Production process of feed-grade zinc glutamate

A zinc glutamate and production process technology, which is applied in the field of feed-grade zinc glutamate production process, can solve the problems of being difficult to apply to actual production, heavy pollution, and high energy consumption, and achieve low equipment cost and low process energy consumption , no effects of the three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

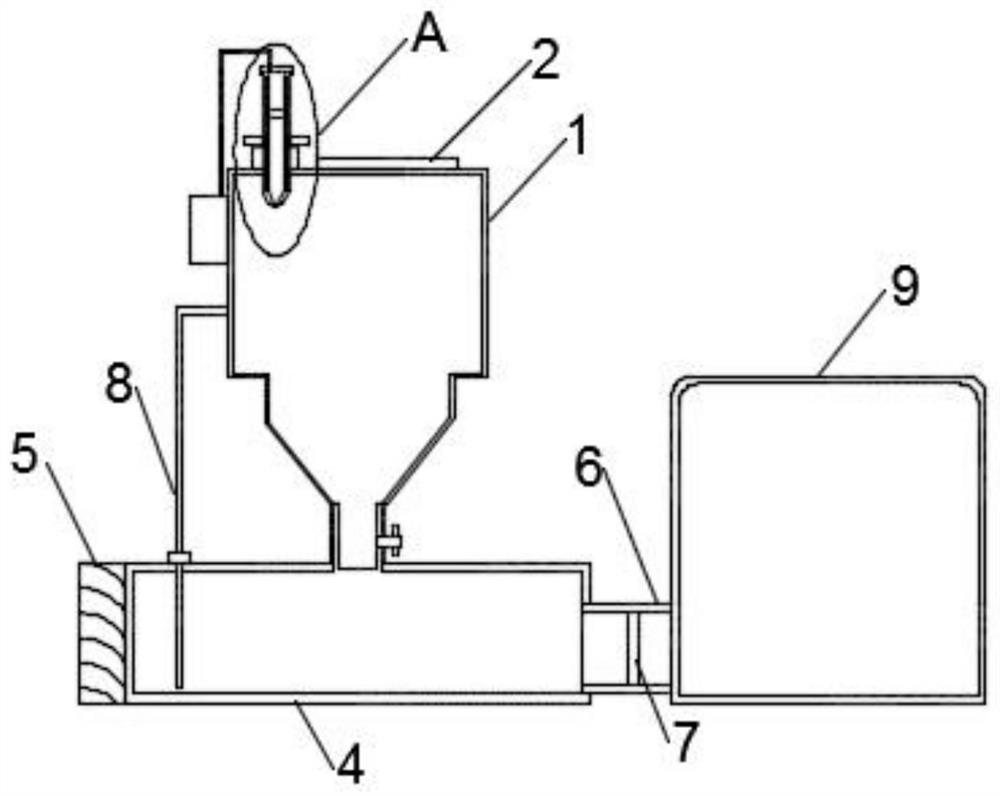

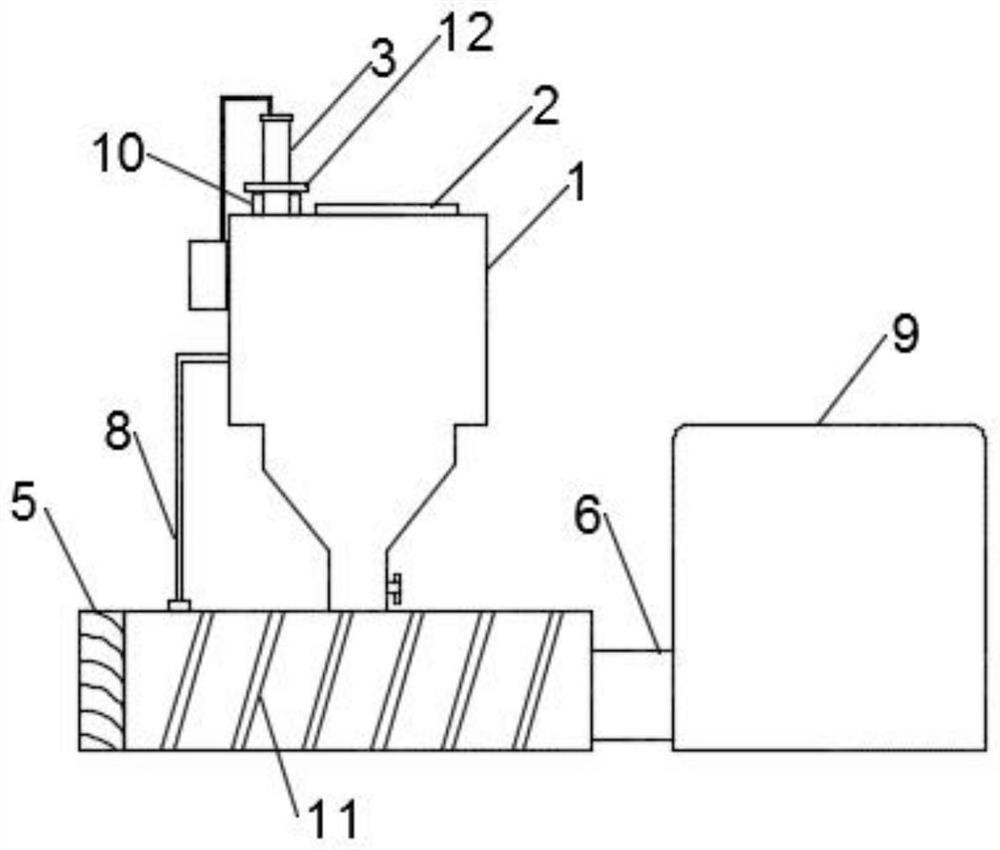

[0028] see Figure 1-5 :

