A kind of floor tile removal method and removal device based on microwave cracking cement stone technology

A technology of cement stone and floor tiles, applied in construction, building maintenance, building construction, etc., can solve problems such as damage, high labor intensity, noise disturbance, etc., and achieve the effect of tight connection and weakened integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

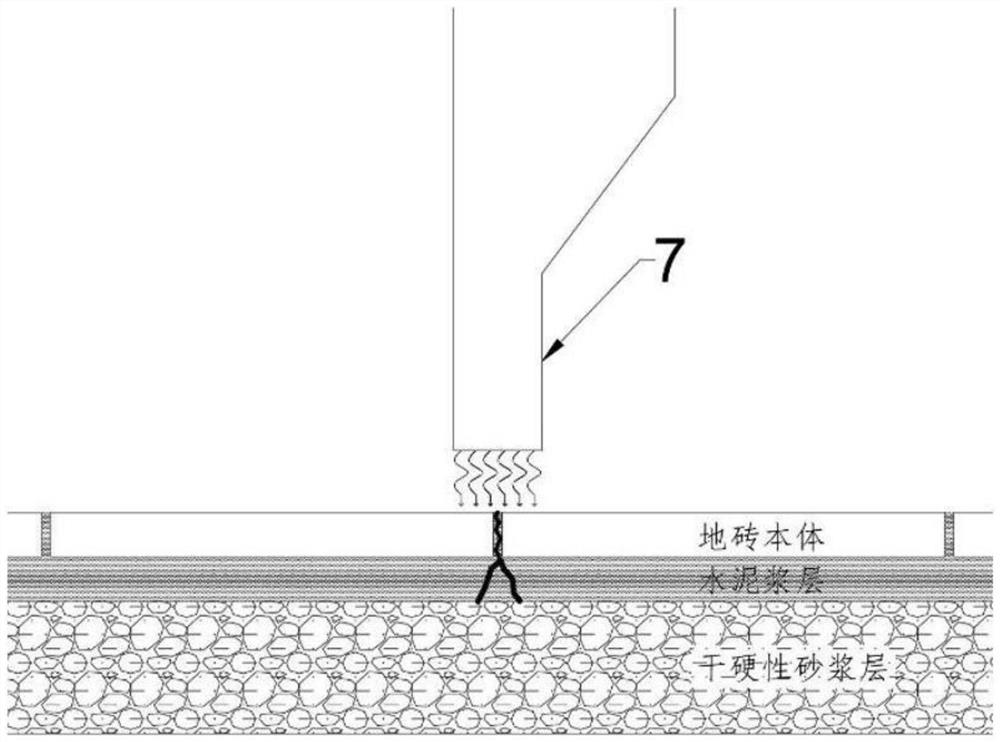

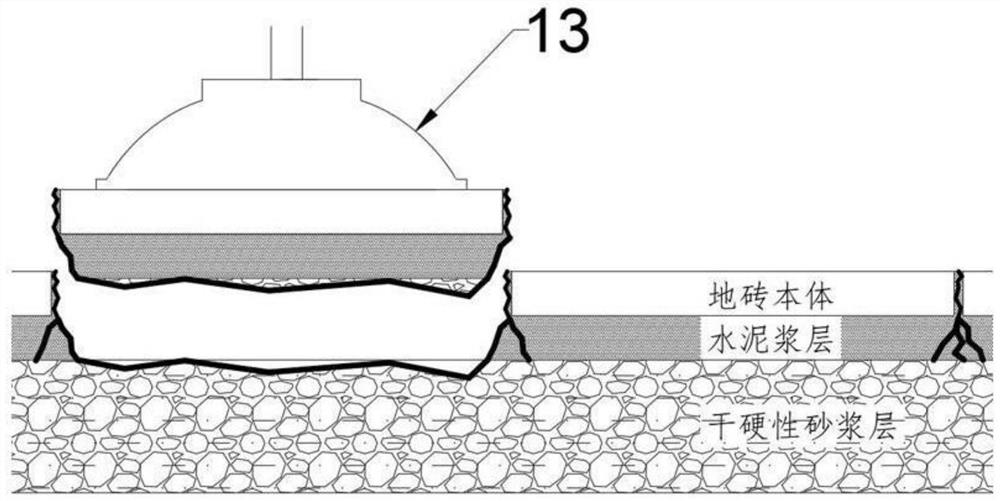

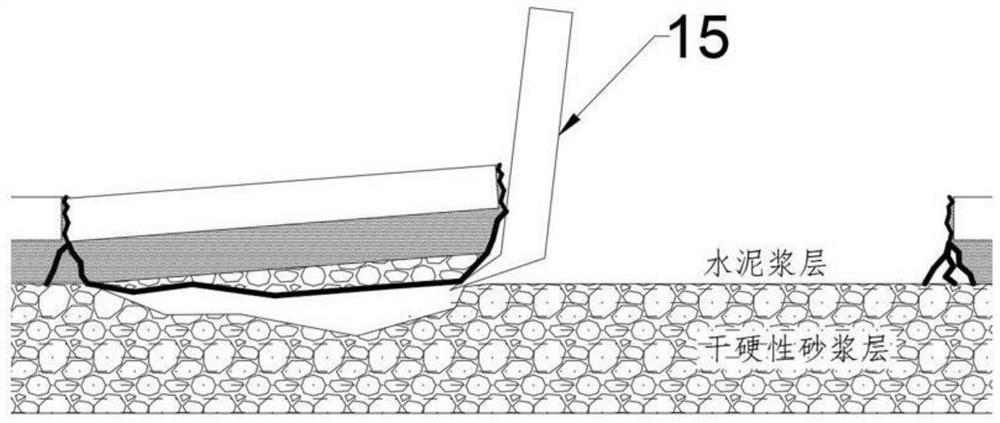

[0057] This embodiment provides a preferred embodiment, a method for removing floor tiles based on microwave cracking cement stone technology. The removal method involves a removal device, and the removal device includes a mobile device 12 , a shielding box 11 , a microwave power supply 1 , and a microwave system. , microwave focusing antenna 7, wherein:

[0058] The above-mentioned moving device 12 is placed on the ground to drive the above-mentioned dismantling device to move in the area to be dismantled; further, the above-mentioned moving device 12 includes a top plate and several universal wheels, and several universal wheels are installed at the bottom of the top plate. The number of wheels is four, which are respectively arranged at the four corners of the bottom of the top plate, and the moving device 12 can move in any direction through universal wheels.

[0059] The shielding box 11 is disposed above the mobile device 12 and is used to cover the microwave system insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com