Scaffold steel pipe repairing and maintaining device

A technology for scaffolding and steel pipes, which is applied in the field of repair and maintenance devices for scaffolding steel pipes, can solve problems such as inability to straighten steel pipes, affect subsequent use of steel pipes, and low efficiency of rust removal of steel pipes, so as to improve the efficiency and quality of rust removal and improve drying efficiency and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

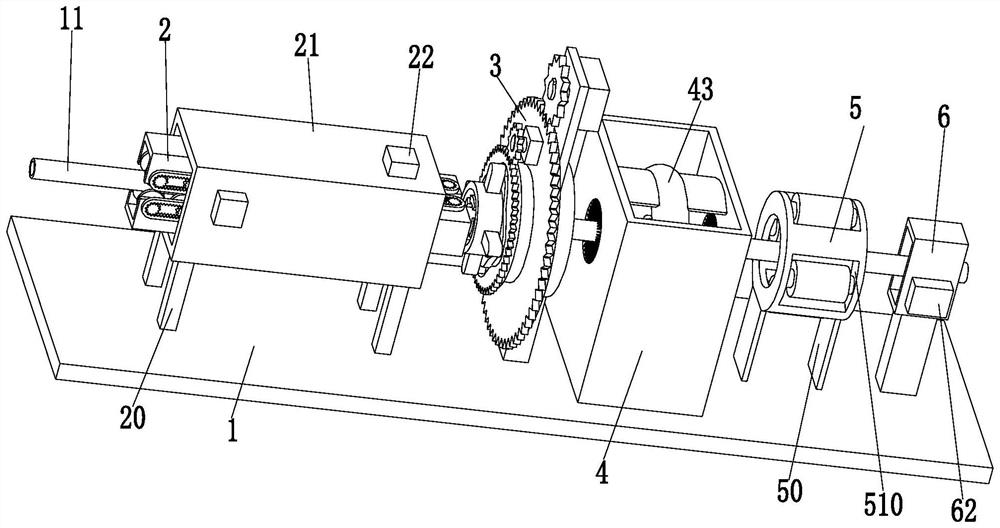

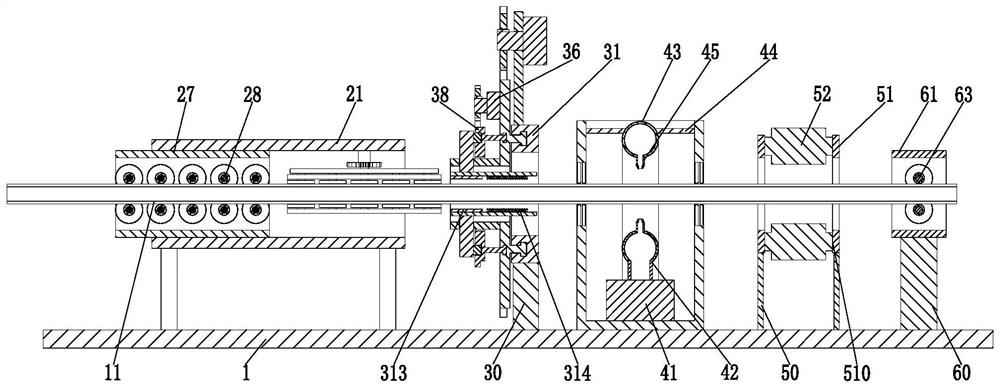

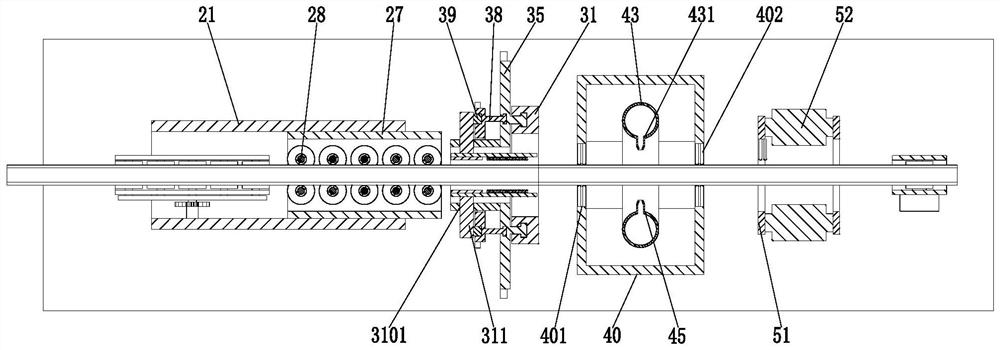

[0030] refer to figure 1 , figure 2 and image 3 , a scaffolding steel pipe repair and maintenance device, including a base plate 1, a straightening mechanism 2, a derusting mechanism 3, a painting mechanism 4, a drying mechanism 5 and a discharge mechanism 6, and the bottom plate 1 is sequentially installed with adjusters from the left end to the right end. Straightening mechanism 2, derusting mechanism 3, painting mechanism 4, drying mechanism 5 and discharging mechanism 6.

[0031] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 9 , the straightening mechanism 2 includes a support rod 20, a square frame 21, a motor 22, a positioning round rod 23, a driving gear 24, a transmission gear 25, a transmission chain 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com