Double-well flexible roller oil pumping unit

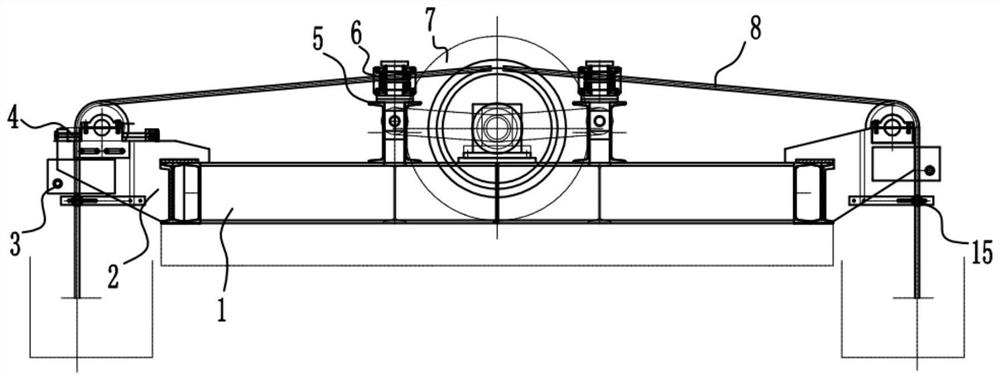

A pumping unit, a flexible technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of inconvenient maintenance and workover operations, high production cost, large amount of steel, etc., to achieve good durability Wear cushioning effect, compact shape, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

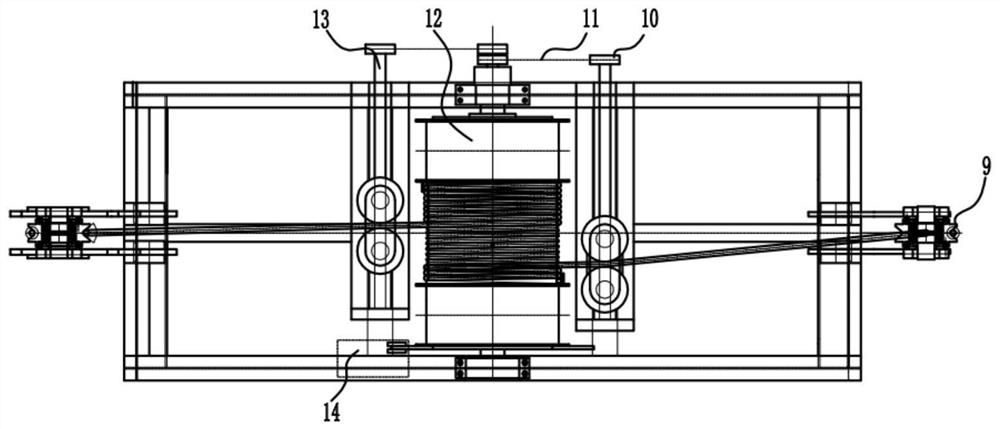

Method used

Image

Examples

no. 2 example

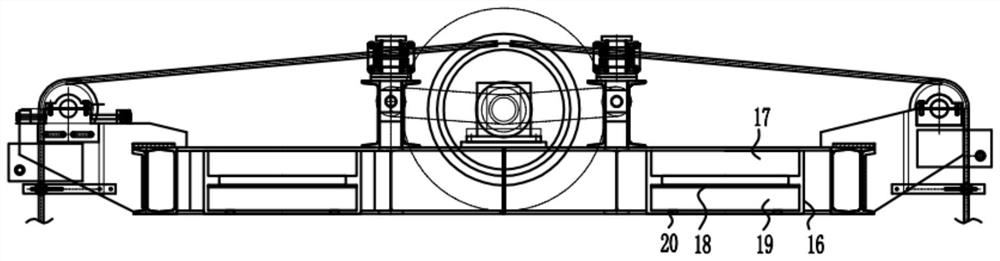

[0052] Please refer to image 3 , based on the double-well flexible drum pumping unit provided in the first embodiment of the present application, another double-well flexible drum pumping unit is proposed in the second embodiment of the present application. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0053] Specifically, the difference between the double-well flexible drum pumping unit provided in the second embodiment of the present application is that, for a double-well flexible drum pumping unit, the left and right sides of the large base 1 are provided with A cavity 16 is provided, and a telescopic cylinder 17 is fixedly mounted on the top of the inner cavity of the cavity 16 .

[0054] Telescopic cylinder 17 adopts program control, and telescopic cylinder 17 on both sides makes this device can adapt to the uneven ground te...

no. 3 example

[0063] Please refer to Figure 4 , Figure 5 , Image 6 with Figure 7 , based on the double-well flexible drum pumping unit provided in the first embodiment of the present application, the third embodiment of the present application proposes another double-well flexible drum pumping unit. The third embodiment is only a preferred mode of the first embodiment, and the implementation of the third embodiment will not affect the independent implementation of the first embodiment.

[0064] Specifically, the difference between the double-well flexible drum pumping unit provided in the third embodiment of the present application is that, for a double-well flexible drum pumping unit, the left and right sides of the large base 1 are provided with Lifting device 21, described lifting device 21 comprises installation bucket 211, and the inside of described installation bucket 211 is provided with lifting column 216, and the top of described lifting column 216 is fixedly installed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com