Injection mold for instrument panel

A technology for injection molds and dashboards, which can be used in household appliances, other household appliances, applications, etc. It can solve the problems of difficult product removal and direct removal of reinforcement ribs, etc., to achieve independent adjustment control, reduce the difficulty of removal, and simplify The effect of mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

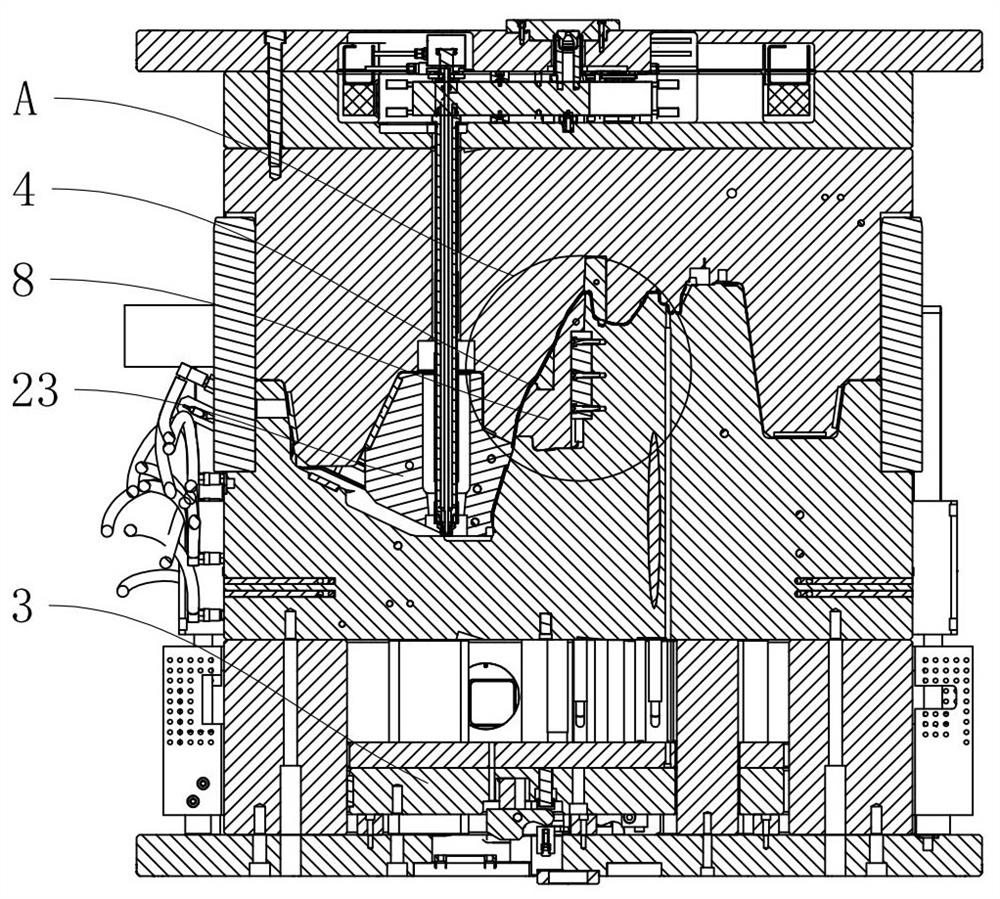

[0051] The following is attached Figure 1-15 The application is described in further detail.

