Method for representing adsorption and desorption processes of corrosion inhibitor

A corrosion inhibitor, adsorption and desorption technology, applied in the field of characterization of the corrosion inhibitor adsorption and desorption process, can solve the problem that the quantitative analysis of the corrosion inhibitor has not yet been realized, and achieve the effect of improving the accuracy of the model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Dissolving 8-hydroxyquinoline (8-HQ) molecules in 3.5 wt% NaCl solution, the concentration of 8-HQ is 0.1 g / L.

[0023] 2. Put 6 pieces of 1×1×0.3cm 3 The Q235 carbon steel samples were soaked in the above corrosion inhibitor solution for 3h, 15h, 30h, 45h, and 60h respectively. After soaking, the Q235 samples were taken out and dried.

[0024] 3. Deposit 10nm copper nanoparticles on the surface of the Q235 sample adsorbed with 8-HQ.

[0025] 4. Use a 785nm laser Raman spectrometer to detect the corrosion inhibitor signal on the surface of the sample.

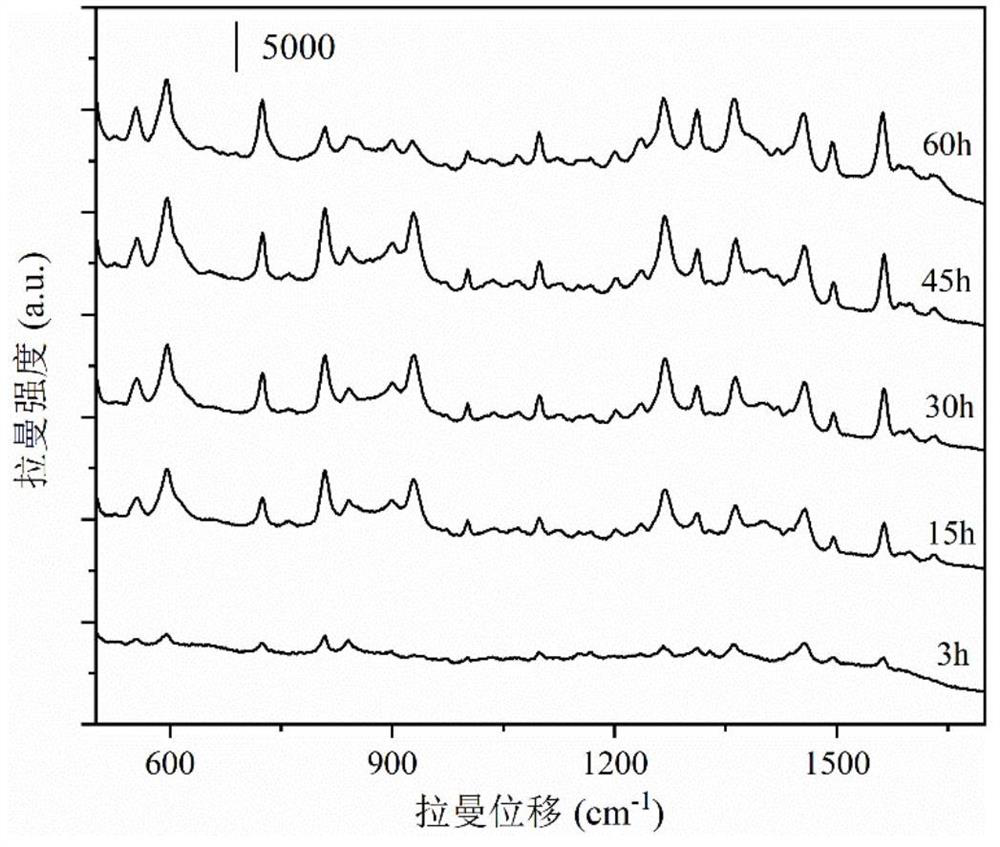

[0026] figure 1 It is the enhanced Raman spectrum signal measured after the 8-HQ molecule is adsorbed on the surface of Q235 carbon steel in Example 1. As the immersion time increases, the Raman spectrum signal of the corrosion inhibitor gradually increases, indicating that the adsorption amount of the corrosion inhibitor on the carbon steel surface gradually increases, and reaches saturation at 60 h, thus obtainin...

