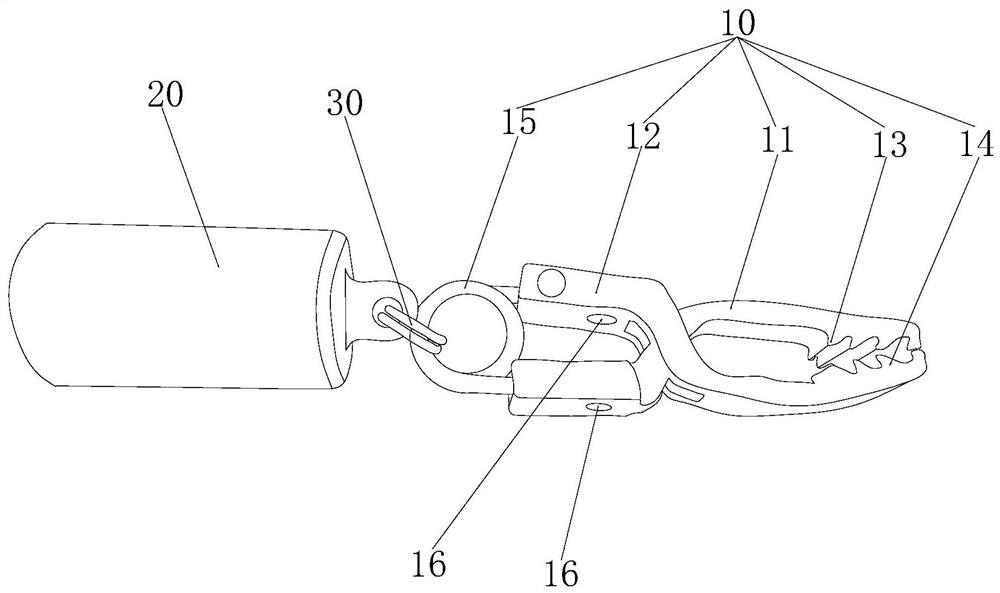

Tissue clamp assembly and clamp forceps

A technology of tissue clips and components, applied in surgical forceps, medical science, surgery, etc., can solve problems such as collision interference and affecting the normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

