FCM packaging chip machine manufacturing method, packaging chip machine and camera module product

A production method and a technology of encapsulating chips, which are applied in image communication, radiation control devices, televisions, etc., can solve problems such as difficult production process control, high product costs, and decreased product reliability, so as to reduce equipment investment costs and The effect of labor cost, high market competitive advantage, and product yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

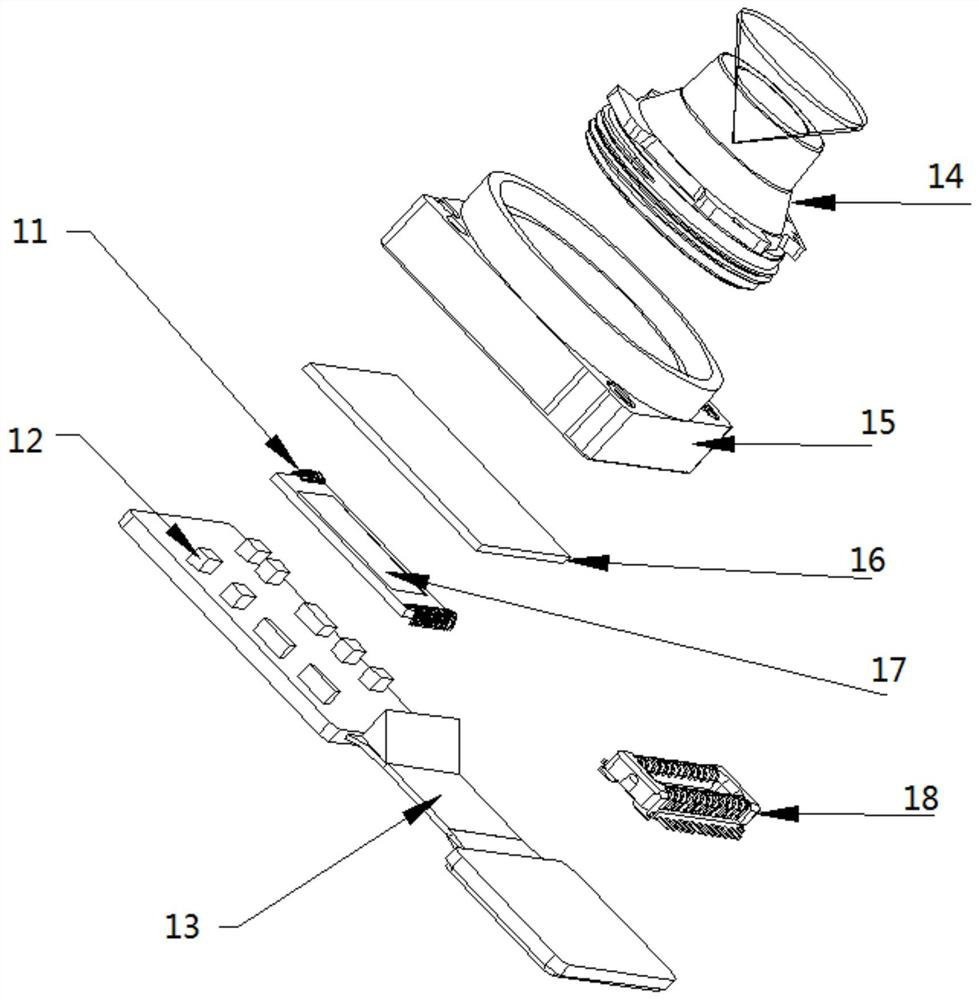

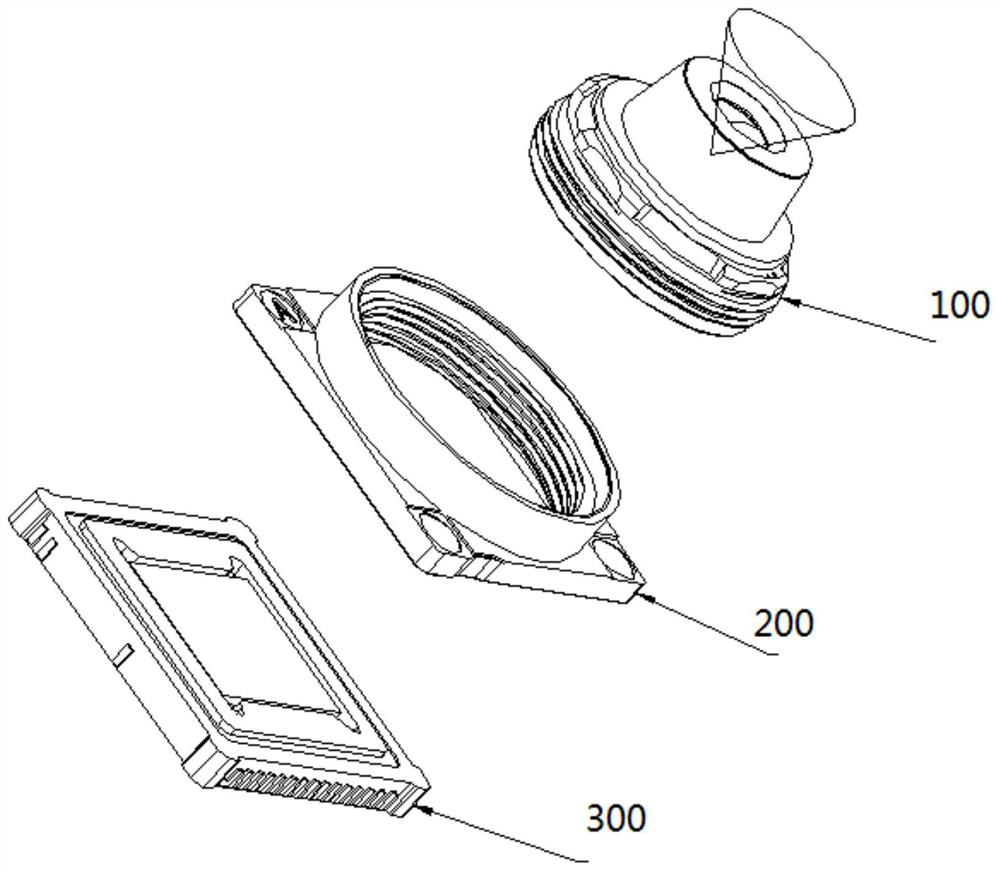

specific Embodiment approach 1

[0073] FCM production process: see Figure 10 ;

[0074] Step 1: Die the copper foil with a knife die and bend it into a circuit;

[0075] Step 2: use spot plating process (spot plating process: one of the electroplating processes, which can electroplate the designated position) to plate the circuit with nickel and gold;

[0076] Step 3: Injection molding through the inster molding process (the inster molding process is the insert molding process: a molding method in which the metal is embedded in a pre-fabricated mold cavity, and then the molten plastic material is injected); in this step, the step In 2, the nickel and gold-plated circuits are embedded in the prefabricated mold cavity, and then the molten plastic material is injected for injection molding;

