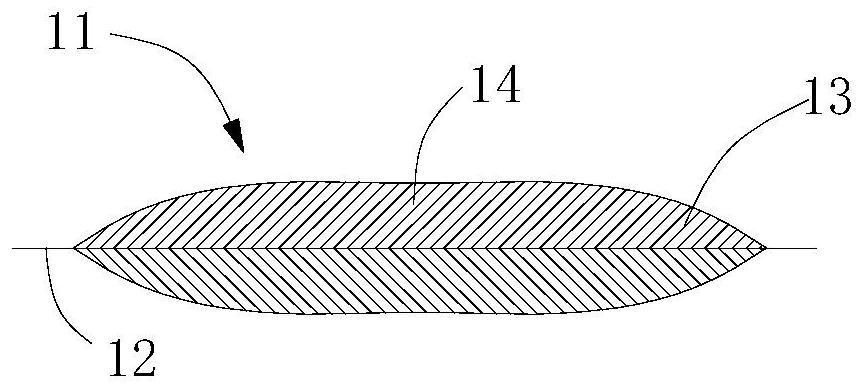

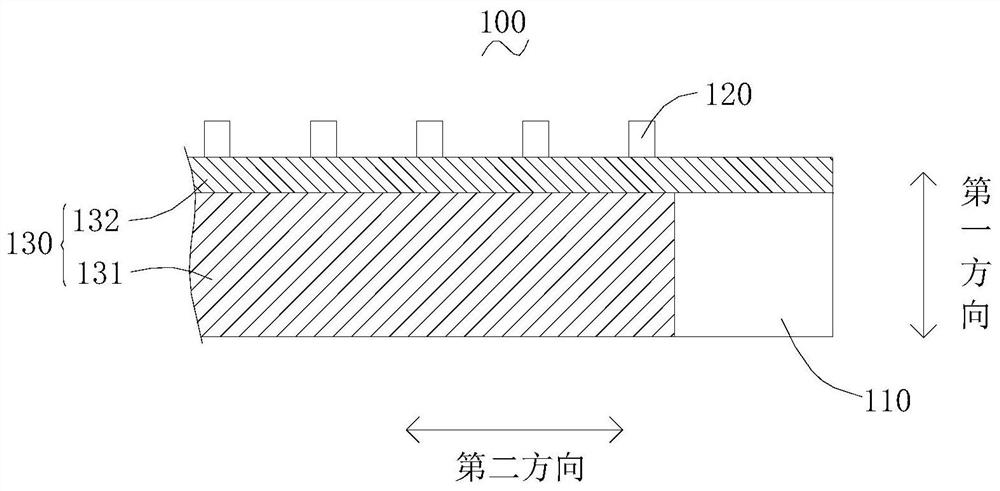

[0062] The first pole piece preparation process of embodiment 1 is as follows:

[0063] Mix the anode active material graphite, binder styrene-butadiene rubber, and thickener carboxymethyl cellulose in a mass ratio of 96:3:1, add water and stir to obtain a main coating with a solid content of 45% and a viscosity of 4500mPa.s Slurry; mix the anode active material graphite, binder styrene-butadiene rubber, and thickener carboxymethyl cellulose in a mass ratio of 98:1:1, add water and stir to obtain a slurry with a solid content of 48.4% and a viscosity of 7200mPa.s Edge coating slurry.

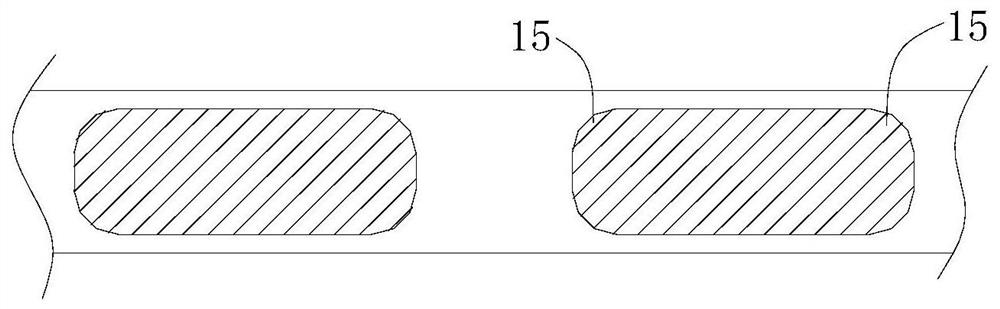

[0064] Inject the prepared main coating slurry and edge coating slurry into the corresponding feeding system respectively, and adjust the coating machine according to the parameters such as coating weight, coating width and coating length, in which the main coating is intermittently coated Cloth, continuous coating of the edge coating, the main coating slurry and the edge coating slurry are sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com