Construction method of prestressed pipe pile reinforcing system on soft soil

A technology of prestressed pipe piles and construction methods, applied in the direction of soil protection, excavation, sheet pile walls, etc., to achieve the effects of saving materials, ensuring construction quality, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

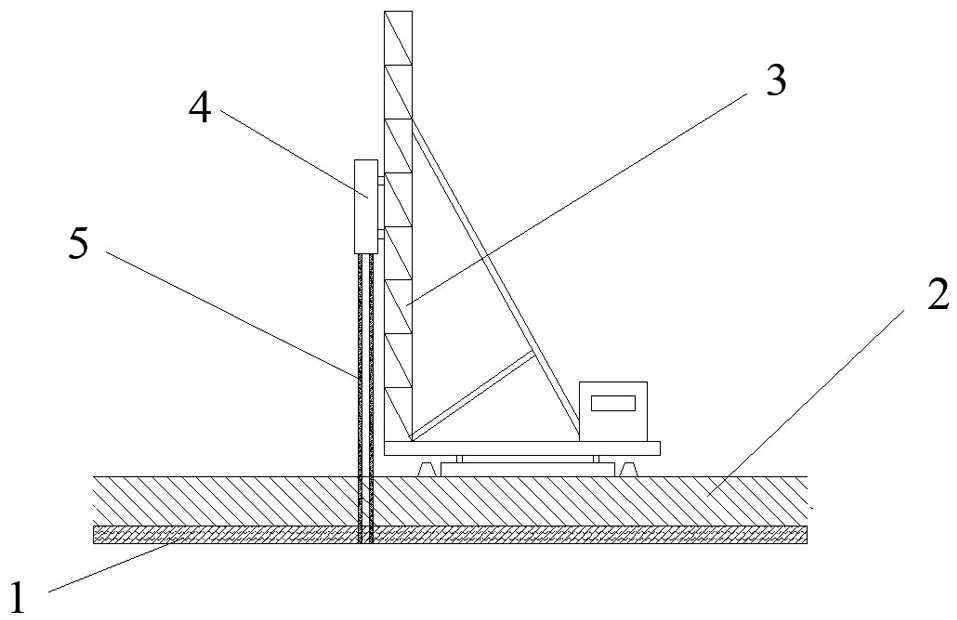

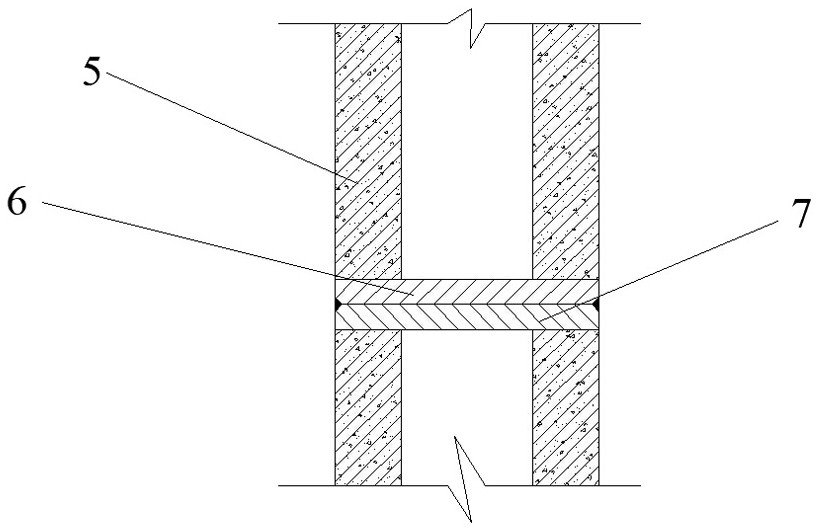

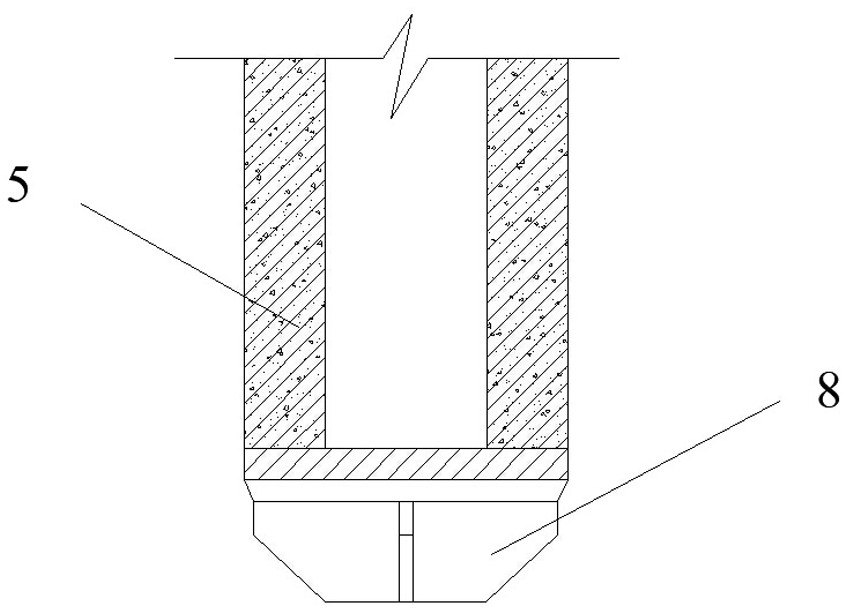

[0035] Taking the construction of a coastal area as an example, the soil in this area is soft soil foundation. In order to ensure the normal construction of the building, the soft soil foundation needs to be treated. Such as Figure 1 to Figure 4 As shown, it is processed by prestressed pipe pile reinforcement system on soft ground. The reinforcement system includes a building brick slag layer 2 on the soft soil layer 1, a hydraulic hammer 4 pile driver 3 installed on the building brick slag layer 2, a floor cushion 9 above the building brick slag layer 2, and building bricks The prestressed pipe pile 5 in the slag layer 2 and the soft soil layer 1; the top of the prestressed pipe pile 5 is connected with a cap; the hydraulic hammer 4 of the pile driver 3 has a hydraulic hammer 4 model of HHP14 with an impact mass of 14 tons, and the pipe pile is For PHC500-100AB type, the pile point 8 is B1 type, which increases the rock penetration capacity of pipe piles. Over-excavate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com