Machining process of aero-engine blade

A technology of aero-engine and processing technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low processing efficiency, prone to large deformation, scattered process distribution, etc., to facilitate clamping and positioning , Guarantee the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

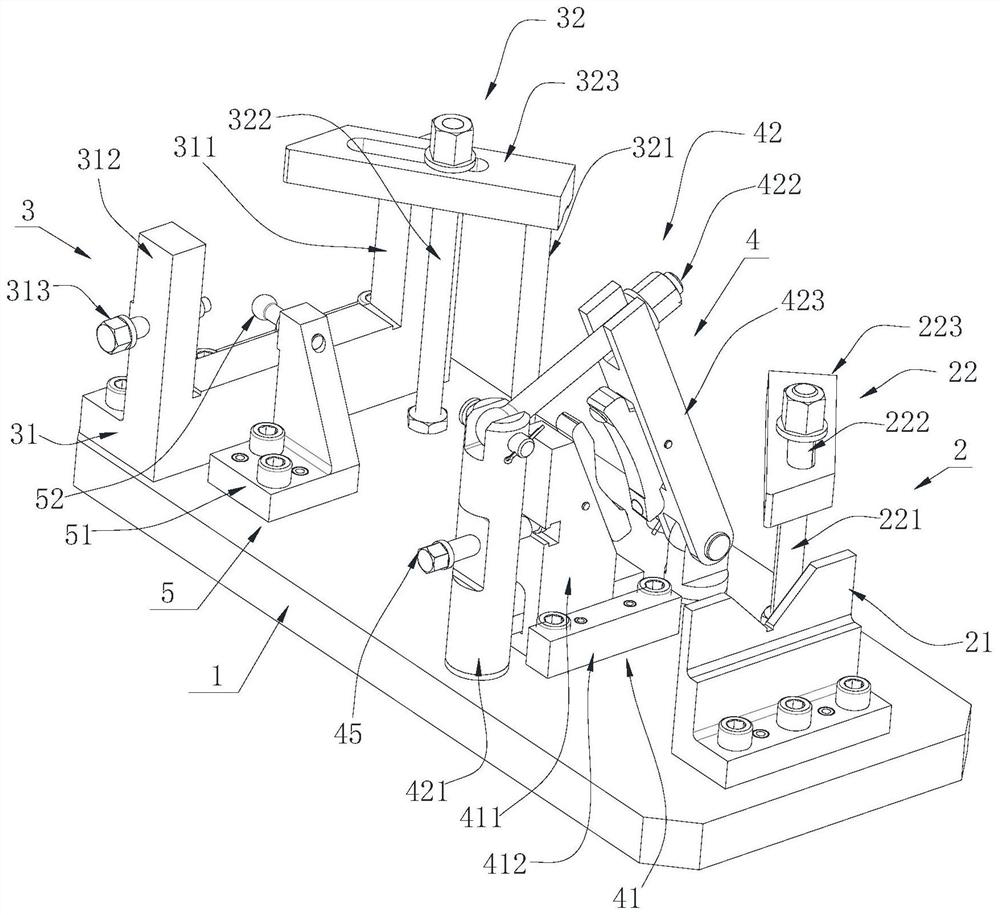

[0057] Please refer to image 3 with Figure 4 , the clamping device includes a base 1, a first pressing mechanism 2, a second pressing mechanism 3 and a supporting fastening mechanism 4, and the first pressing mechanism 2 and the second pressing mechanism 3 are longitudinally arranged at both ends of the base 1 respectively The supporting fastening mechanism 4 is arranged between the first pressing mechanism 2 and the second pressing mechanism 3 , and an axial positioning mechanism 5 is arranged between the first pressing mechanism 2 and the second pressing mechanism 3 . The blank includes a square process table, a mounting plate, a blade, a round table and a circular process table arranged in sequence. The first pressing mechanism 2 is used to clamp the round table or the circular craft table of the blank, the supporting fastening mechanism 4 is used to clamp the blade of the blank, and the second pressing mechanism 3 is used to clamp the mounting plate of the blank As wit...

