Layered stripping device for aged asphalt on surface of recycled asphalt pavement material

A pavement material and surface aging technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of high labor intensity, time-consuming and laborious, and low efficiency of manual stripping, and achieve the effect of high degree of automation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

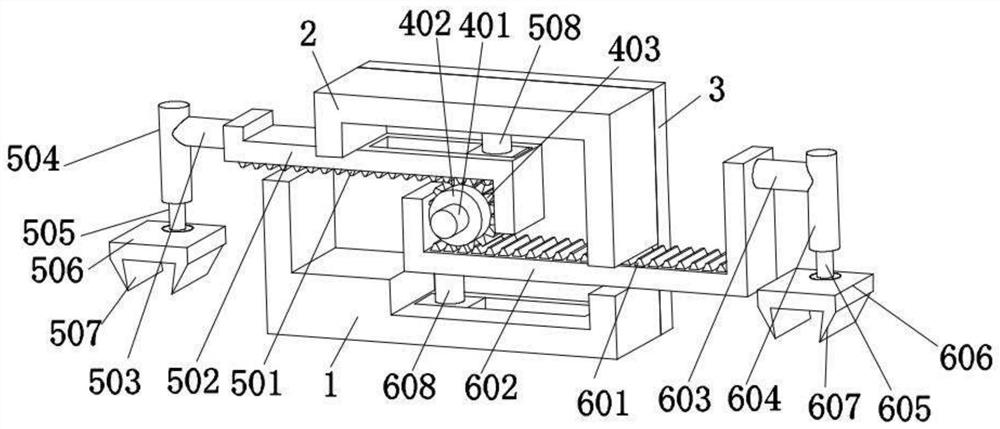

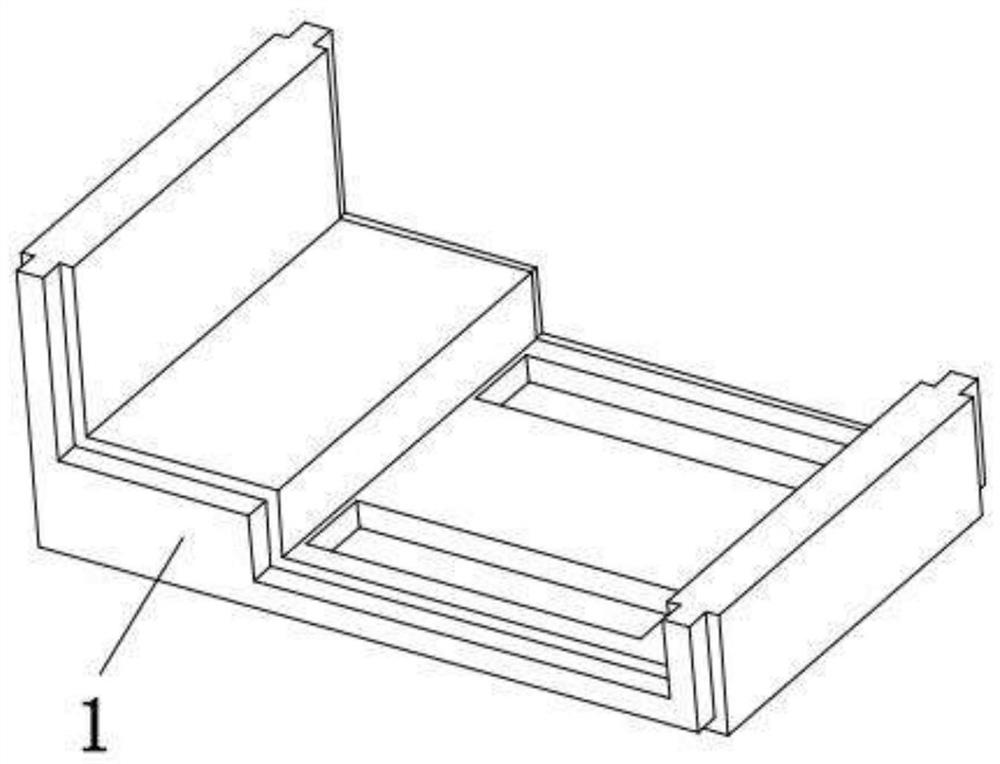

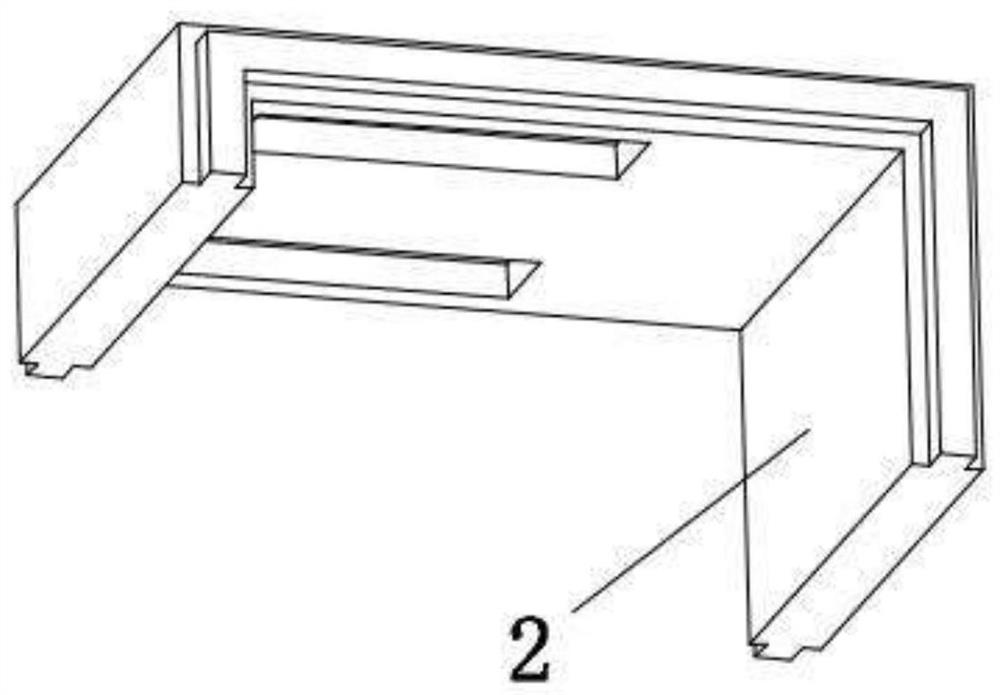

[0030] see Figure 1-7 A device for stripping aged asphalt layers on the surface of recycled asphalt pavement materials, comprising a bottom frame 1, a top frame 2 is arranged above the bottom frame 1, and a sealing plate 3 is detachably installed on the outer end surfaces of the bottom frame 1 and the top frame 2. A driving mechanism 4 is installed between the frame 1 and the top frame 2, and the driving mechanism 4 is connected with a first peeling mechanism 5 and a second peeling mechanism 6 through transmission.

[0031] Specifically, the outer end surfaces of the bottom frame 1 and the top frame 2 are fixedly equipped with protrusions, and the inner end surface of the sealing plate 3 is provided with sinking grooves. Inside, the connection stability between the bottom frame 1 and the top frame 2 and the sealing plate 3 can be ensured through the cooperation of the bump and the sealing plate 3, and the protection performance of the internal components can be realized under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com