[0077] Step 4: After molding, inject solder paste, attach capacitors, resistors and other electronic components, and fix them by reflow soldering;

[0078] Step 5: Then turn over and paint the adhesive filter, bake and...

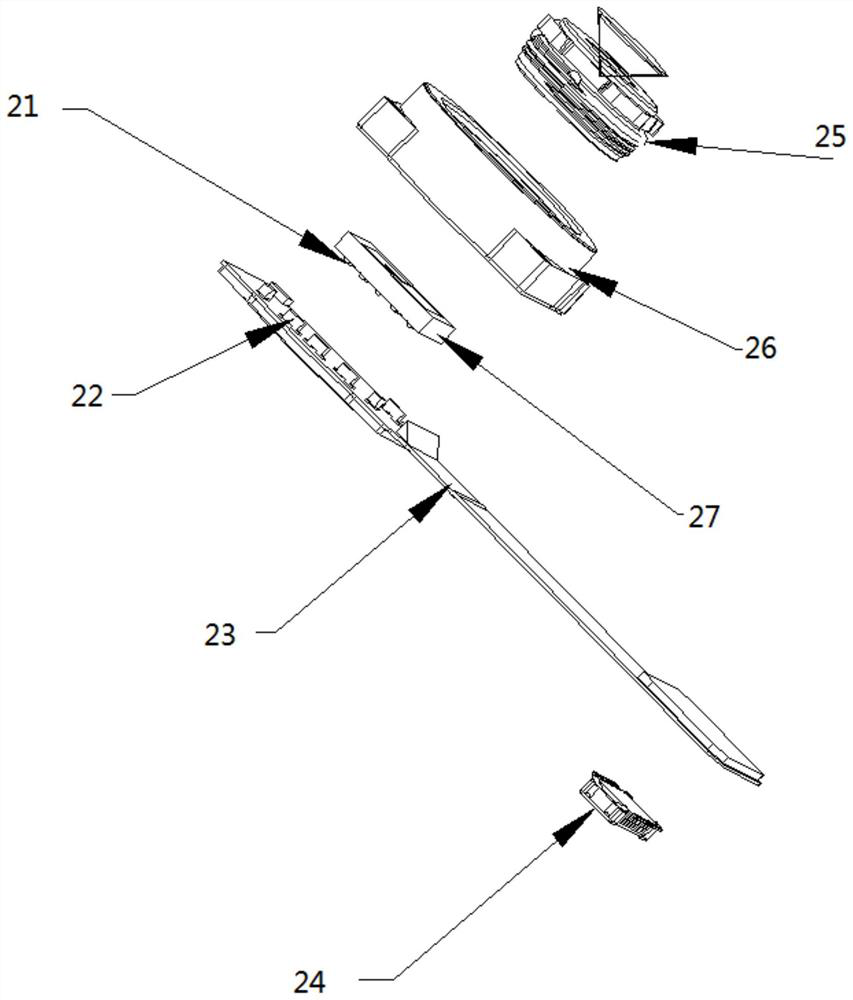

specific Embodiment approach 2

[0082] Such as Figure 7 , another production process of FCM: see Figure 11 ;

[0083] Step 1: Die the copper foil with a knife die and bend it into a circuit;

[0084] Step 2: use spot plating process (spot plating process: one of the electroplating processes, which can electroplate the designated position) to plate the circuit with nickel and gold;

[0085] Step 3: Injection molding by inster molding process (inster molding process: a molding method in which metal is embedded in a prefabricated mold cavity, and then molten plastic material is injected); in this step, nickel is plated in step 2 Embed the circuit with gold into the prefabricated mold cavity, and then inject the molten plastic material into injection molding;

[0086] Step 4: Inject solder paste after molding, and paste electronic components such as capacitors and resistors;

[0087] Step 5: Simultaneously weld the chip with a laser solder ball welding machine to solder solder balls;

[0088] Step 6: Conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com