Novel pulping and shelling device special for loquats

A loquat, a new type of technology, applied in the field of a new loquat special beating and shelling device, can solve the problem of juice impurity, and achieve the effect of avoiding hard extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

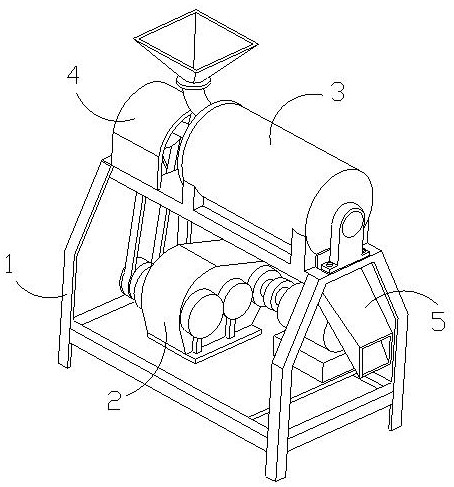

[0031] as attached figure 1 to attach Figure 7 Shown:

[0032] The present invention provides a new type of beating and shelling device specially used for loquat. Its structure is provided with a support base 1, a switchboard 2, a fuselage 3, a transmission frame 4, and a slag outlet 5. The fuselage 3 is installed at the top of the support base 1. The switchboard 2 is located below the fuselage 3, the transmission frame 4 is connected and movably coordinated with the switchboard 2, the slag outlet 5 is connected to the position below the side end of the fuselage 3, and the transmission frame 4 is connected to the fuselage 3. Set adjacently and coordinate activities.

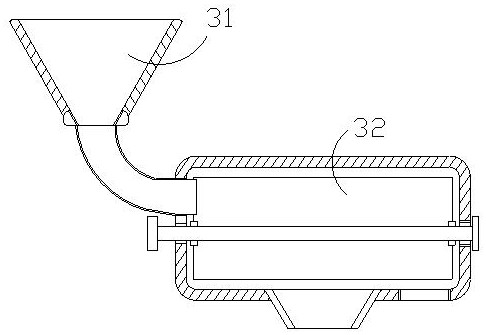

[0033] The fuselage 3 is provided with a hopper 31 and an operating cylinder 32 , the lower end of the hopper 31 is connected to and matched with one end of the operating cylinder 32 , and the operating cylinder 32 is clearance fit inside the fuselage 3 .

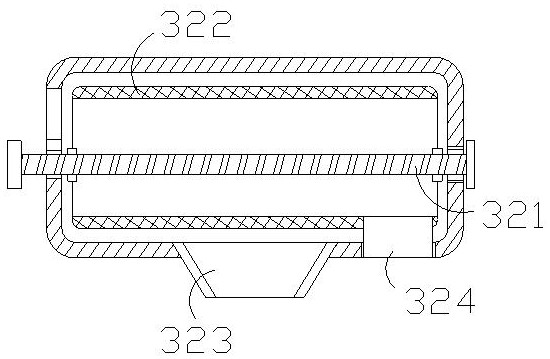

[0034] Wherein, the operating cylinder 32 is provide...

Embodiment 2

[0041] as attached Figure 8 to attach Figure 9 Shown:

[0042] Wherein, the briquetting block a23 is provided with a solid block w1, a rebound block w2, a rolling ball w3, and a movable cavity w4, the resilient block w2 is embedded and moved inside the solid block w1, and the movable cavity w4 is located in the solid block w1 Below, the rolling ball w3 moves in the movable cavity w4, the rebound block w2 is in the shape of a petal, and has good resilience, and the solid block w1 is a block made of hard silicone material, which has a certain Toughness, the rolling ball w3 is spherical and can be expanded and deformed, the rolling ball w3 rolls in the movable cavity w4, and exerts extrusion force on the solid block w1 and the rebounding block w2 to deform them At the same time, a jacking force is generated on it, which facilitates the cooperation of the solid block w1 and the resilient block w2, and exerts different extrusion forces on the external object during deformation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com