Rotary filling machine for meat processing

A meat processing and filling machine technology, applied in meat processing equipment, bottling machines, processed meat, etc., can solve problems such as increasing production costs, meat quality rot, etc., reducing costs, improving efficiency, and improving smoothness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

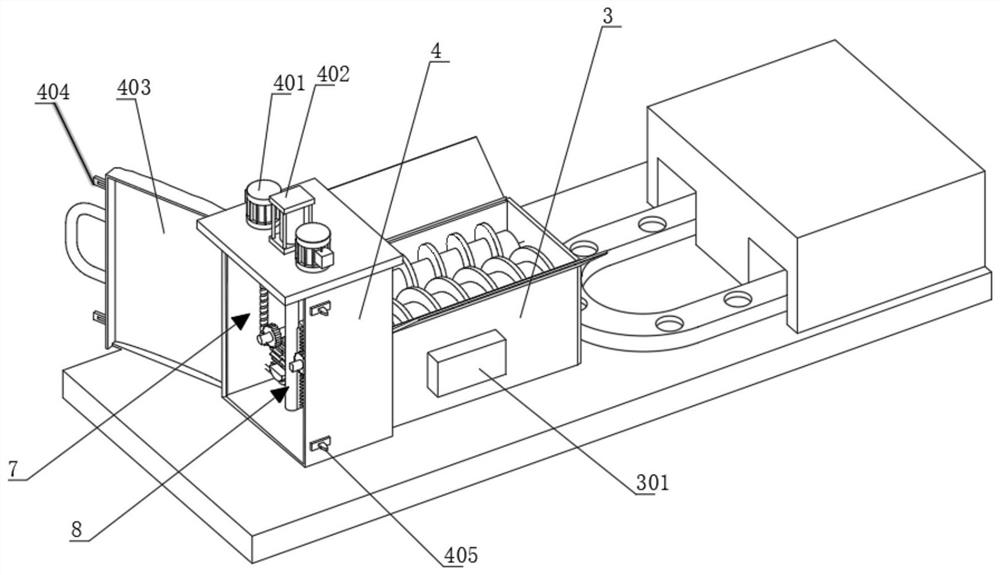

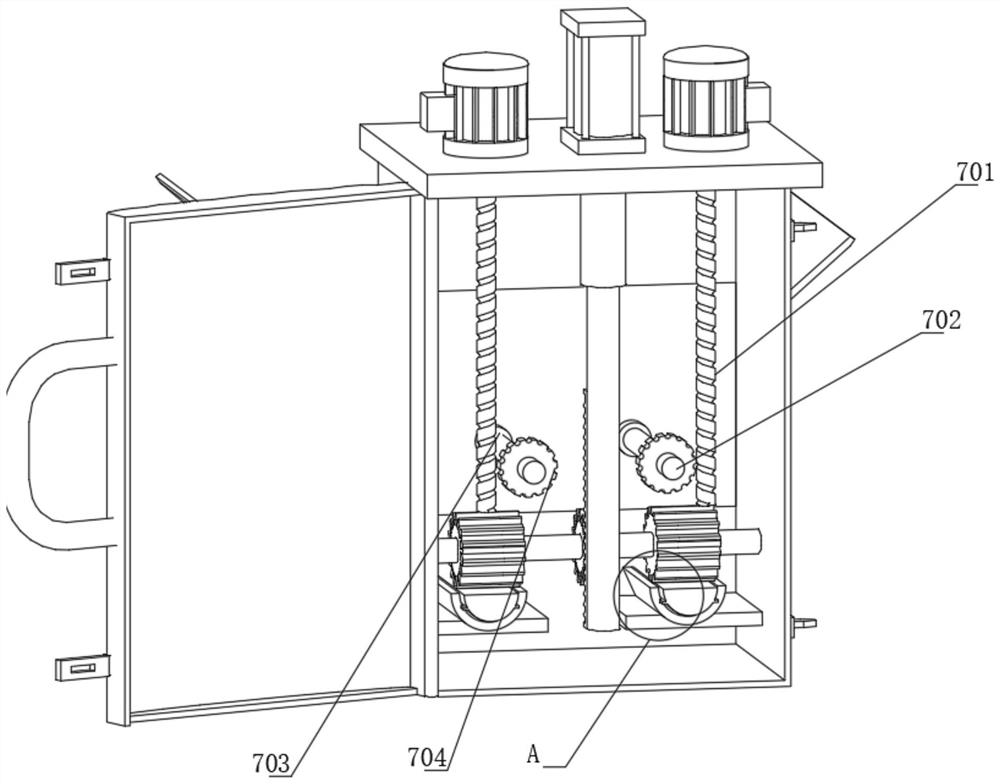

[0029] Such as Figure 1-7 As shown, a rotary filling machine for meat processing includes a support base plate 2, and a control cabinet 4, a processing cabinet 3, a conveyor belt 10, a capping machine 1, and a capping machine 1 are sequentially installed on one side of the upper surface of the support base plate 2 Set on the side away from the control case 4, the center of the upper surface of the control case 4 is fixedly installed with the cylinder 402, the upper surface of the control case 4 is located on both sides of the cylinder 402, and the motors 401 are installed, and the output shafts of the motors 401 on both sides are correspondingly connected to the control case 4 The worm gear and worm driving assembly 7 arranged inside, the output shaft of the cylinder 402 is cooperatively connected with the gear plate and gear driving assembly 8 arranged inside the control cabinet 4, and both worm gear and worm drive assemblies 7 pass through the adjacent side of the control ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com