Efficient shading glass curtain new material

A glass curtain wall and new material technology, applied in metal processing and other directions, can solve problems such as pollution and affecting use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

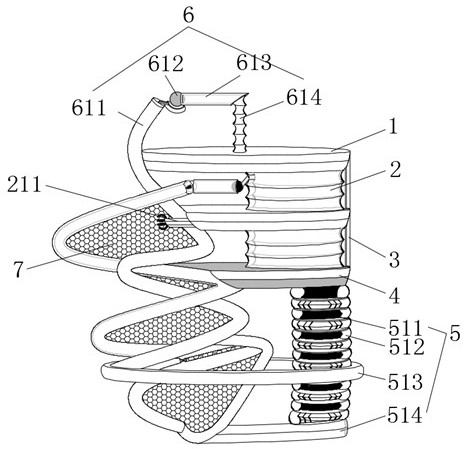

[0034] see figure 1 and Figure 4 , a cutting device for an efficient light-shielding glass curtain wall, comprising a movable plate 1, a half-circle plate 101 is arranged on the side of the movable plate 1, an elastic ring 102 is connected through the inside of the movable plate 1, and the bottom side wall of the movable plate 1 A rotating mechanism 2 is connected through it, and the inside of the rotating mechanism 2 includes a connecting pipe 211, the inner end of the connecting pipe 211 is connected with a sliding ring 215, the side wall of the sliding ring 215 is connected with a bracket 214, and the side wall of the sliding ring 215 is A support pipe 212 is connected through it, and a ball 213 is connected through the end of the support pipe 212 far away from the bracket 214. A support rod 3 is connected through the side of the movable plate 1, and a base plate 4 is connected through the bottom end of the support rod 3. The base plate The bottom of 4 is connected with s...

Embodiment 2

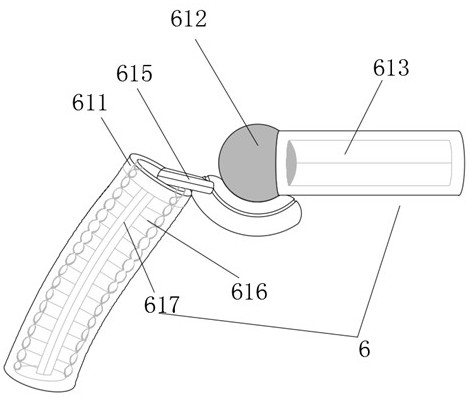

[0039] see Figure 1-2 , a cutting device for an efficient light-shielding glass curtain wall, comprising a movable plate 1, a half-circle plate 101 is arranged on the side of the movable plate 1, an elastic ring 102 is connected through the inside of the movable plate 1, and the bottom side wall of the movable plate 1 A rotation mechanism 2 is connected through it, a support rod 3 is connected through the side of the movable plate 1, a base plate 4 is connected through the bottom end of the support rod 3, and a spring pressing mechanism 5 is connected through the bottom of the base plate 4. The twitching mechanism 6 is connected through the top side wall, and the inside of the twitching mechanism 6 includes an elastic tube 611. The inner axis of the elastic tube 611 is connected with a central column 617, and the side wall of the central column 617 is connected with a needle bar 616. The top of the central column 617 is connected with a connecting column 615, the right end of...

Embodiment 3

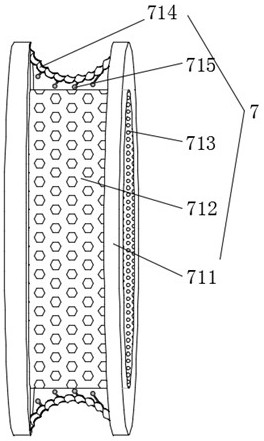

[0044] see figure 1 and image 3 , a cutting device for an efficient light-shielding glass curtain wall, comprising a movable plate 1, a half-circle plate 101 is arranged on the side of the movable plate 1, an elastic ring 102 is connected through the inside of the movable plate 1, and the bottom side wall of the movable plate 1 A rotating mechanism 2 is connected through it, a support rod 3 is connected through the side of the movable plate 1, a base plate 4 is connected through the bottom end of the support rod 3, and a spring pressing mechanism 5 is connected through the bottom of the base plate 4. The interior includes a support block 511, the side wall of the support block 511 is connected with an air bag 512, the outer wall of the support block 511 is connected with a movable ring 513, the bottom end of the support block 511 is connected with a connecting rod 514, and the movable plate 1 The twitching mechanism 6 is connected through the top side wall, and the inside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com