Embodiment 2

[0028] 1. Different masses of 2-mercaptobenzothiazole (MBT) molecules were dissolved in 3.5wt% NaCl solution, and the concentrations of MBT were 0.1g / L, 0.2g / L, 0.3g / L, 0.4g / L respectively.

[0029] 2. Place 1×1×0.2cm 3 The AA2024-T3 aluminum alloy was soaked in the above-mentioned corrosion inhibitor solution for 2h-92h. After different soaking times, the aluminum alloy samples were taken out and dried.

[0030] 3. Depositing 10nm gold nanoparticles on the surface of the aluminum alloy sample adsorbed with MBT.

[0031] 4. Use a 532nm laser Raman spectrometer to detect the enhanced Raman spectrum signal of MBT molecules on the surface of the sample after soaking for different times, and obtain a saturated adsorption spectrum.

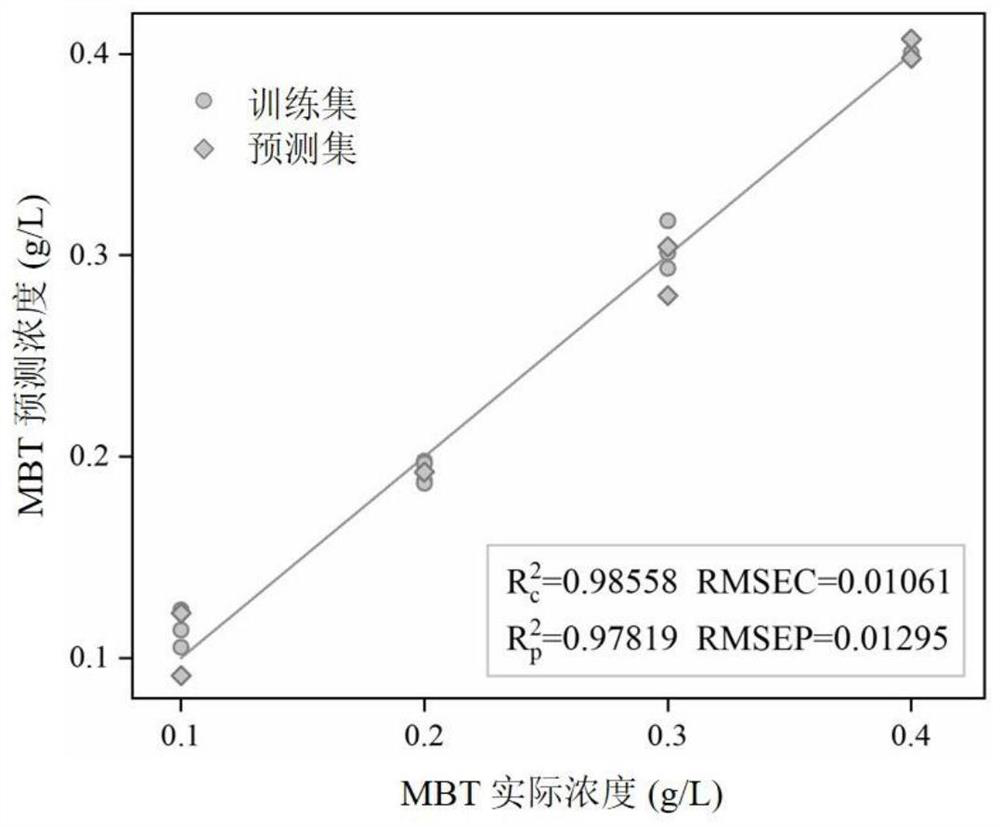

[0032] 5. Extract saturated adsorption Raman spectra of different concentrations of corrosion inhibitors, 5 pieces of spectral data for each concentration, group all spectral data, including training set and prediction set, the training set accounts f...