[0029] (1) Open the first sealing cover 2, and close the first sealing cover 2 after adding deionized water and feed-grade glutamic acid in the reactor 1;

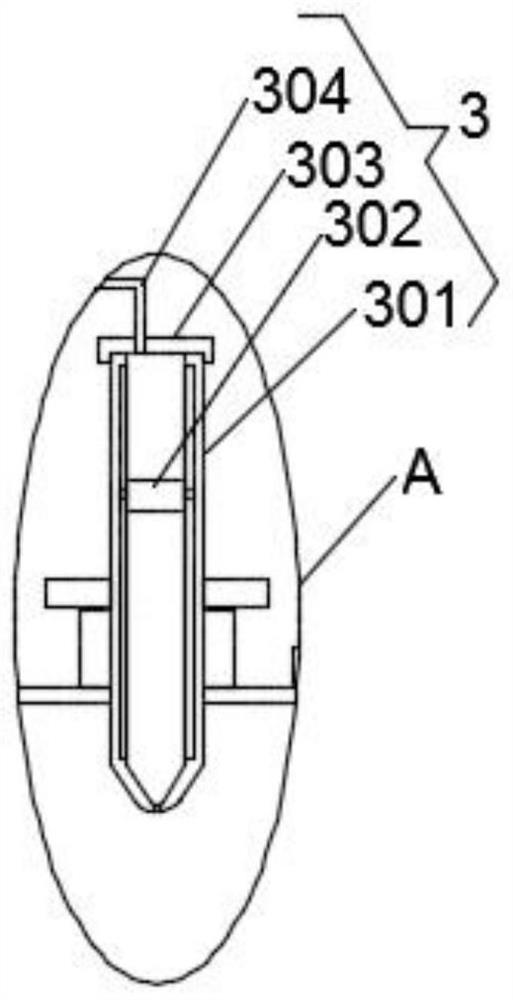

[0030] (2) Open the second closing cover 303, add zinc oxide solution in the slow injection tube 301, close the second closing cover 303, and move down the pressing plug 302 to push out the zinc oxide to the first connecting tube 304 by inputting positive pressure. In Reactor 1, the molar ratio of total zinc content to glutamic acid is 1:1, stir in Reactor 1 and heat up to 55°C;

[0031] (3) continue to heat up, control reaction temperature 75 ℃, keep warm for 30min, make raw material generate zinc glutamate chelate through sufficient reaction;

[0032] (4) Stop heating, open the valve at the output port of reactor 1, and the material is transferred into the crystallization tank 4 under the action of gravity, and the temperature in the crystallization tank 4 is reduced to 25° C. by passing cold...

Embodiment 2

[0036] see Figure 1-5 :

[0037] (1) Open the first sealing cover 2, and close the first sealing cover 2 after adding deionized water and feed-grade glutamic acid in the reactor 1;

[0038] (2) Open the second closing cover 303, add zinc oxide solution in the slow injection tube 301, close the second closing cover 303, and move down the pressing plug 302 to push out the zinc oxide to the first connecting tube 304 by inputting positive pressure. In Reactor 1, the molar ratio of total zinc content to glutamic acid is 1:1, stir in Reactor 1 and heat up to 60°C;

[0039] (3) continue to heat up, control reaction temperature 80 ℃, keep warm for 30min, make raw material generate zinc glutamate chelate through sufficient reaction;

[0040] (4) Stop heating, open the valve at the output port of reactor 1, and the material is transferred into the crystallization tank 4 under the action of gravity, and the temperature in the crystallization tank 4 is reduced to 28° C. by passing cold...

Embodiment 3

[0044] see Figure 1-5 :

[0045] (1) Open the first sealing cover 2, and close the first sealing cover 2 after adding deionized water and feed-grade glutamic acid in the reactor 1;

[0046] (2) Open the second closing cover 303, add zinc oxide solution in the slow injection tube 301, close the second closing cover 303, and move down the pressing plug 302 to push out the zinc oxide to the first connecting tube 304 by inputting positive pressure. In Reactor 1, the molar ratio of total zinc content to glutamic acid is 1:1, stir in Reactor 1 and heat up to 65°C;

[0047] (3) continue to heat up, control reaction temperature 85 ℃, keep warm for 30min, make raw material generate zinc glutamate chelate through sufficient reaction;

[0048] (4) Stop heating, open the valve at the output port of reactor 1, and the material is transferred into the crystallization tank 4 under the action of gravity, and the temperature in the crystallization tank 4 is reduced to 30° C. by passing cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com