Transformer

A technology for transformers and controllers, applied in the field of transformers, can solve problems such as the inability to dynamically increase the heat dissipation rate, the transformer cannot work normally, and shorten the service life of the transformer, so as to achieve the effects of unnecessary cooling usage, reasonable structure, and heat dissipation balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

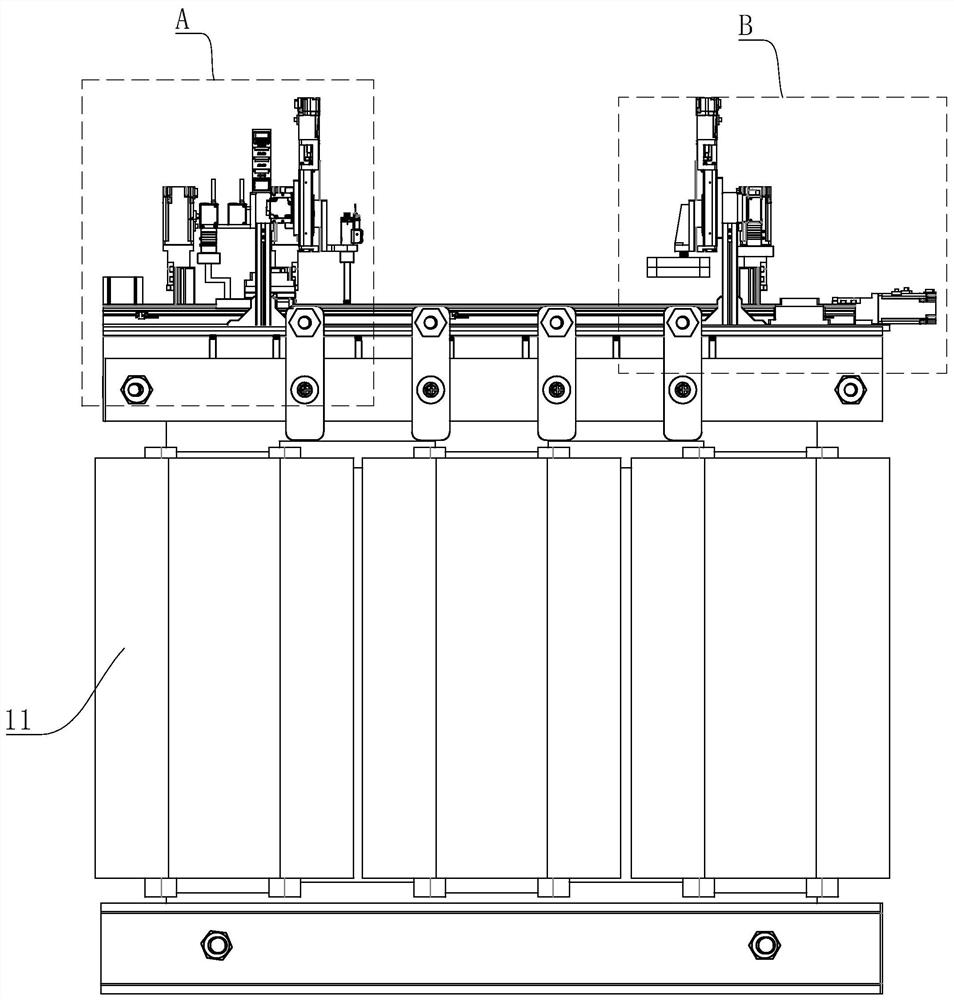

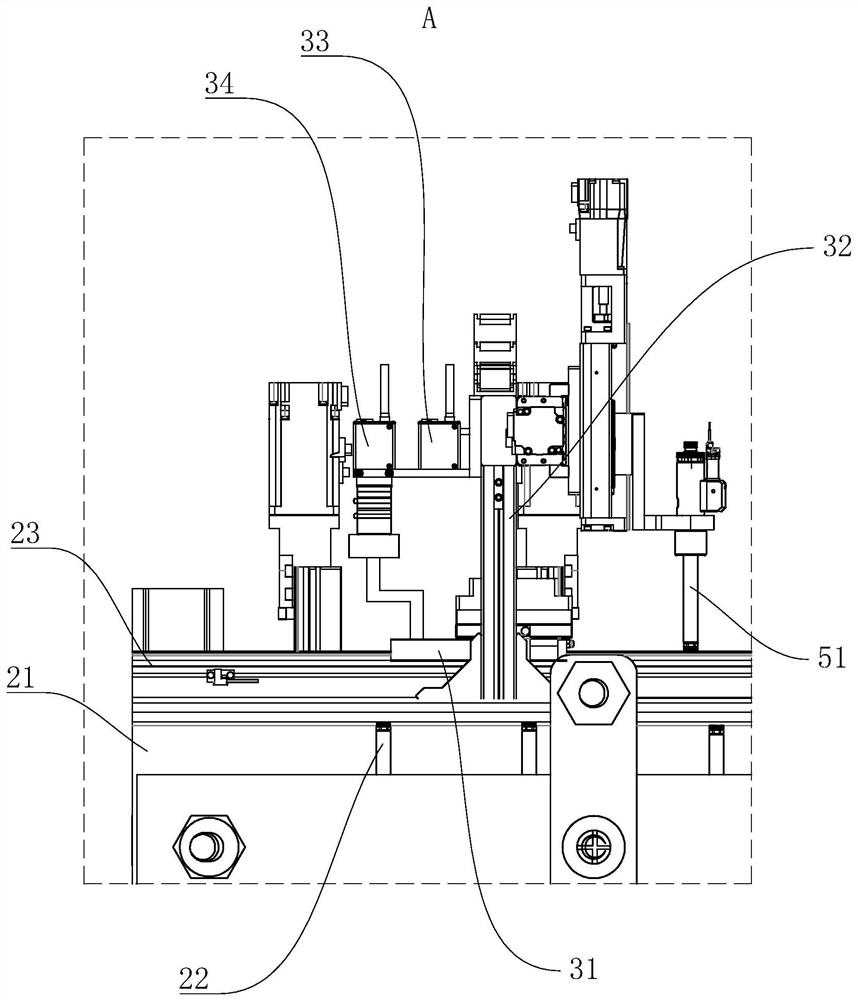

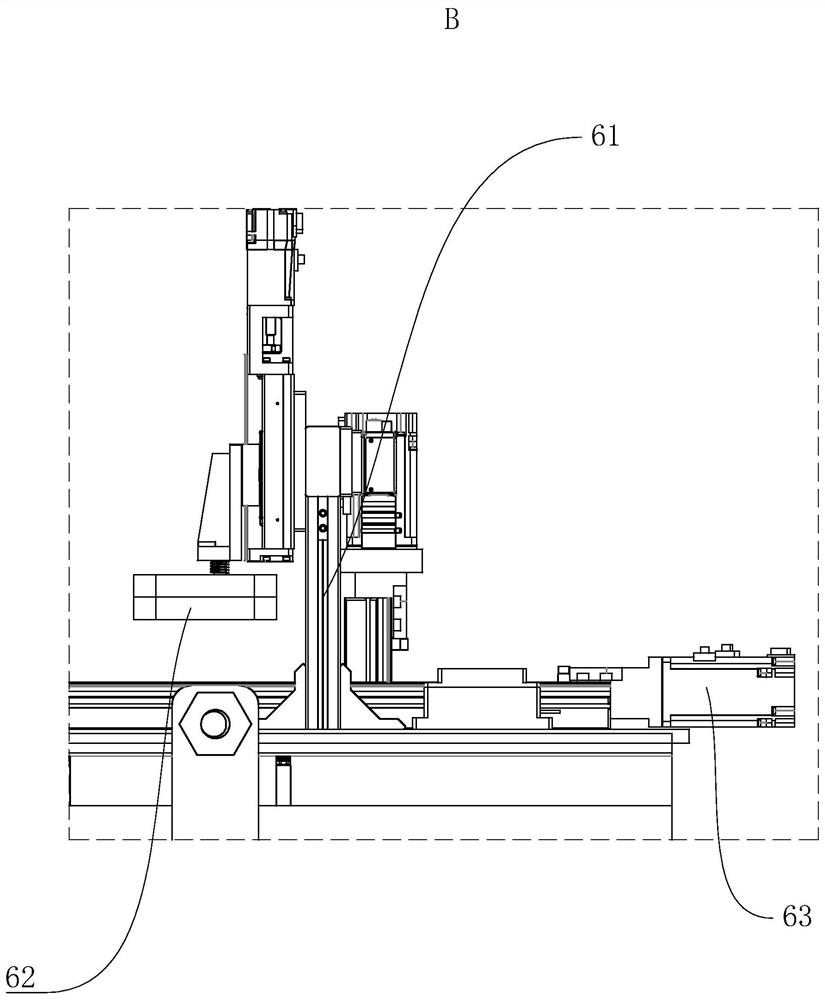

[0023] Reference attached figure 1 to attach Image 6 , a transformer, including a transformer body 11, the upper end of the transformer body 11 is provided with a dynamic cooling device;

[0024] The dynamic heat dissipation device includes a base 21 as a load-bearing structure, the base 21 is made of heat-dissipating material, and the base 21 is fixedly arranged on the upper end of the transformer body 11, and a plurality of temperature sensors 22 are regularly arranged on the side of the base 21 , the temperature sensors 22 are arranged at intervals to obtain the local real-time temperature value of the base 21 .

[0025] Two guide rails 23 are fixed horizontally on the upper end of the base 21, and a cooling water assembly is arranged on the two guide rails 23. The cooling water assembly includes a heat conducting seat 31, and the heat conducting seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com