Embodiment 3

[0036] 1. Different masses of 2-mercaptobenzothiazole (MBT) molecules were dissolved in 3.5wt% NaCl solution, and the concentrations of MBT were 0.1g / L, 0.2g / L, 0.3g / L, 0.4g / L respectively.

[0037] 2. Place 1×1×0.2cm 3 The AA2024-T3 aluminum alloy was soaked in the above-mentioned corrosion inhibitor solution for 2h-92h. After different soaking times, the aluminum alloy samples were taken out and dried.

[0038] 3. Depositing 5nm silver nanoparticles on the surface of the aluminum alloy sample adsorbed with MBT.

[0039] 4. Use a 785nm laser Raman spectrometer to detect the enhanced Raman spectrum signal of MBT molecules on the surface of the sample after soaking for different times, and obtain a saturated adsorption spectrum.

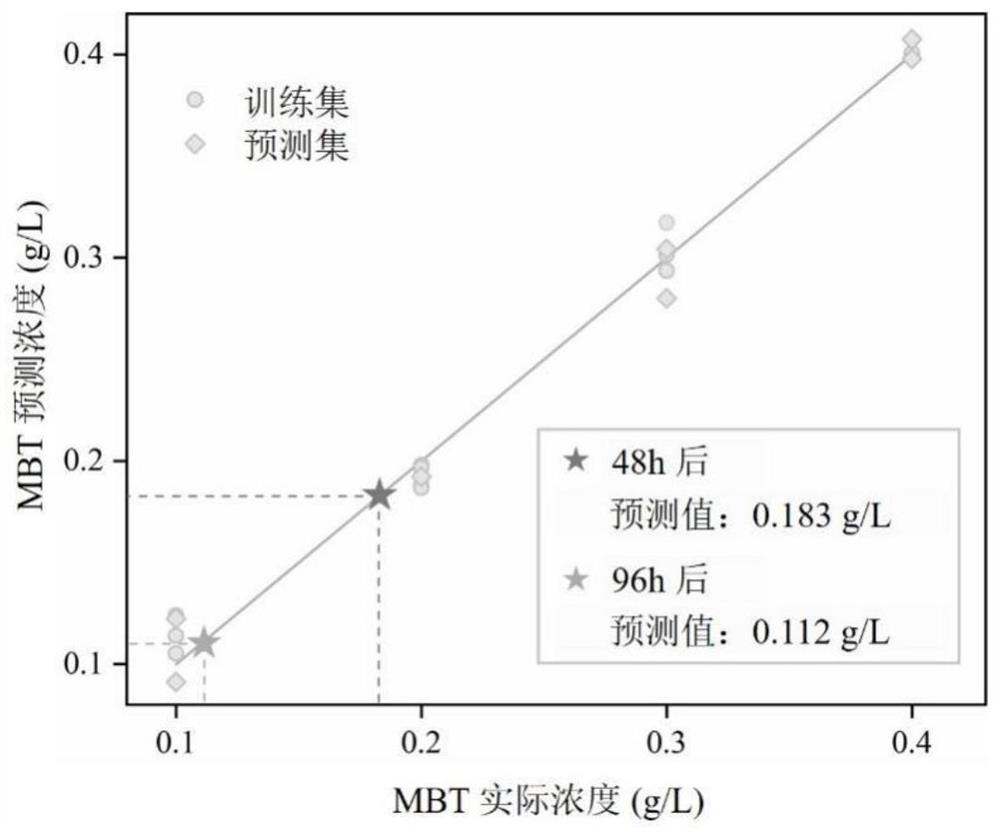

[0040] 5. Extract saturated adsorption Raman spectra of different concentrations of corrosion inhibitors, 5 pieces of spectral data for each concentration, group all spectral data, including training set and prediction set, the training set accounts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com