Intelligent equipment for high-efficiency fishing rod throwing rod assembly and assembly method

An assembly method and high-efficiency technology, applied in transportation and packaging, conveyor control devices, conveyors, etc., can solve the problems of factories not recruiting people and hindering production, and achieve the effect of improving production efficiency and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

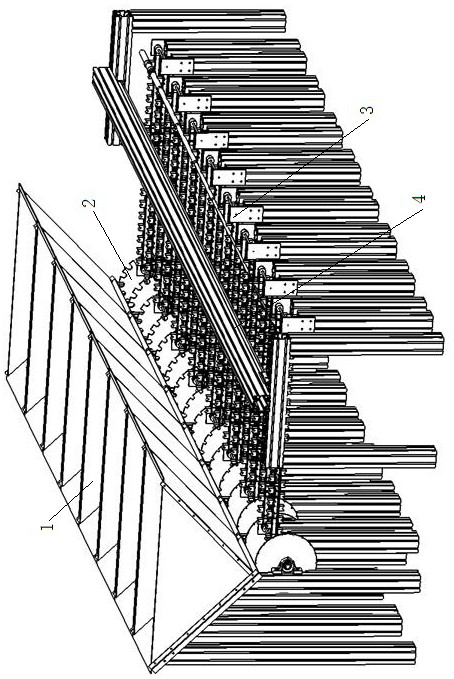

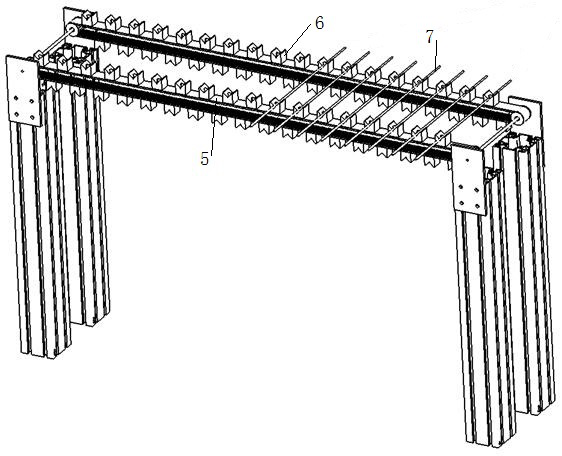

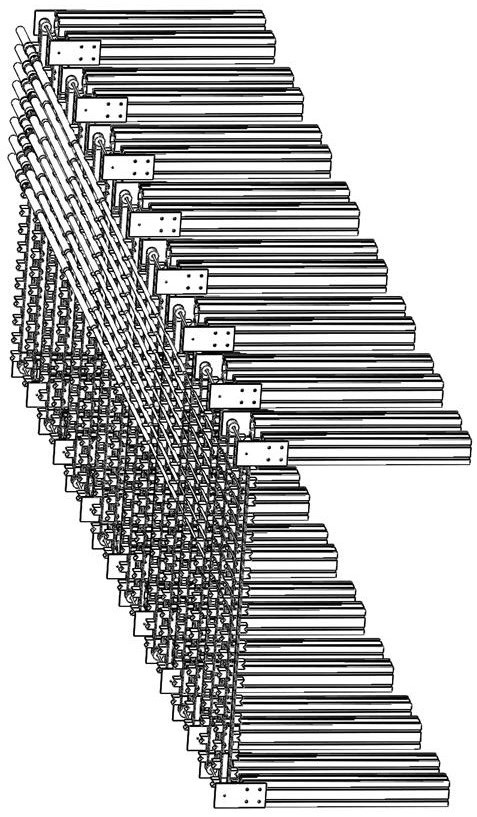

[0025] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0026] A high-efficiency fishing rod throwing rod assembly method is characterized in that it includes the following steps:

[0027] 1. Set up a belt conveyor with the same number of rods as required for a throwing rod, and arrange the belt conveyors in sequence along the X direction. There are two conveyor belts arranged along the X direction on the belt conveyor. And the driving device that drives the conveyor belt to rotate. The conveying direction of the conveyor belt is the Y direction perpendicular to the X direction. A number of support blocks arranged in sequence along the Y direction are fixed on the conveyor belt. The upper surface of the support blocks is provided with V-shaped grooves. Each belt type The support blocks on the conveyor form several rows along the X direction, and the V-shaped grooves of the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com