A high-efficiency beating device for packaging cardboard regeneration

A high-efficiency technology for packaging cardboard, applied in pulp beating methods, papermaking, paper recycling, etc., can solve problems such as shortening the service life of blades, achieve the effects of accelerating soaking speed, avoiding a large amount of accumulation, and increasing structural strength

Active Publication Date: 2022-05-31

江苏京环隆亨纸业有限公司

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The recycling of packaging cardboard requires crushing and beating first, and then further processing of the stirred pulp. When the cardboard is just put into the beater, it takes a certain time for the cardboard to absorb water, and a large amount of cardboard will be stacked and floated on the water surface of the beater , workers need to wait for this batch of cardboard to be completely dissolved, or use tools to completely press the cardboard into the water before feeding the next batch; in addition, in order to improve the crushing efficiency, the beater will have many sharp rotating blades inside, but it has just been The paper thrown into the water has not yet dissolved and its texture is relatively hard. The blade of the rotating blade will continuously collide with the undissolved cardboard and cut it, which will obviously shorten the service life of the blade.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

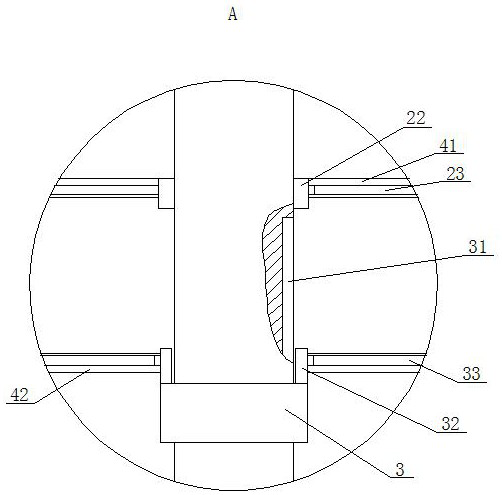

[0016] Further, as shown in FIG. 1 , the motor 21 described in this embodiment is a forward and reverse rotation motor. Use forward and reverse motor

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

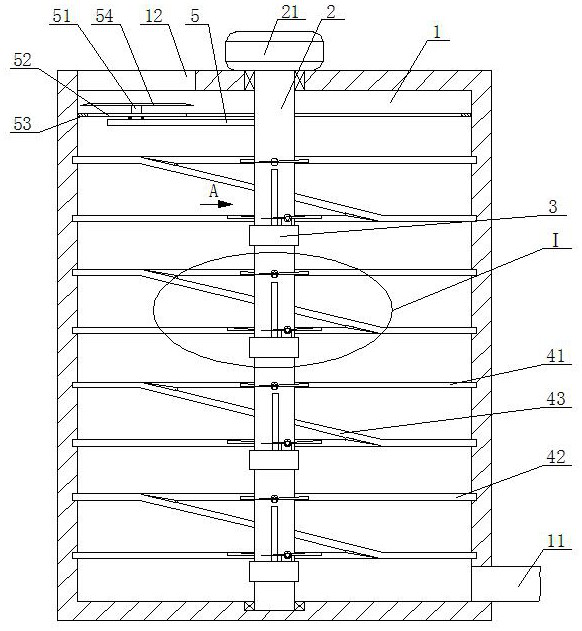

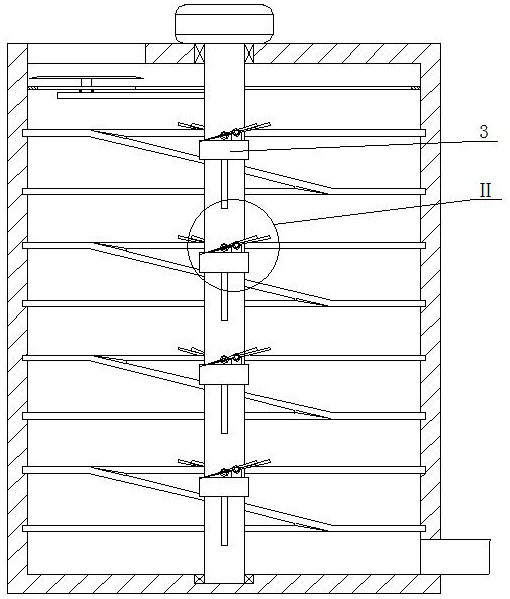

A high-efficiency beating device for packaging cardboard regeneration, including a closed tank body, a coaxial main shaft is installed for rotation inside the tank body, a motor is fixedly installed on the top surface of the tank body, the output shaft of the motor is fixedly connected with the upper end of the main shaft, and the two sides of the outer circumference of the main shaft The torsion springs are respectively connected with several first rotating shafts, and each first rotating shaft is fixedly connected with a first blade, and several sliding sleeves are set on the outer periphery of the main shaft, and the sliding sleeves can only slide vertically on the outer periphery of the main shaft. The sides are respectively fixedly installed with a second rotating shaft. The invention only needs to change the running direction of the motor to freely switch between the feeding state and the beating state. On the one hand, it speeds up the soaking speed of the cardboard in the feeding stage and avoids a large amount of cardboards accumulating on the water surface. The division of labor prolongs the service life of the rotary blade, and is suitable for promotion as a new type of beater for cardboard recycling.

Description

A high-efficiency beating device for packaging cardboard regeneration technical field The invention belongs to the field of packaging paperboard recycling, specifically a kind of packaging paperboard recycling high-efficiency beating pack set. Background technique Recycling of packaging cardboard is that firstly need to be pulverized and beaten, and then the stirred pulp is further processed. Step processing, when the cardboard is just put into the beater, since it takes a certain time for the cardboard to absorb moisture, a large amount of cardboard will be stacked and floated. Floating on the water surface of the beater, workers need to wait for the batch of cardboard to be completely dissolved, or use a tool to completely press the cardboard into the water before The next batch of materials can be fed; in addition, in order to improve the crushing efficiency, the beater will have many sharp rotating blades inside. However, the paper that has just been put into t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D21B1/32D21B1/34D21D1/02

CPCD21B1/32D21B1/345D21D1/02Y02W30/64

Inventor 乔明辉周皓宸顾亚明

Owner 江苏京环隆亨纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com