Color sorter

A color sorter and camera technology, applied in the field of color sorter, can solve the problems of affecting the life of electrical components in the equipment, increasing the maintenance cost of the equipment, and the high power of the color sorter, so as to reduce the maintenance cost in the later period, improve the service life, and improve the The effect of recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

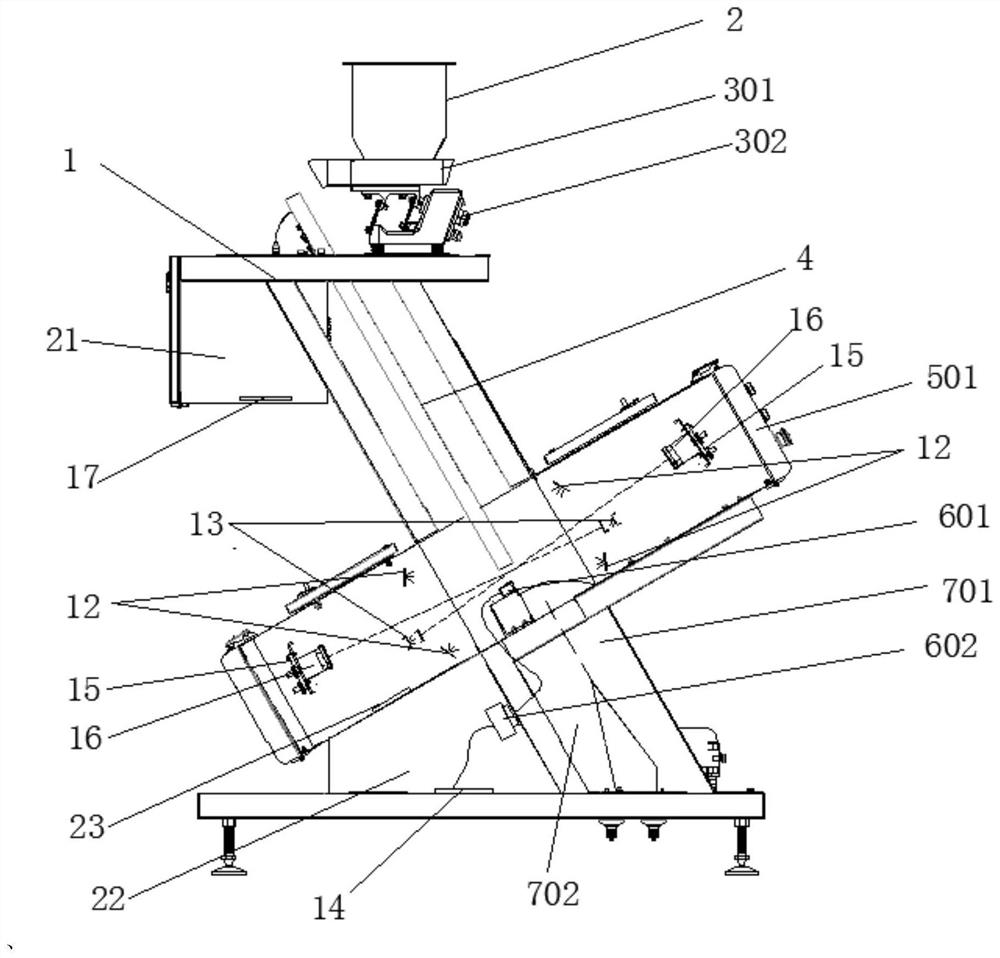

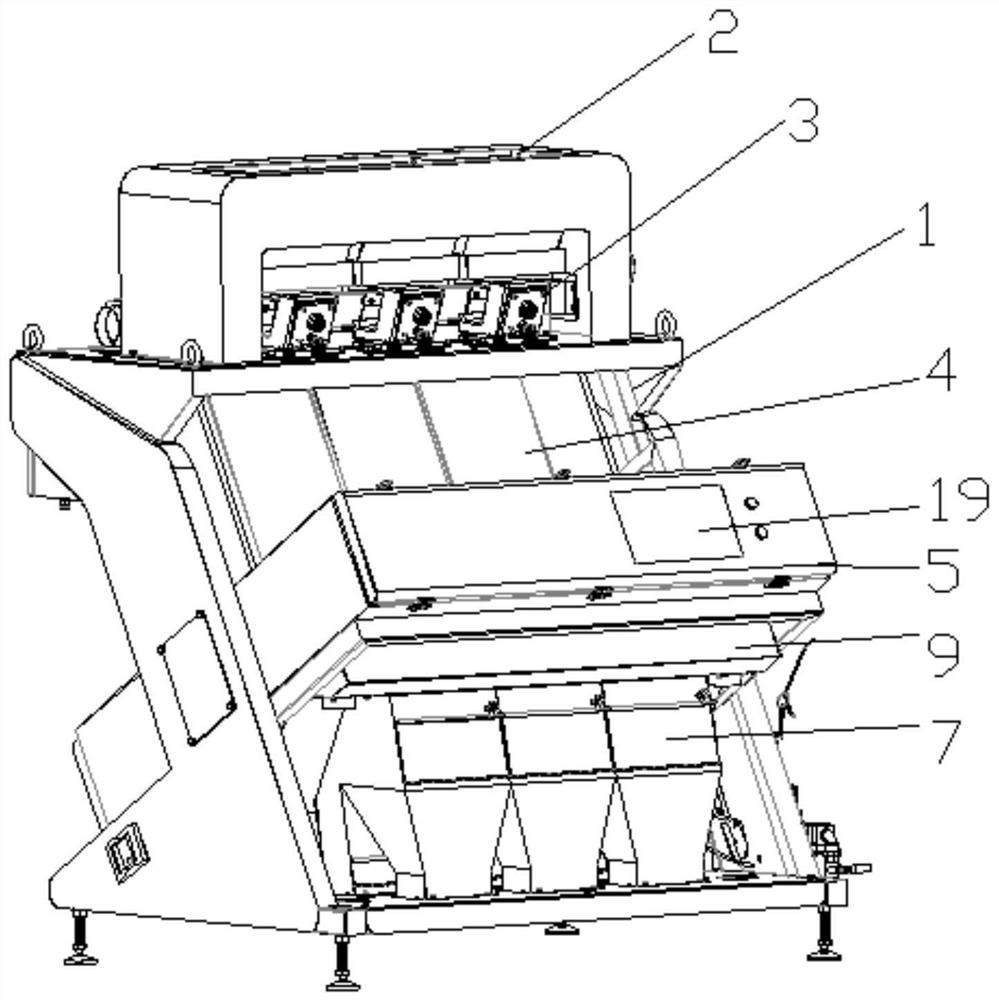

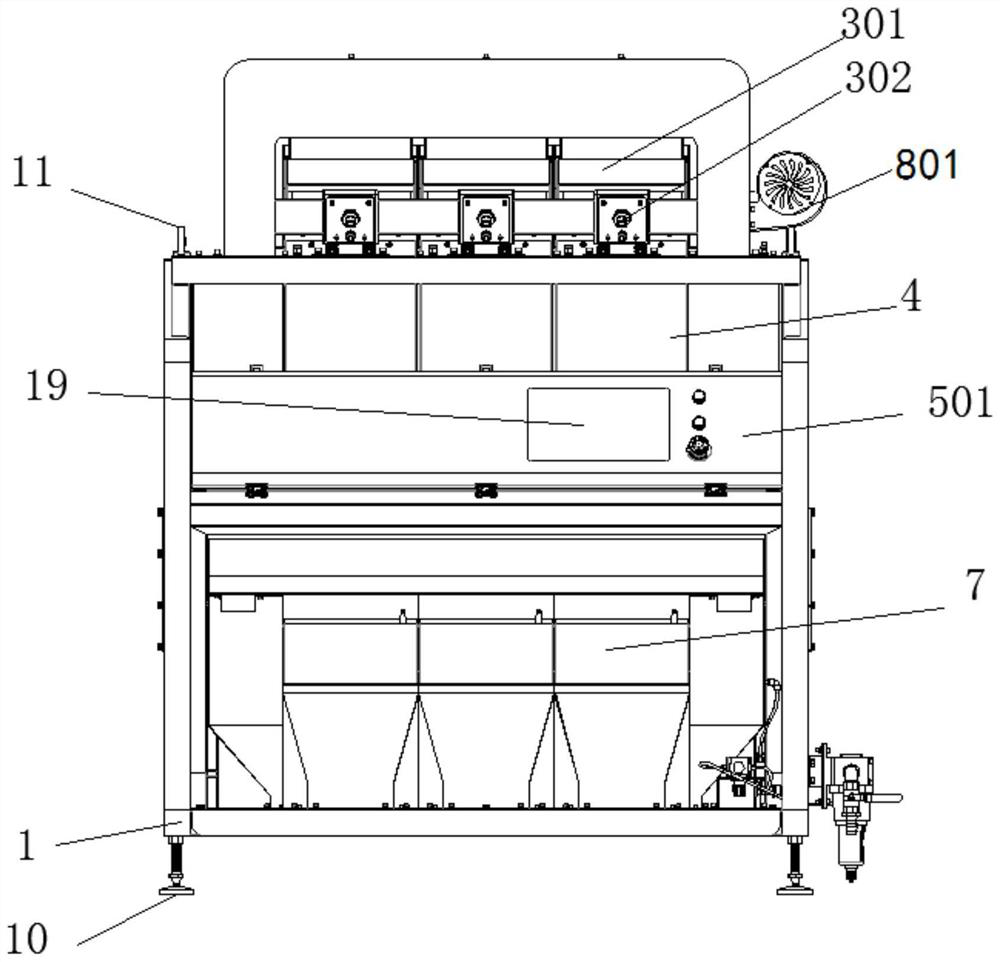

[0030] The embodiment of the present invention provides a color sorter, which clearly and completely describes the technical solution in the present invention. Obviously, the described embodiment is a part of the embodiment of the present invention and illustrates the internal technical structure. Those skilled in the art All other embodiments obtained under the premise of no creative work belong to the protection scope of the present invention.

[0031] Such as Figure 1-5 As shown, this embodiment provides a color sorter, including a main frame 1, a feed hopper 2, a vibrating feeding device 3, a chute 4, an optical sorting box 5, a material rejecting device 6, and a material sorting and discharging hopper 7 ; The above-mentioned equipment is fixed on the main frame 1, and the main frame 1 is used as the main support frame of the equipment. The feed hopper 2 is installed on the top of the main frame 1 to receive the materials to be sorted. The inside of the feed hopper 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com