Full-scale fuel assembly anti-seismic test method and an anti-seismic test bed

A fuel assembly and anti-seismic test technology, which is applied in the testing of machine/structural components, vibration testing, measuring devices, etc., can solve the problem of no direct full-scale anti-seismic test of fuel assemblies, and achieve the effect of real data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

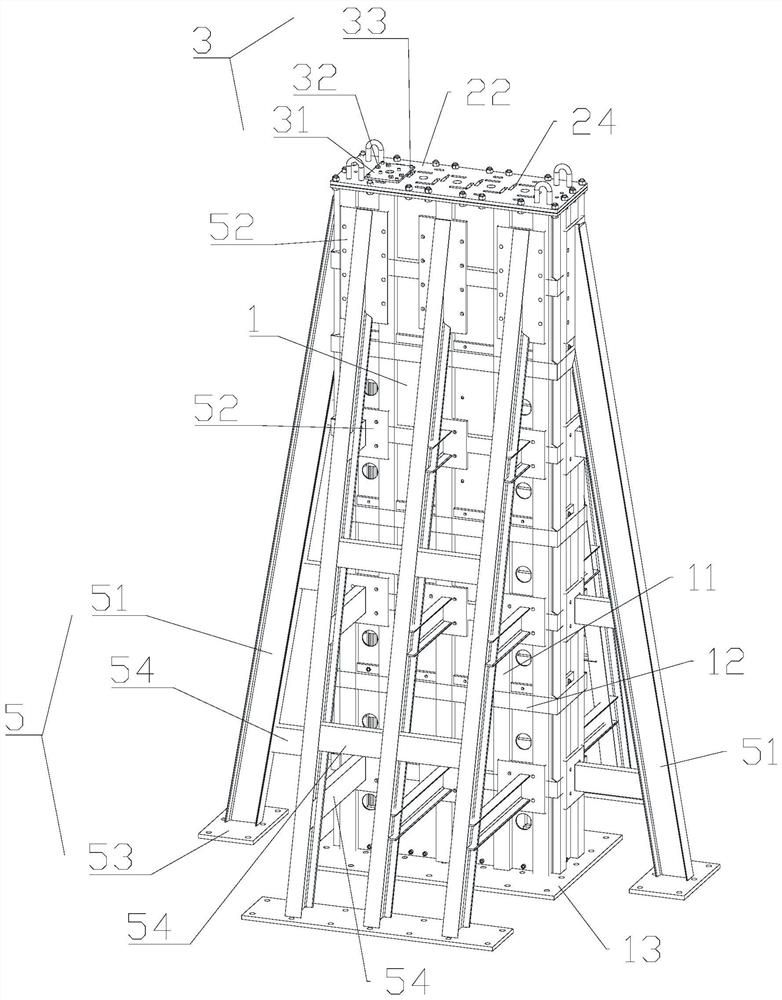

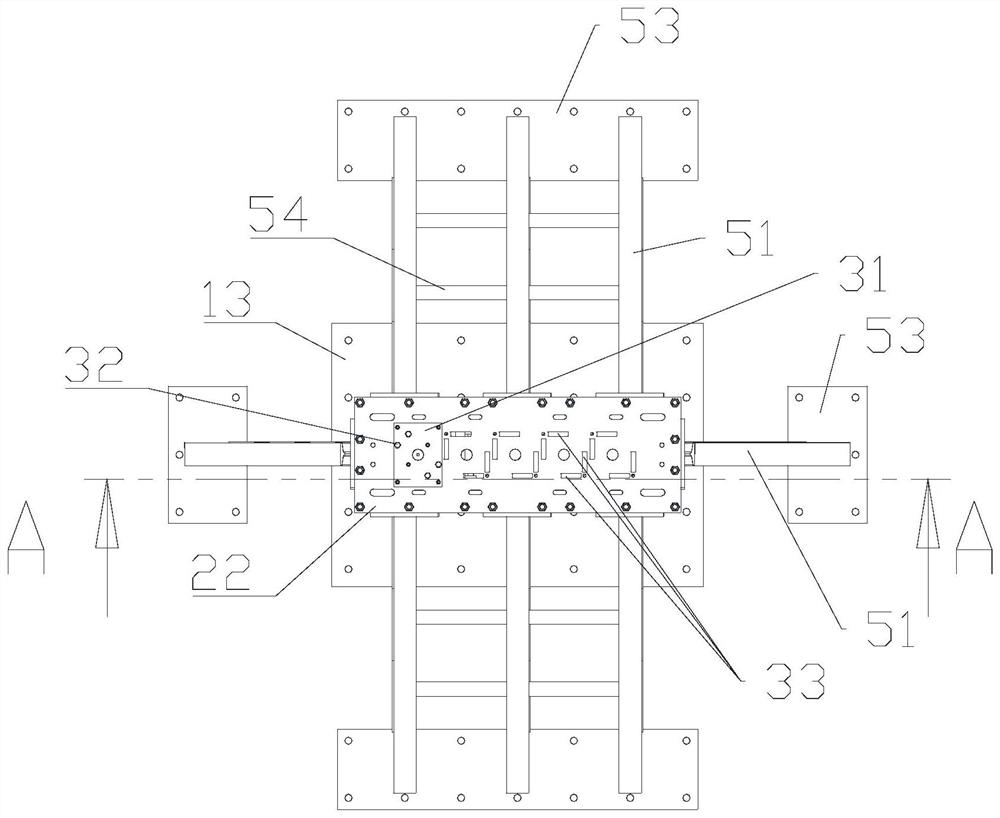

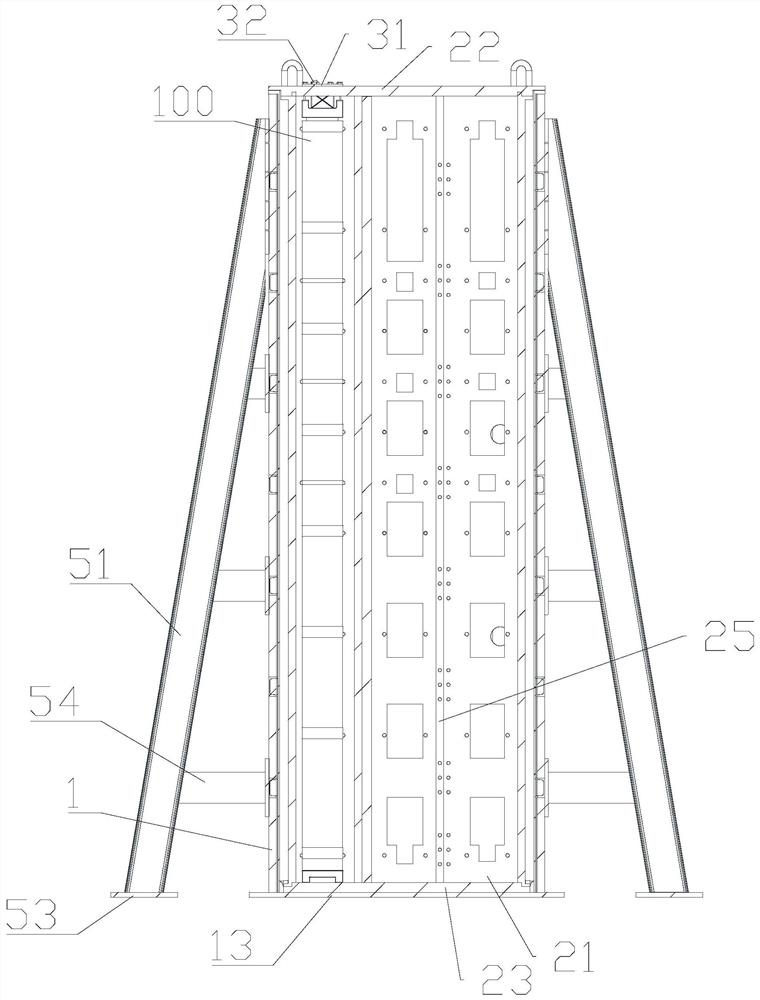

[0101] like figure 1 , figure 2 with Figure 10 Shown as an alternative embodiment of the present invention, the urging means 3 includes a platen 31, a preload adjusting bolt 32 and the groove 33; groove 33 defines biasing the upper core plate 22, and corresponds to the top of the fuel assembly the position of the plate spring 900, the pressure plate 31 anchored at the top of the upper core plate 22 and the slot 33 overlies preload adjusting bolt 32 anchored on the pressure plate 31, the spring and the end plate of the fuel assembly top 900 to provide a tight biasing The fuel plate assembly 900 so that the force urging the displacement of the spring to meet the design compression.

[0102] The present invention, by adjusting the platen and the top tube bolt tightening seat plate spring 900 on the fuel assembly, to meet the different requirements of preload pair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com