Combustion method for effectively reducing boiler furnace slagging and high-temperature corrosion

A boiler furnace, high-temperature corrosion technology, applied in the direction of combustion method, combustion control, combustion equipment, etc., can solve the problems of aggravated high-temperature corrosion of the water wall, deterioration of slagging of the water wall of the boiler furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

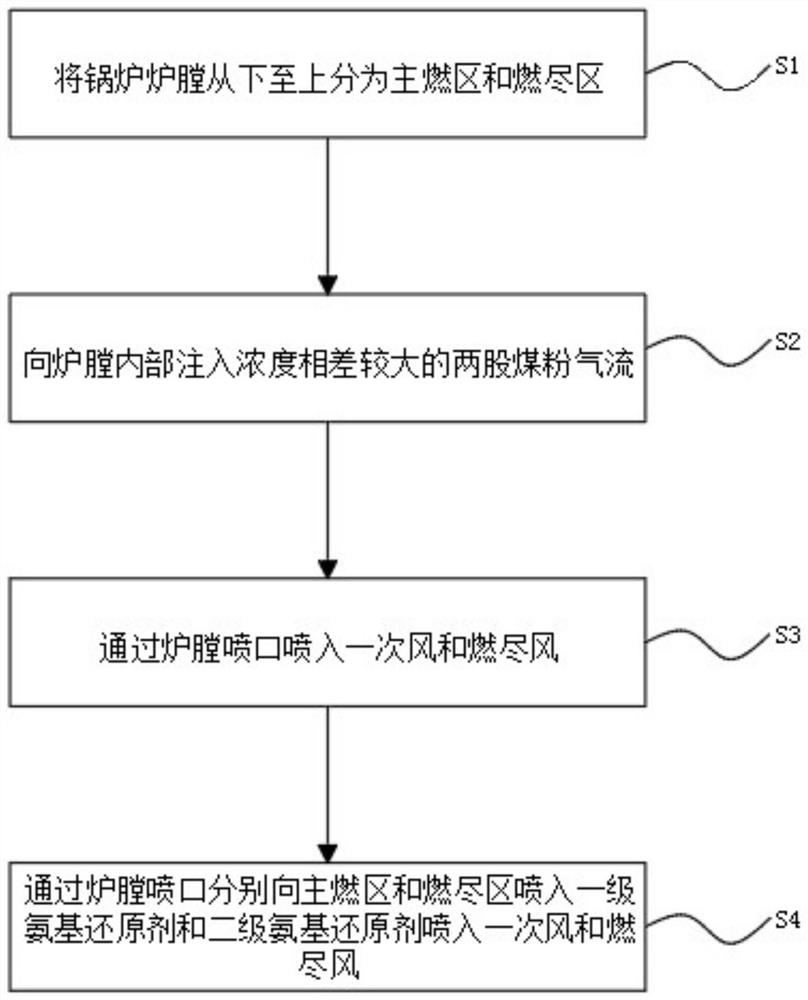

[0024] Please refer to the working principle diagram of the combustion method for effectively reducing boiler furnace slagging and high-temperature corrosion provided by the present invention. Combustion methods to effectively reduce boiler furnace slagging and high-temperature corrosion include S1, dividing the boiler furnace from bottom to top into a main combustion zone and a burnout zone; S2, injecting two streams of pulverized coal with a large difference in concentration into the furnace; S3, Inject the primary air and the burnout air through the furnace spout; S4, spray the primary amino reducing agent and the secondary amino reducing agent into the main combustion zone and the burnout zone respectively.

[0025]In the specific implementation process, the boiler furnace is divided into the main combustion zone and the burnout zone from bottom to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com