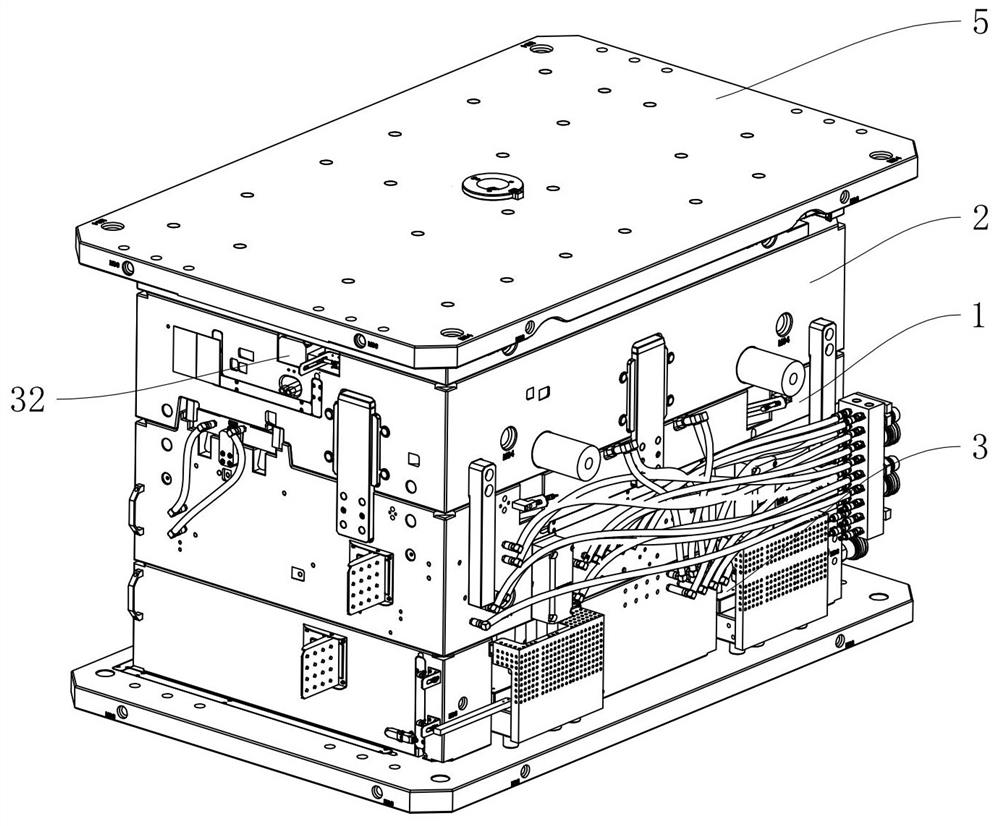

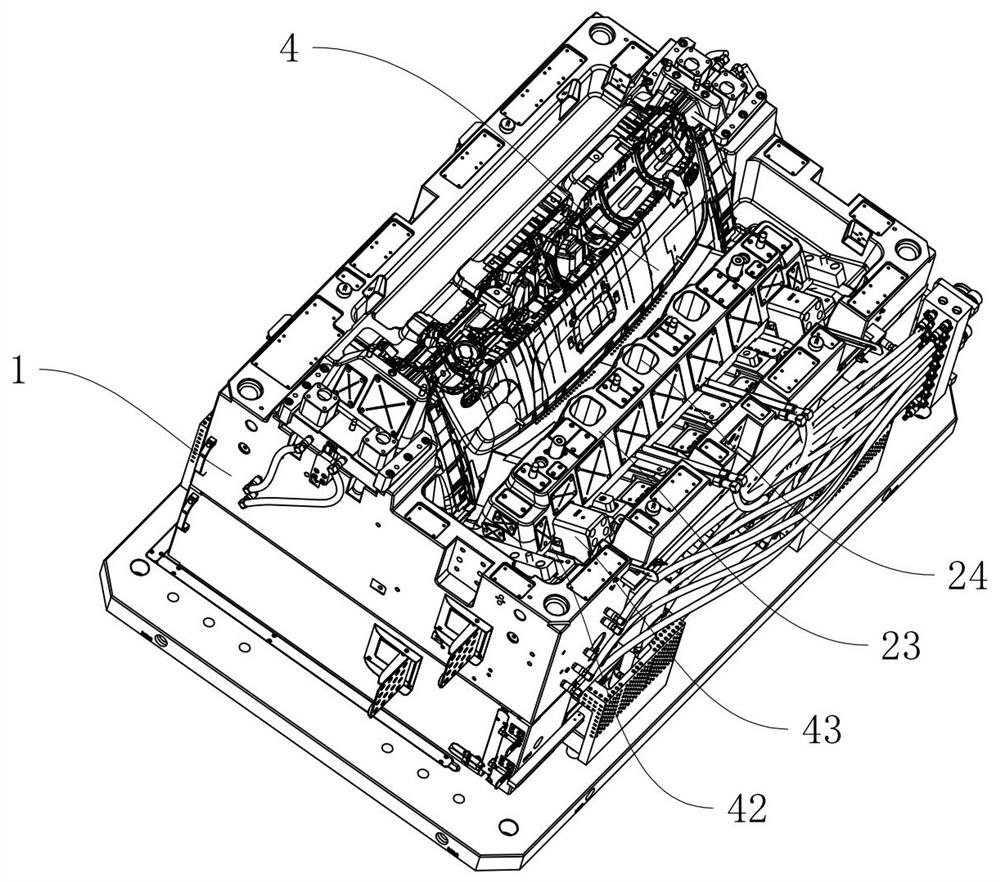

[0052] The embodiment of the present application discloses an injection mold for an instrument panel. refer to figure 1 and figure 2 , the injection mold for the instrument panel includes a plastic injection assembly 5 , a cavity plate 2 , a core plate 1 , and an ejection assembly 3 from top to bottom. Among them, a cavity 4 for forming an instrument panel is formed between the cavity plate 2 and the core plate 1, and the ejector assembly 3 is provided with a part of the panel for forming the instrument panel and for pushing the instrument panel out of the cavity 4. The straight top block 8 is provided with a forming slider 23 for forming part of the instrument panel on the core plate 1, and a core-pulling slider 32 for forming the through hole shape in the instrument panel is provided on the cavity plate 2.

[0053] Referring to Fig. 3, two push cylinders 42 are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com