Foamed aluminum sound insulation wall and construction method thereof

A sound insulation wall and foam aluminum technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of reducing indoor space utilization, wall bursting or burning, uneven wall unevenness, and improving sound insulation effect and wall thickness. Low, solid wall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

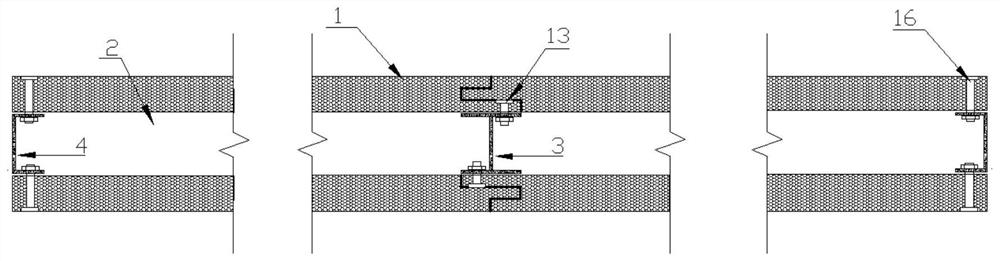

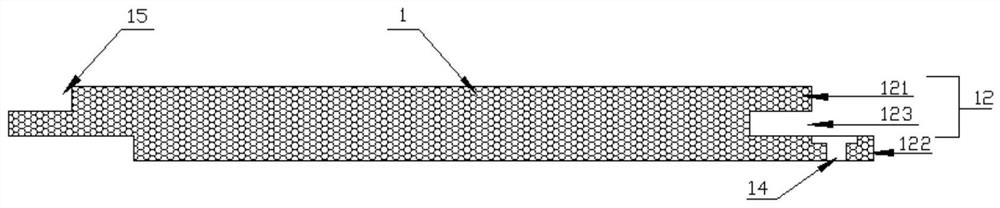

[0047] As can be seen from the accompanying drawings, a foamed aluminum sound insulation wall includes a wall with a hollow structure 2, a group of foamed aluminum plates 1 with a square main viewing surface are vertically provided on both sides of the wall, and there are intervals in the wall for fixing The H-shaped column 3 supporting the foamed aluminum plate 1, the two ends of the wall are provided with a C-shaped column 4 for fixing and supporting the foamed aluminum plate 1, and the bottom and top of the H-shaped column 3 and the C-shaped column 4 are horizontally provided with a mounting plate 5;

[0048] The bottom of the wall is provided with the joist 6 along the ground, the top of the wall is provided with the joist 7 along the top, the installation plate 5 at the bottom and the joist 6 along the ground, the installation plate 5 at the top and the joist 7 at the top are installed with the foundation through the bolt I8 The surface 22 is fixedly connected; both the gr...

Embodiment 2

[0057] It can be seen from the accompanying drawings that the difference in structure between the sound insulation wall of this embodiment and that of Embodiment 1 is that a metal partition 17 is arranged inside the hollow structure 2 of the wall, and the installation direction of the metal partition 17 is parallel to the aluminum foam board 1 , the metal partition 17 is fixedly connected to the rib plate of the H-shaped column 3 through the corner code 18 and the corner code bolt 19; The square tube 20 of the aluminum plate 1, the width of the square tube 20 matches the distance between the foamed aluminum plate 1 and the metal partition 17, the square tube 20 and the keel 6 along the top and the keel 7 along the top pass through the corner code 18 and the corner code bolts 19 connections.

[0058] The thickness of the aluminum foam board 1 is 20mm, and the thickness of the wall is 120mm.

[0059] Except for the above-mentioned technical features, other structural technical ...

Embodiment 3

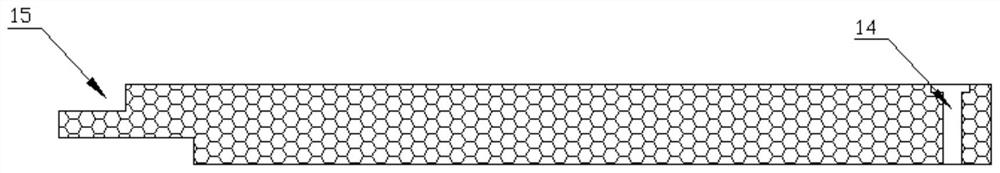

[0066] It can be seen from the accompanying drawings that the difference in structure between this embodiment and the foamed aluminum sound insulation wall of Embodiment 2 is that the outside of the foamed aluminum plate 1 is not sprayed with decorative patterns, but is attached with a metal panel 21, and the thickness of the metal panel 21 is 1 mm, the outer surface of the metal panel 21 is printed with a decorative pattern through thermal transfer printing, and the connection method between the metal panel 21 and the foamed aluminum plate 1 is fusion integral molding connection.

[0067]The construction method of the foamed aluminum sound insulation wall of the present embodiment is:

[0068] (1) Cutting of the aluminum foam board 1: the composite board with the metal panel 21 and the aluminum foam board 1 attached to the outside is cut into a plate with a width and thickness of 1000mm×800mm×12mm to ensure the four sides of the metal panel 21 and the aluminum foam board 1 com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com