Pulverized coal boiler and grate furnace combined waste incineration power generation system and method

A pulverized coal boiler and waste incineration technology is applied in the field of waste incineration power generation system to achieve the effects of reducing primary air rate, improving utilization rate and reducing flue gas treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are to explain rather than limit the present invention.

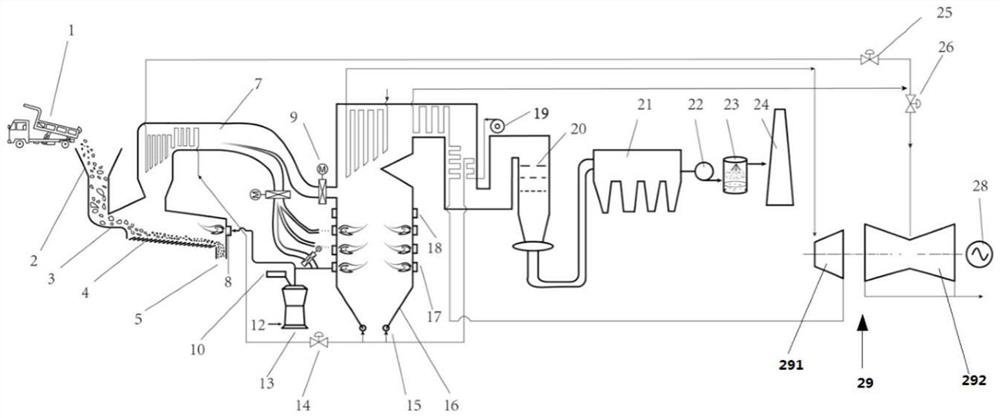

[0031] The present invention is a waste incineration power generation system combined with a pulverized coal boiler and a grate furnace, such as figure 1 As shown, it includes a grate furnace 3, a pulverized coal boiler 16 and a steam turbine 29; the tail flue 7 of the grate furnace 3 is provided with a main pipe, and the main pipe is connected to the burn-off air nozzle 18 in the furnace of the pulverized coal boiler 16 above;

[0032] The pulverized coal boiler 16 includes a front-end superheater arranged above the furnace, and a rear-end superheater arranged in the horizontal flue, wherein the flue gas of the pulverized-coal boiler 16 first passes through the front-end superheater to release heat, and then passes through the rear-end superheater to release heat. Therefore, the temperature of the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com