Protection device for sewing machine based on textile finished product manufacturing

A technology for protection devices and sewing machines, which is applied to the protection devices of sewing machines, textiles and papermaking, and sewing machine components. It can solve the problems of potential safety hazards, lack of mandatory functions, and inability to be worn by sewing machine workers to achieve the effect of ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

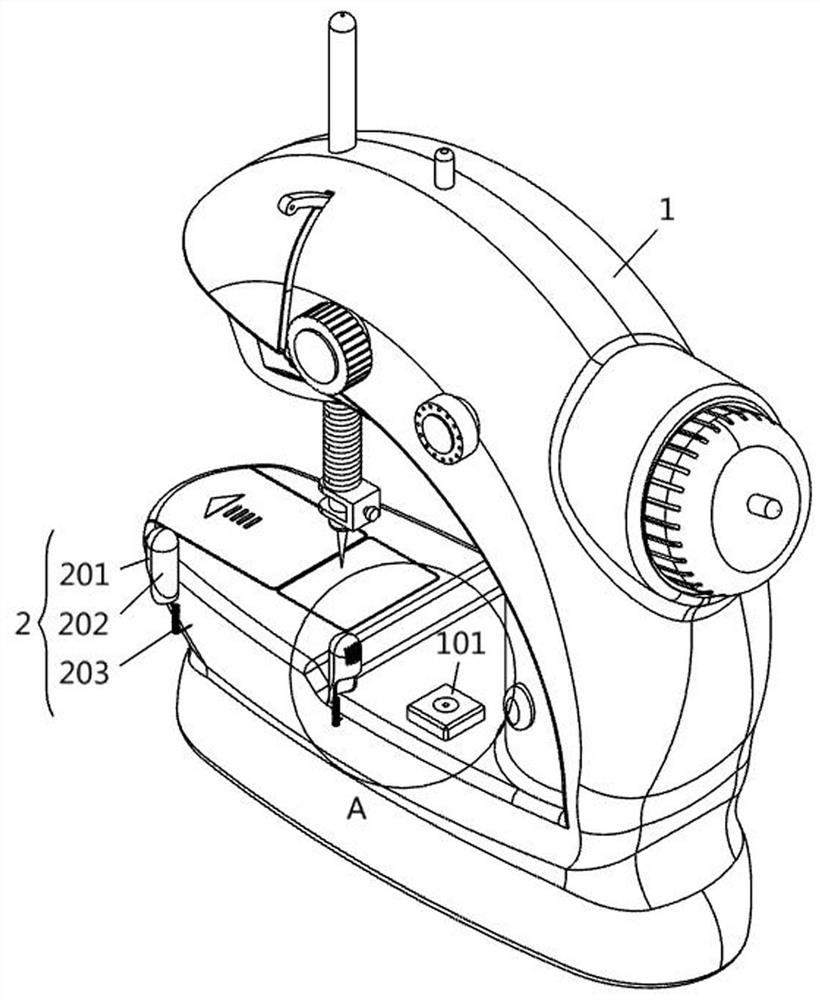

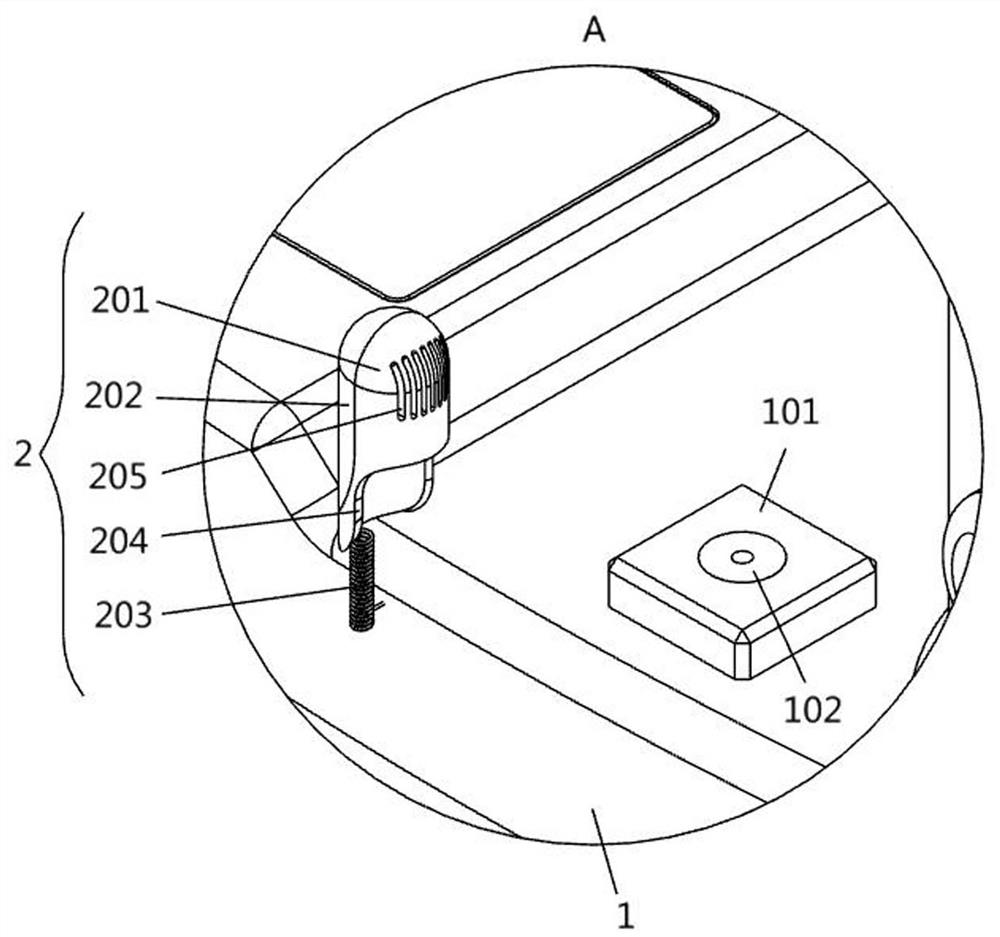

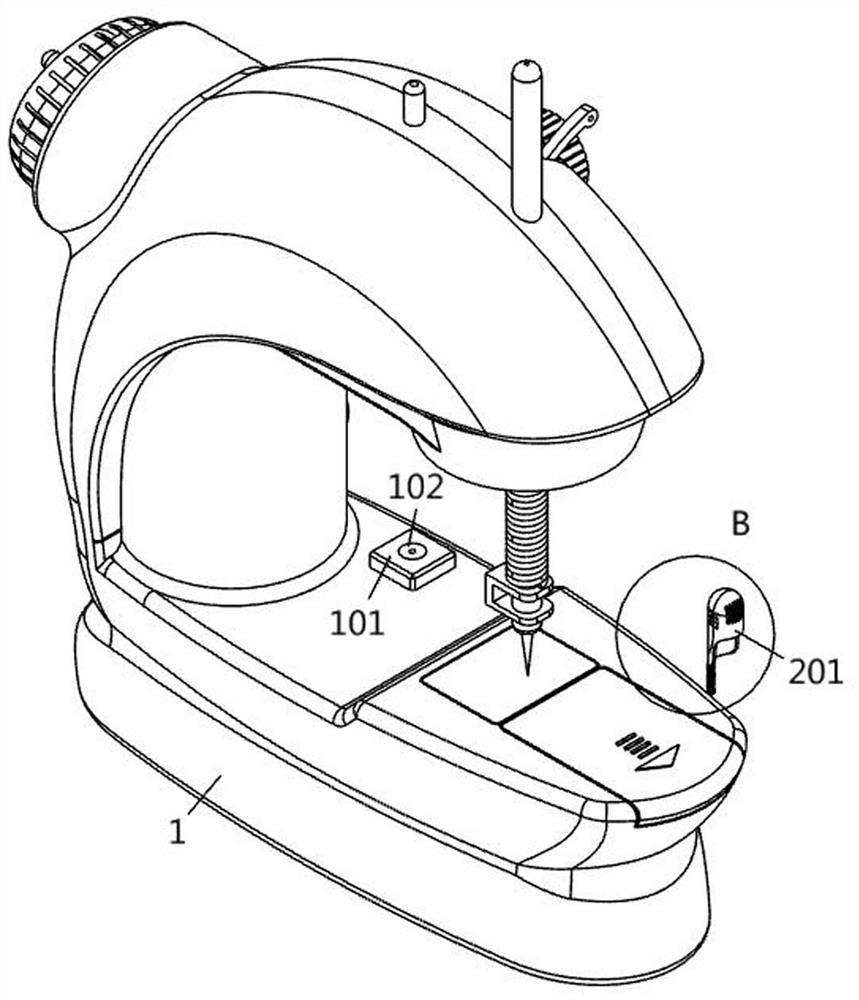

[0032] Append figure 1 Attachment Figure 8 Looking:

[0033] The present invention provides a sewing machine based on the textile articles produced by the protection apparatus, comprising: an electric sewing machine 2 and a protection mechanism, the protection mechanism 2 via the protective cover 201, a barrier layer 202, the wire 203, notched groove 204, vents 205, the contact member 206, the insert slot 207, accommodating groove 208, closing the transparent layer 209 and an infrared sensor composed 2010; protection mechanism 2 is provided with a total of two groups, two protective means 2 as a structure symmetrical shape, two protective means 2 are provided the electric sewing machine body 1 side adjacent to the front left and right sides of the needle bar; 201 form finger-shaped overall configuration of the protective cover, the protective cover 201 with plastic material, the protective cover 201 to the bottom peripheral surface defines a dome region there is a receiving groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com