Textile fabric drying box high in drying efficiency

A technology for textiles and drying boxes, applied in drying, dryers, progressive dryers, etc., can solve problems such as inability to dry textiles, prolong drying time, and reduce drying quality, so as to improve drying efficiency. Drying efficiency and quality, the effect of saving drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

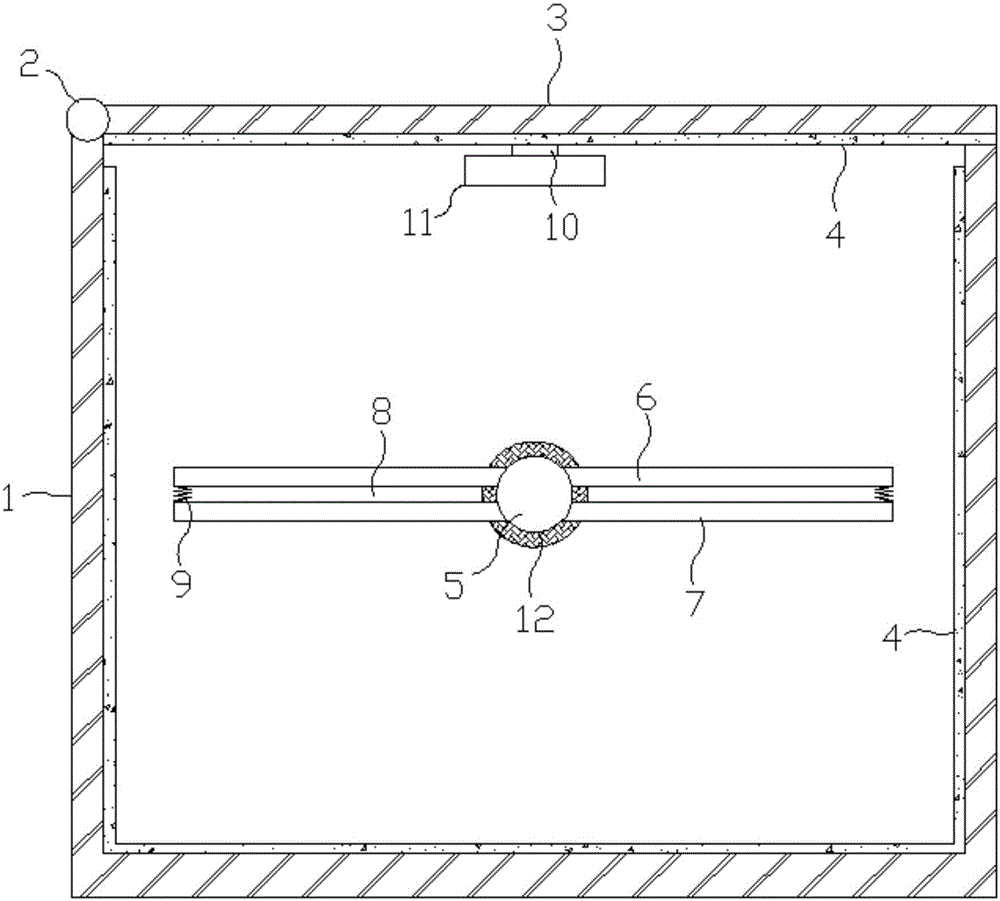

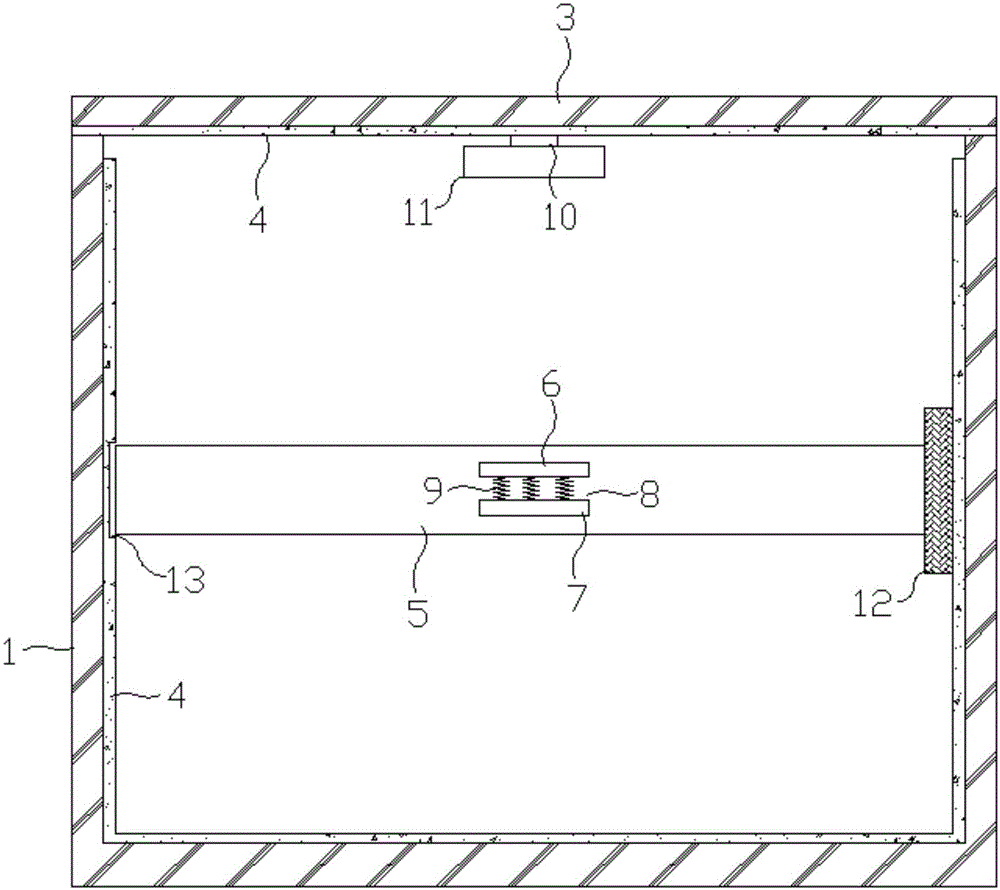

[0016] Example: such as Figure 1-2 As shown, the present invention provides a textile drying box with high drying efficiency, comprising a box body 1 and a motor 12 arranged on one side of the box body 1, and the motor 12 is provided with an electric rotating shaft 5, so A first splint 6 and a second splint 7 are arranged on the electric rotating shaft 5 and a splint gap 8 is set between the first splint 6 and the second splint 7 .

[0017] Further, the box body 1 is hinged with the cover plate 3 through the rotating shaft 2, and a support 10 and a heater 11 fixed on the support 10 are arranged on one side of the cover plate 3, which can continuously provide heat to dry the textiles; the first A number of springs 9 are arranged between the clamping plate 6 and the second clamping plate 7, which can clamp the textile and prevent the textile from falling off during the drying process.

[0018] The inner side of the box body 1 and the cover plate 3 is provided with a heat insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com