Treatment method for dye wastewater

A treatment method and dye wastewater technology, applied in the direction of neutralization water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of ammonia nitrogen exceeding the standard, calcium carbonate cannot be recycled, large activated carbon, etc. , to achieve the effects of less organic residues, equipment corrosion resistance, low automation requirements, and low wastewater requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

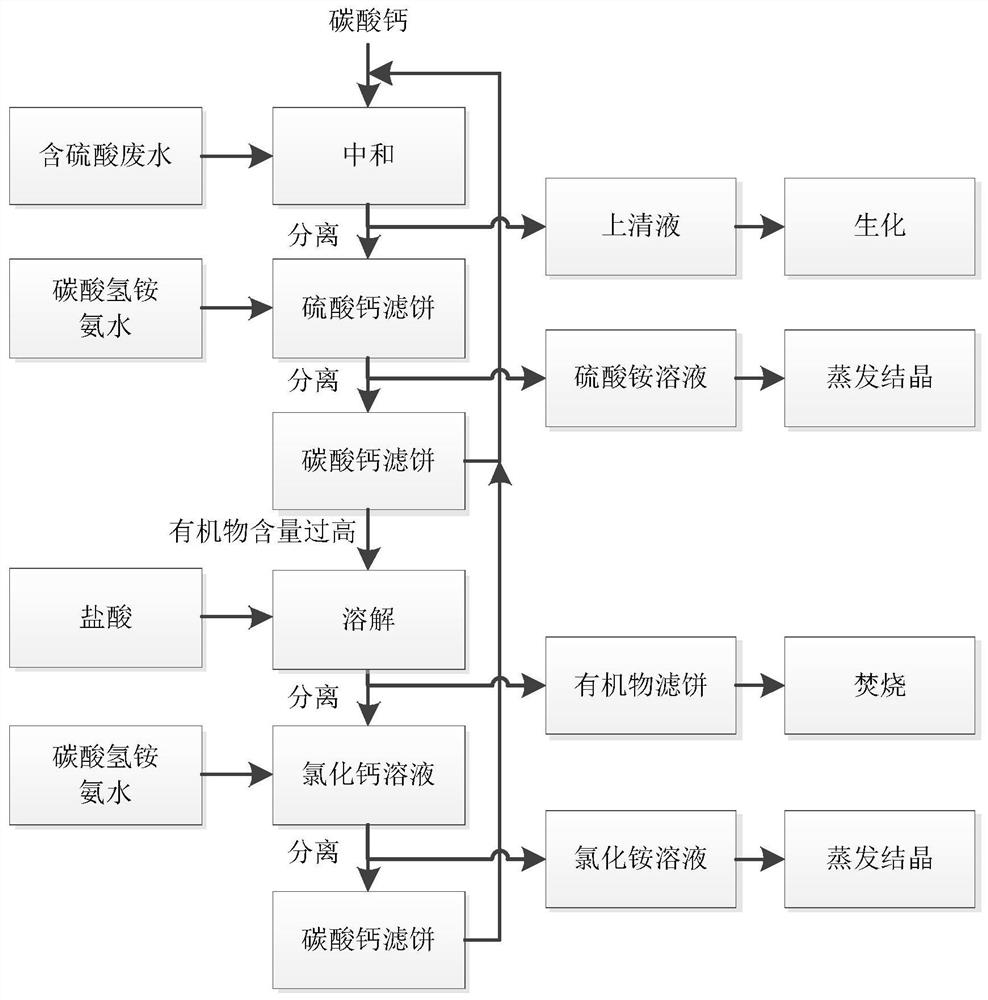

Method used

Image

Examples

Embodiment 1

[0063] In a large dye company in Zhejiang, the sulfuric acid wastewater produced during the dye production process contains about 2.6wt% sulfuric acid and a COD of 4800mg / L. Include the following steps:

[0064] Step 1. Neutralize the sulfuric acid-containing wastewater in batches with light calcium carbonate (content 97%) (subsequent neutralization with the calcium carbonate filter cake obtained from the reaction, and supplement with new calcium carbonate) to obtain a suspension, and control the pH of the neutralization end point = 4.0 to 5.0.

[0065] Step 2, separating the suspension obtained in step 1 by hydraulic filtration to obtain the first solid product (calcium sulfate filter cake) and a clear liquid with low salt content. The water content of the calcium sulfate filter cake is 45%; the COD of the clear liquid with low salt content is 1630 mg / L, and the salt content is less than 0.5%, and the clear liquid can be used for biochemical treatment.

[0066] Step 3. Slur...

Embodiment 2

[0074] In a dye company in Zhejiang, the sulfuric acid wastewater produced during the dye production process contained about 7.1% sulfuric acid and COD was 14000mg / L. Include the following steps:

[0075] Step 1. Neutralize the sulfuric acid-containing wastewater in batches with light calcium carbonate (97% content) (subsequent neutralization with the calcium carbonate filter cake obtained from the reaction, and supplement with new calcium carbonate) to obtain a suspension and control the neutralization end point pH=4.0~5.0.

[0076] Step 2, separating the suspension obtained in step 1 by hydraulic filtration to obtain the first solid product (calcium sulfate filter cake) and a clear liquid with low salt content. Wherein the first solid product (calcium sulfate filter cake) contains 50% water; the clear liquid with low salt content has a COD of 3150 mg / L and a salt content of less than 0.5%, and the clear liquid can be used for biochemical treatment.

[0077] Step 3. Beat th...

Embodiment 3

[0085] In a dye company in Zhejiang, the sulfuric acid wastewater produced during the dye production process contained about 4.8% sulfuric acid and COD was 8500mg / L. Include the following steps:

[0086] Step 1. Neutralize the sulfuric acid-containing wastewater in batches with light calcium carbonate (97% content) (subsequent neutralization with the calcium carbonate filter cake obtained from the reaction, and supplement with new calcium carbonate) to obtain a suspension and control the neutralization end point pH=4.0~5.0.

[0087]Step 2, separating the suspension obtained in step 1 by hydraulic filtration to obtain the first solid product (calcium sulfate filter cake) and a clear liquid with low salt content. Wherein the first solid product (calcium sulfate filter cake) contains 30% water; the clear liquid COD of low salt content is 2650mg / L, and the salt content is less than 0.5%, and this clear liquid can be used for biochemical treatment.

[0088] Step 3. Beat the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com