Rotary sealing device of graphite ring structure

A technology of rotating seals and graphite rings, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of dry friction, lack of sealing effect, and low service life, so as to achieve appropriate pressing force and increase friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

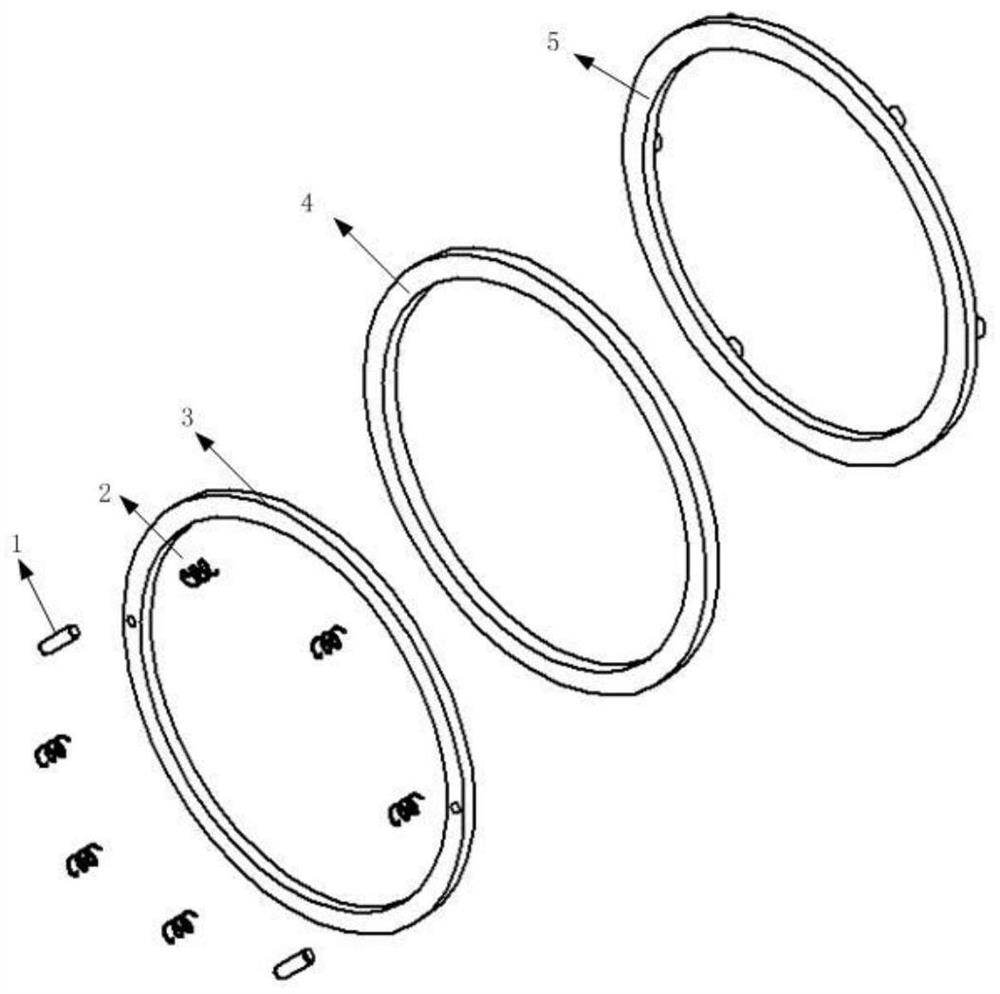

[0021] like figure 1 As shown, the present invention provides a rotary sealing device with a graphite ring structure, including a cylindrical pin 1, a spring 2, a support ring 3, a graphite ring 4 and an upper support ring 5, which mainly solves the problem of easy leakage of the rotary motion seal and excessive friction Difficult balance problem. The close fit of the graphite ring 4 and the supporting ring 5 can ensure no leakage of the seal, and meanwhile, the low friction coefficient of graphite ensures the low friction of the entire rotary seal.

[0022] The sealing method of the rotating moving part of the present invention is as follows: the rotating sealing device provided by the present invention is used to connect the external fixed part and the rotating moving part, and provides good sealing performance.

[0023] An annular groove is opened on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com