Embodiment 2

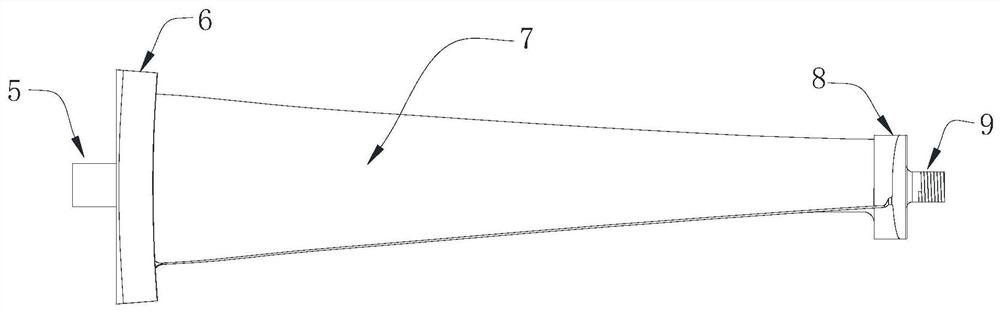

[0074] Please refer to figure 1 and figure 2 , a machining process for an aeroengine blade, comprising a blank, the blank comprising a square process table 53, a mounting plate 6, a blade 7, a round table 8, and an assembly shaft 9 arranged along the axial direction of the round table 8;

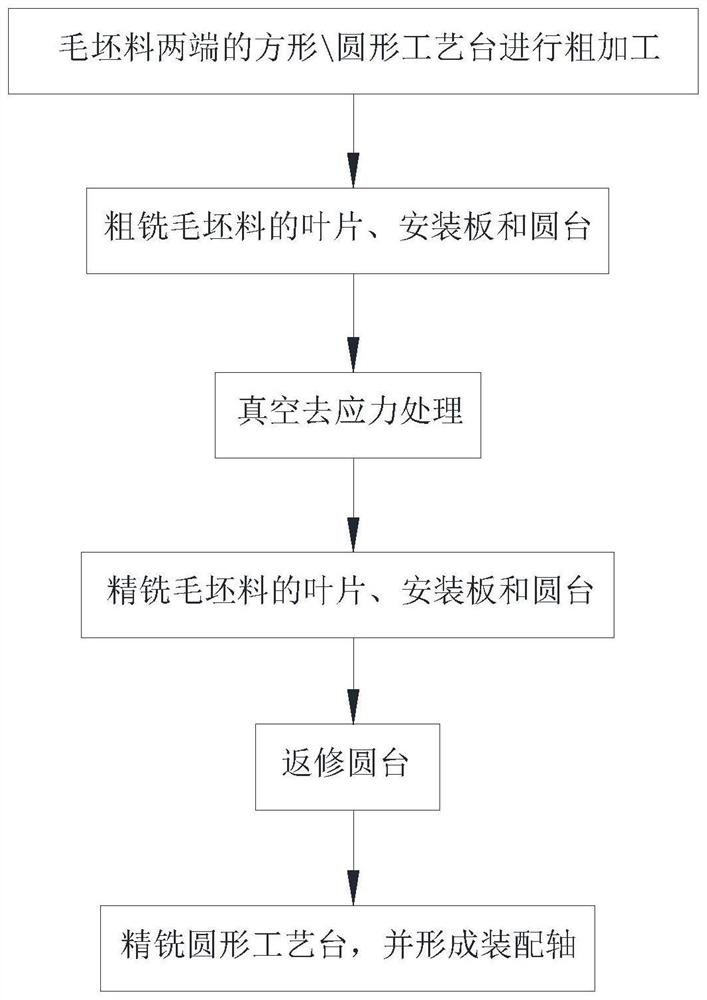

[0075] The processing technology based on above-mentioned raw material comprises the following steps:

[0076] S1: the blade 7 is clamped in the third compression chamber formed by the first floating support block 44 and the second floating support block 46, and the square process table 53 and the circular process table 9 are rough-machined on the machine tool; During the processing of the blank, a relatively accurate benchmark can be established, and at the same time, it is convenient to perform clamping operations on the square craft table 53 and the circular craft table 9;

[0077] S2: Place the square process table 53 in the second compression cavity formed by the U-shaped second comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com