Material feeding device

A material and material box technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency and difficulty in picking up materials, and achieve the effect of improving work efficiency, reducing the difficulty of picking, and picking up quickly and accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

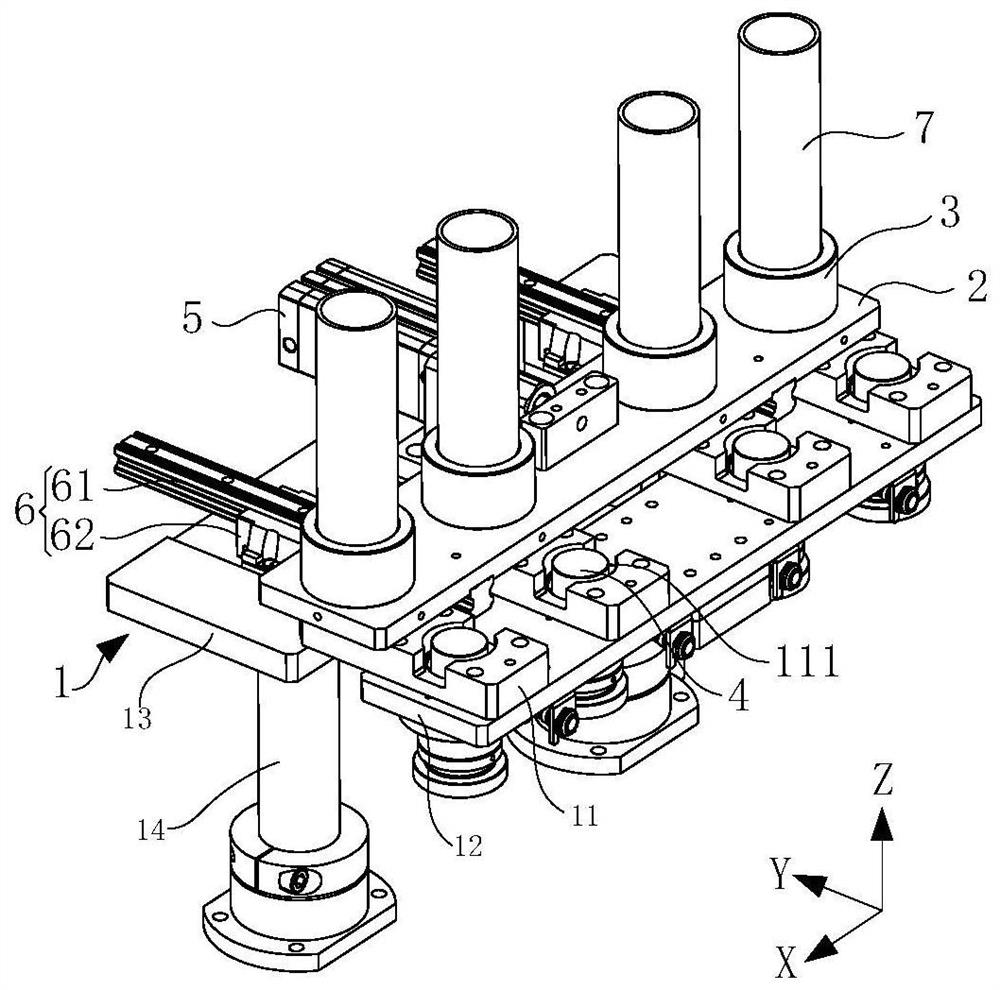

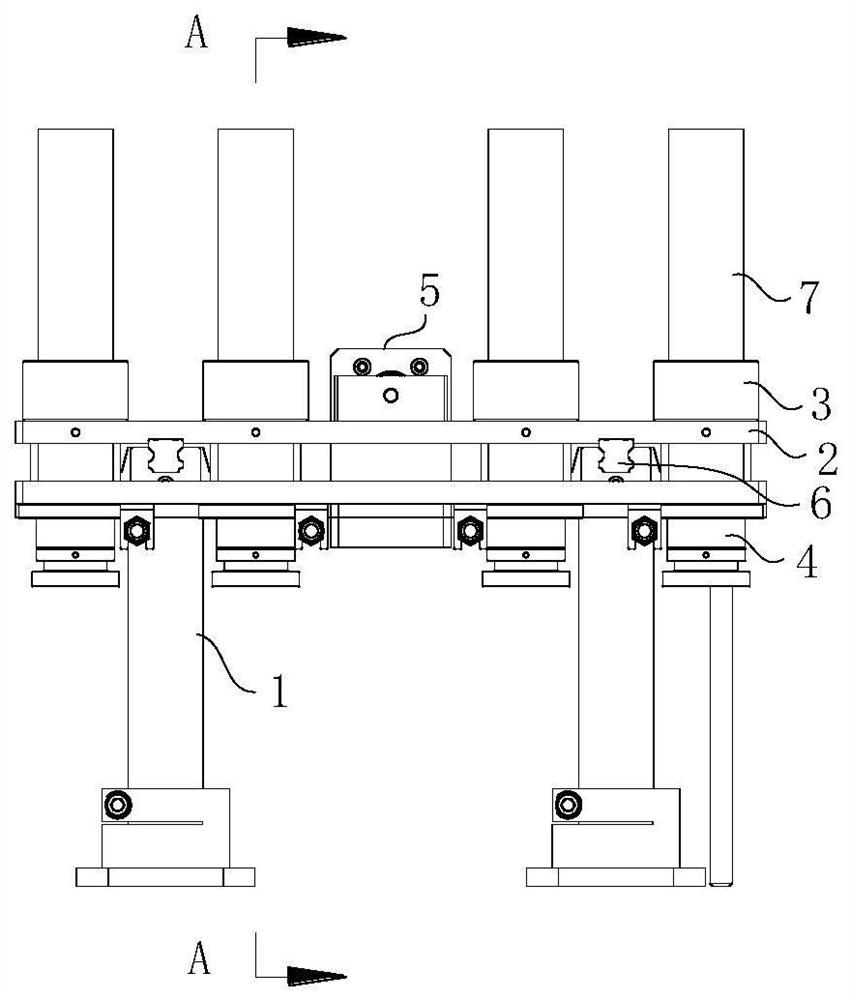

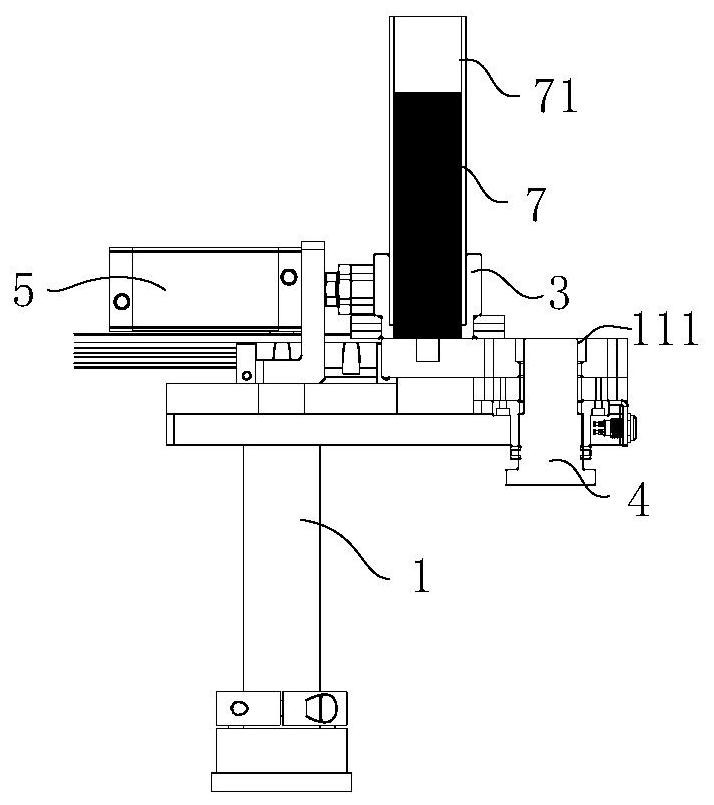

[0032] In order to make the technical solutions and advantages in the embodiments of the present application clearer, the exemplary embodiments of the present application will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present application, and Not an exhaustive list of all embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0033] At present, in the assembly process of railway vehicles, due to the small or thin sheet materials, it is difficult to manually pick up the required amount of materials, and the efficiency is low. In the related art, in order to facilitate workers to pick up, materials are usually placed in tooling with material slots, the materials are distributed in a matrix in the tooling, and there is a certain distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com