Power battery sealing nail welding detection device and method

A welding detection and power battery technology, applied in the direction of measuring devices, electrical components, optical testing defects/defects, etc., to achieve the effect of improving accuracy, improving product quality consistency, and reducing manual re-inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

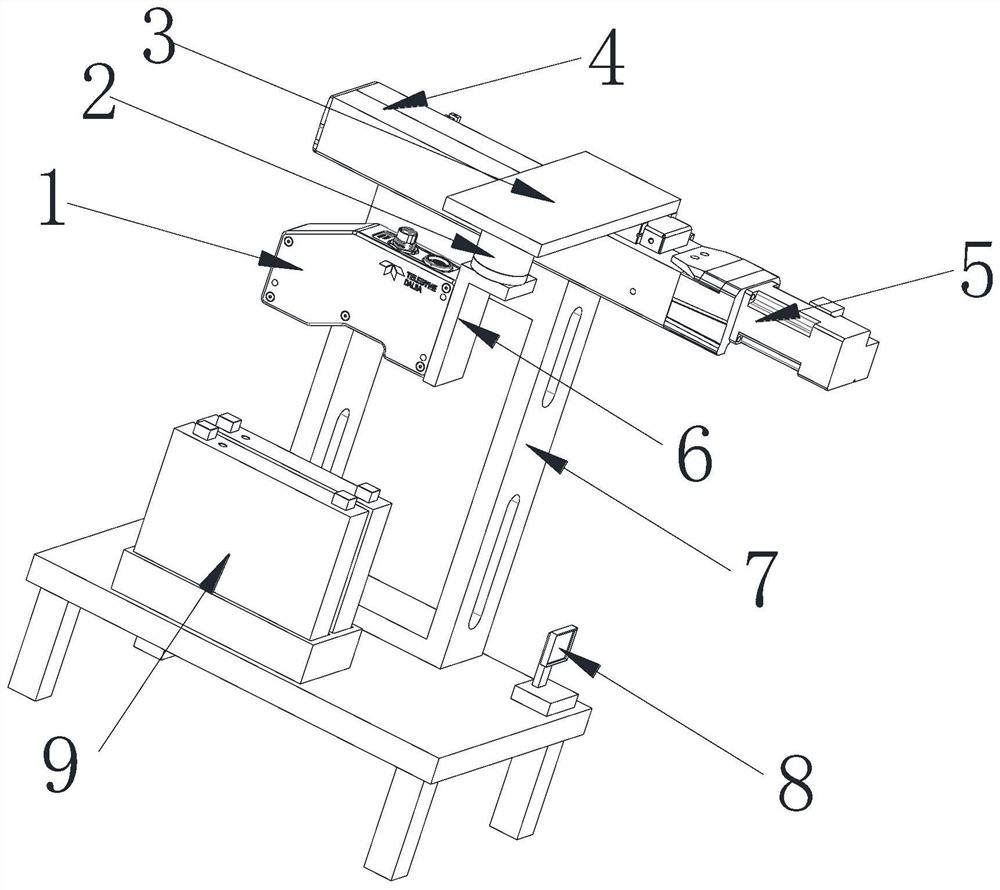

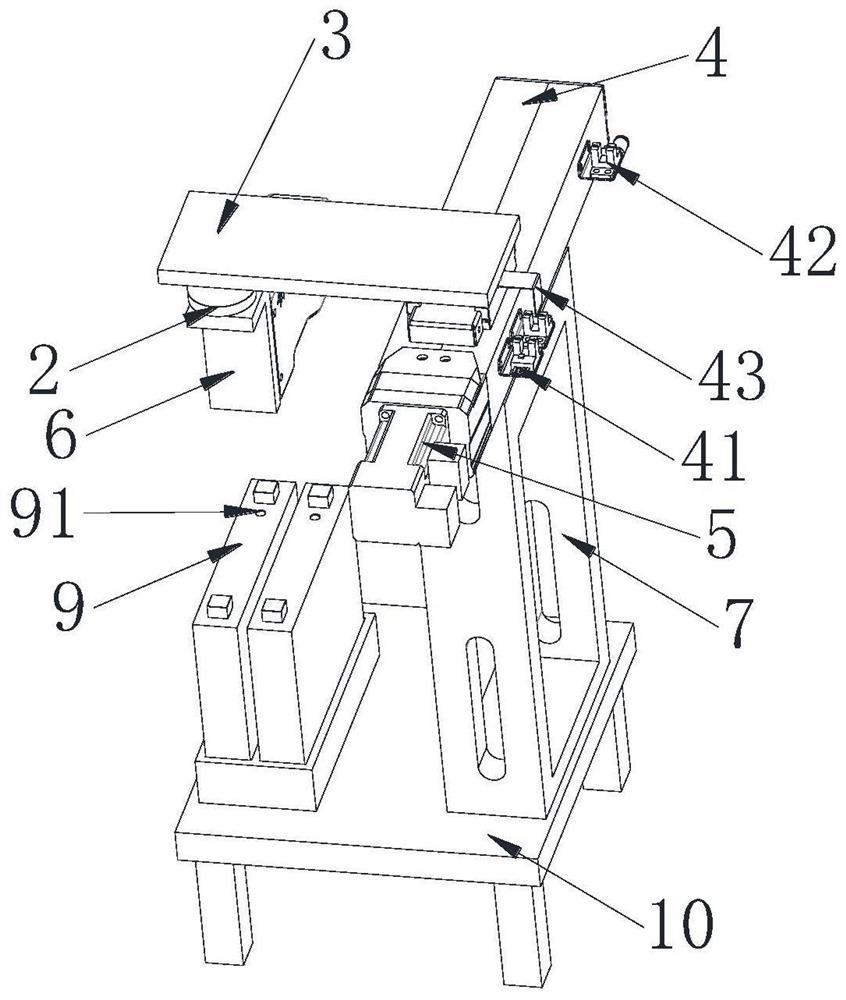

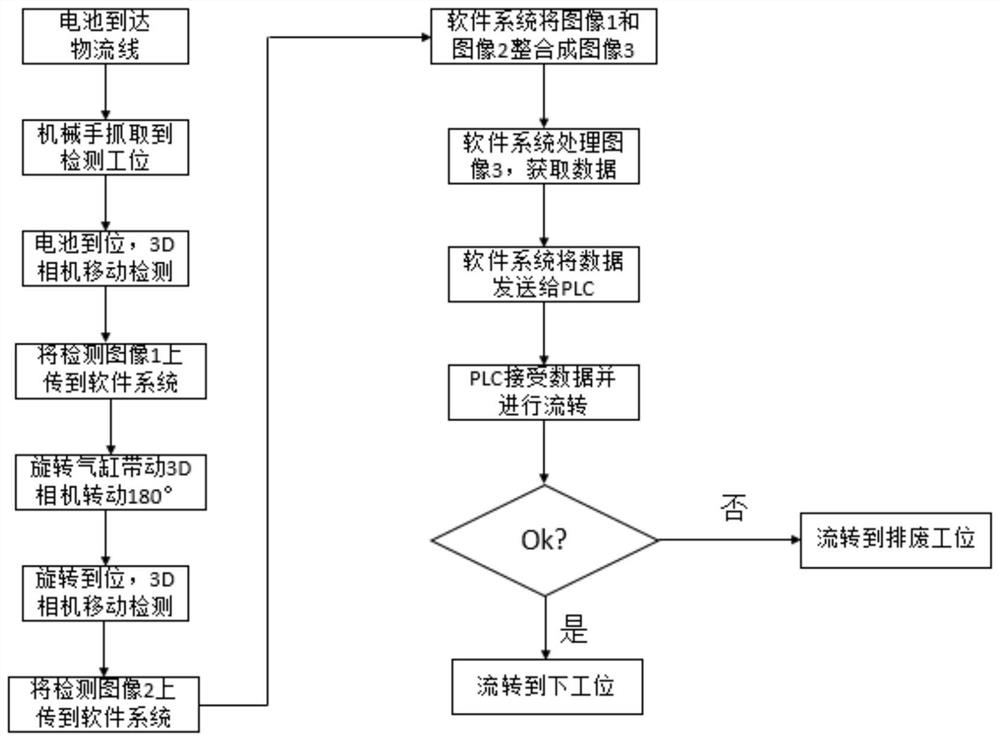

[0024] Such as Figure 1-2 As shown, a power battery sealing nail welding detection device includes an image acquisition part and an image processing part, and the image acquisition part includes a 3D camera 1, a motion assembly that drives the 3D camera 1 to rotate and move, a support frame 7, and a base 10, The support frame 7 is used to support the motion assembly, the support frame 7 and the battery 9 used for detection are fixed on the base 10, and the 3D camera 1 scans the battery 9 to be detected multiple times under the action of the motion assembly, Realize welding bead defect detection. The image processing part is connected to the data terminal of the 3D camera 1 for processing the scanned image.

[0025] Specifically, the moving assembly includes a rotating unit and a horizontal moving unit, the rotating unit includes a rotating cylinder 2 fixed on the transition plate 3, and the rotating cylinder 2 drives the camera to rotate. Optimally, the 3D camera 1 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com