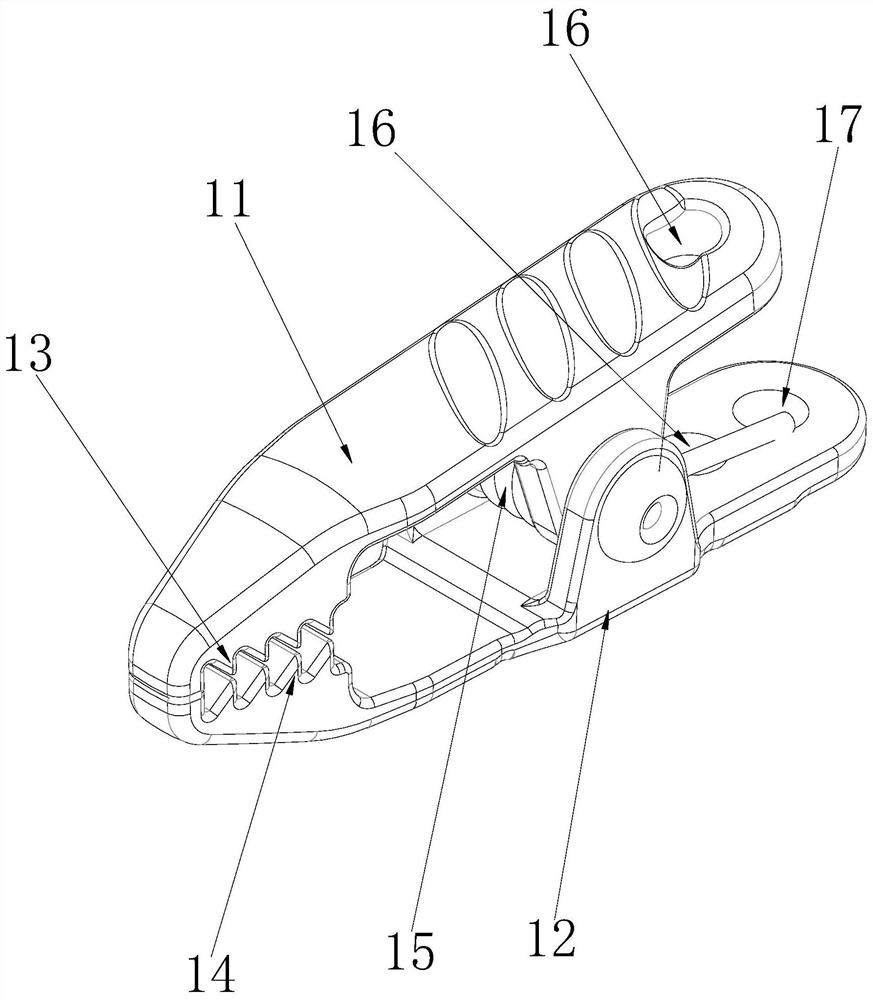

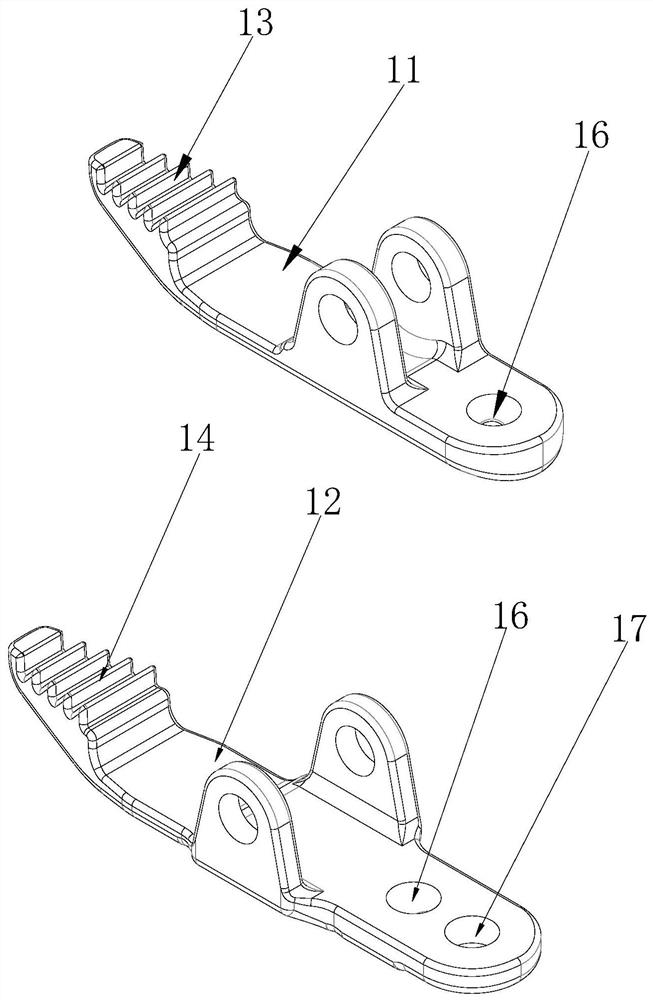

Embodiment 1

[0037] In this embodiment, the first toothed chuck 13 and the second toothed chuck 14 are multiple; the first toothed chuck 13 and the second toothed chuck 14 are all bar teeth, and the first toothed Chuck 13 extends along the width direction of first clamping arm 11, and a plurality of first toothed chucks 13 are arranged at intervals along the length direction of first clamping arm 11 and are parallel to each other; 12 extends in the width direction, and a plurality of second toothed chucks 14 are arranged at intervals along the length direction of the second clamp arm 12 and are parallel to each other; a plurality of first toothed chucks 13 and a plurality of second toothed chucks 14 are arranged along the The positions in the longitudinal direction of the first clamping arm 11 or the second clamping arm 12 correspond one to one. The tooth tips of the chucks 14 face up and down one by one, and the distance between the tooth tips of each pair of the first toothed chuck 13 an...

Embodiment 2

[0041] In this embodiment, the first toothed chuck 13 and the second toothed chuck 14 are multi-row, and each row of the first toothed chuck 13 and the second toothed chuck 14 are multiple; The first toothed clamps 13 are arranged at intervals along the length direction of the first clamp arm 11, and a plurality of first toothed clamps 13 of each row are arranged at intervals along the width direction of the first clamp arm 11; the second toothed clamps of multiple rows The heads 14 are arranged at intervals along the length direction of the second clamping arm 12 , and a plurality of second toothed chucks 14 in each row are arranged at intervals along the width direction of the second clamping arm 12 .

[0042] The number of the first toothed chuck 13 or the second toothed chuck 14 of each row is not equal, and the width of the first clamping portion and the second clamping portion is along the rear of the first clamping arm 11 or the second clamping arm 12. The direction fro...

Embodiment 3

[0046] In this embodiment, the first toothed chuck 13 and the second toothed chuck 14 are multi-row, and each row of the first toothed chuck 13 and the second toothed chuck 14 are multiple; The first toothed clamps 13 are arranged at intervals along the length direction of the first clamp arm 11, and a plurality of first toothed clamps 13 of each row are arranged at intervals along the width direction of the first clamp arm 11; the second toothed clamps of multiple rows The head 14 is arranged at intervals along the length direction of the second clamping arm 12, and a plurality of second toothed chucks 14 of each row are arranged at intervals along the width direction of the second clamping arm 12; the first toothed chucks 13 of multiple rows and the multiple rows The position of the second toothed chuck 14 along the length direction of the first clamp arm 11 or the second clamp arm 12 corresponds one by one, and each row of multiple first toothed chucks 13 corresponds to a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com