Ore screening and cleaning device

A cleaning device and ore technology, which is applied in the direction of filter screen, cleaning method and equipment, cleaning method using liquid, etc., can solve the problems of increasing ore operation process, single function, ore washing equipment difficult to wash ore and beneficiation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

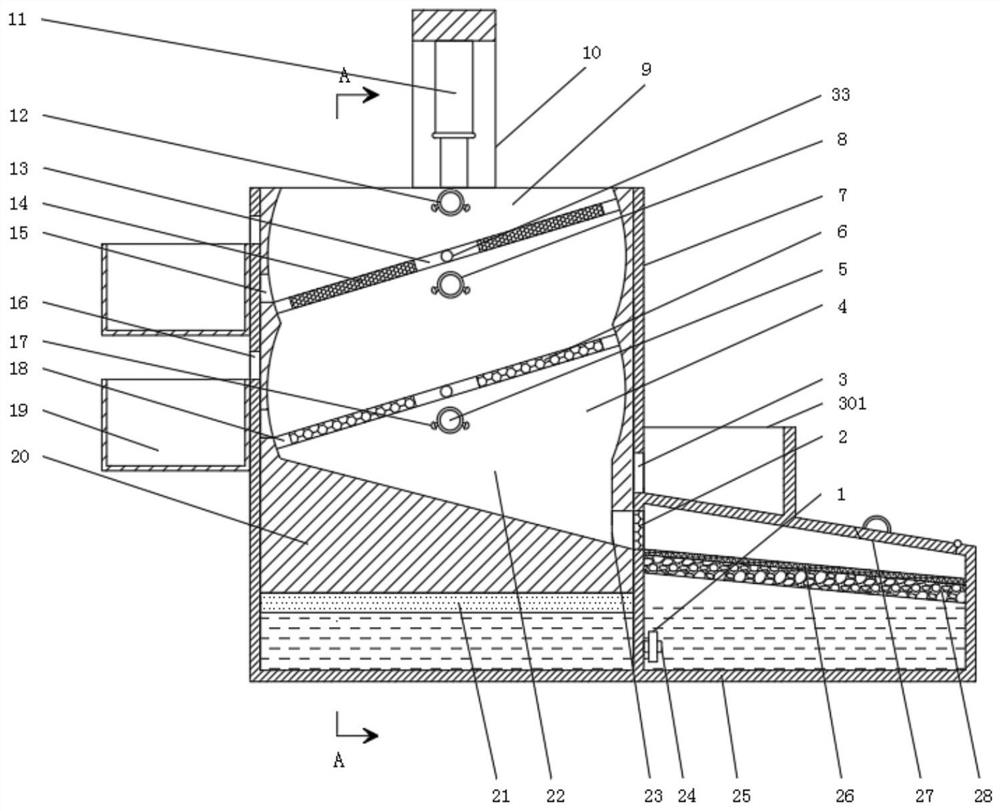

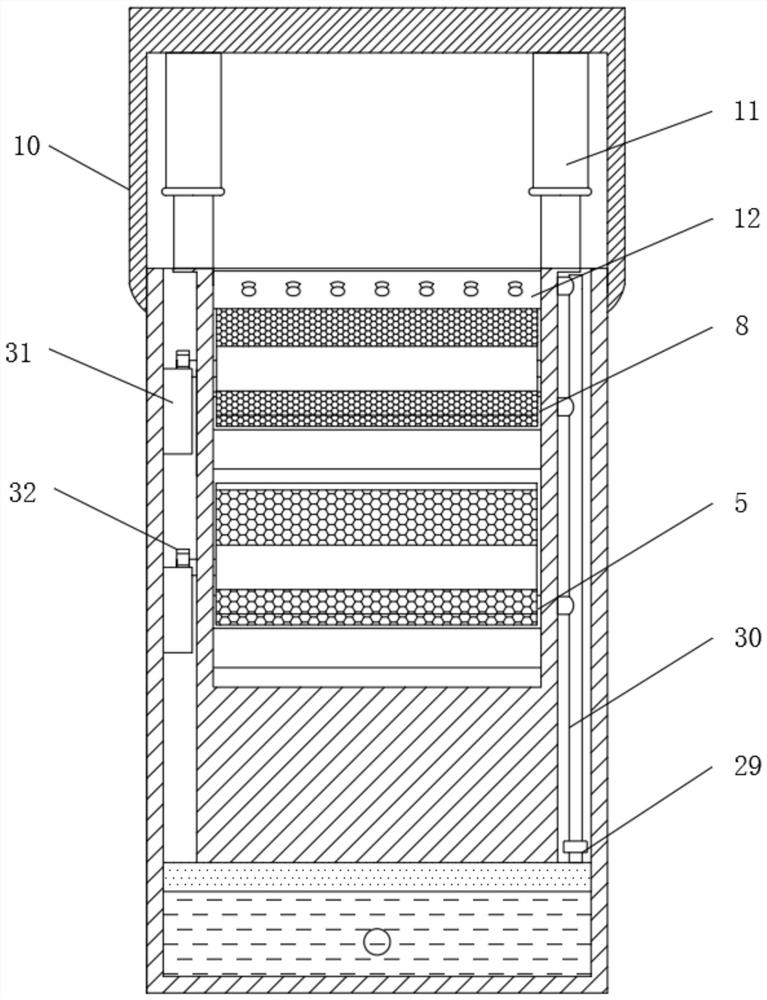

[0025] Such as Figure 1-2 A kind of ore screening and cleaning device shown includes a main unit, a screening and cleaning unit and a drive unit. The main unit includes a square housing 7, a piston 21, a water storage tank 25, a filter screen 26 and an active carbon layer 28, and the piston 21 is slidably arranged on the Inside the square housing 7 , the water storage tank 25 is arranged on one side of the square housing 7 , and one side of the top of the water storage tank 25 is hinged with a cover 27 , between the top of the water storage tank 25 and the square housing 7 A grid net 2 is provided, and a filter screen 26 and an activated carbon layer 28 are respectively arranged from top to bottom inside the water storage tank 25 below the grid net 2;

[0026]Screening and cleaning unit comprises containing housing 20, screening parts and cleaning parts, and containing housing 20 is arranged on the middle position of piston 21 tops, and the length of containing housing 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com