Product separation box and detection and separation method thereof

A separation method and product technology, applied in the field of product distribution box and its detection and separation, can solve the problems of large data storage, increase the production cost of the enterprise, and affect the secondary classification, etc., achieve a high degree of automation, reduce labor costs, The effect of high classification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

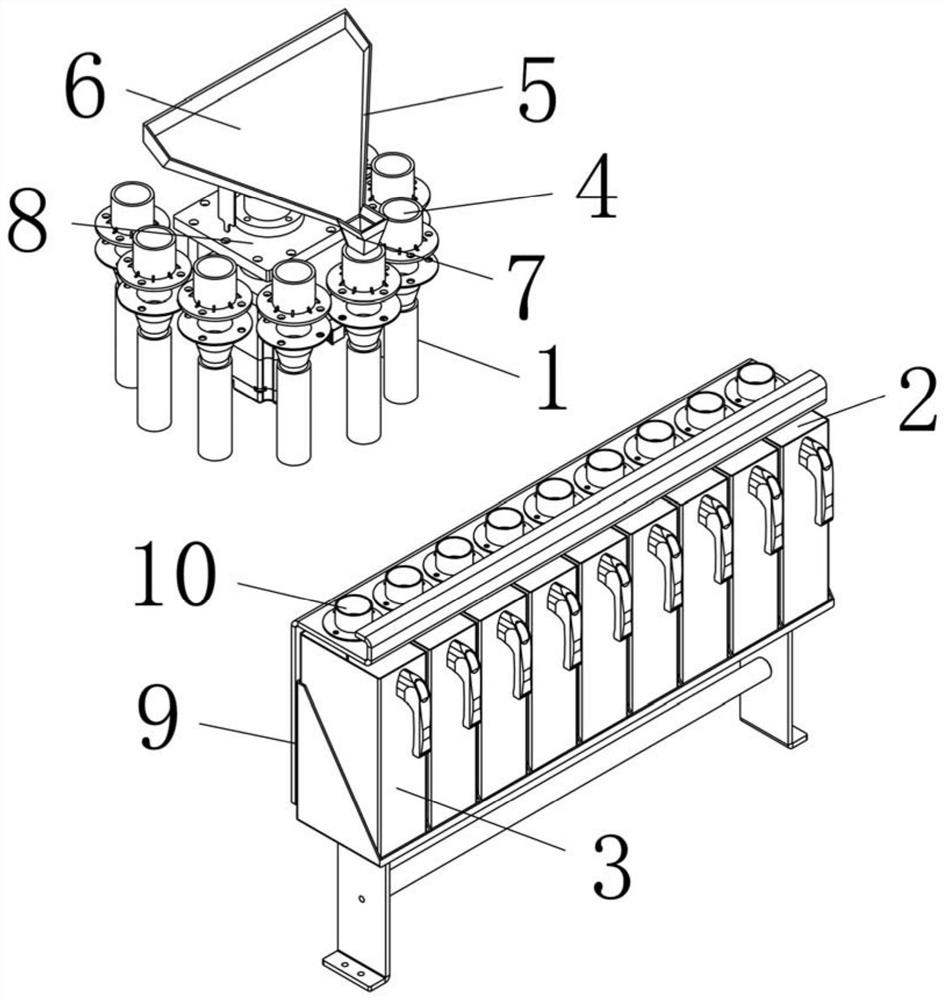

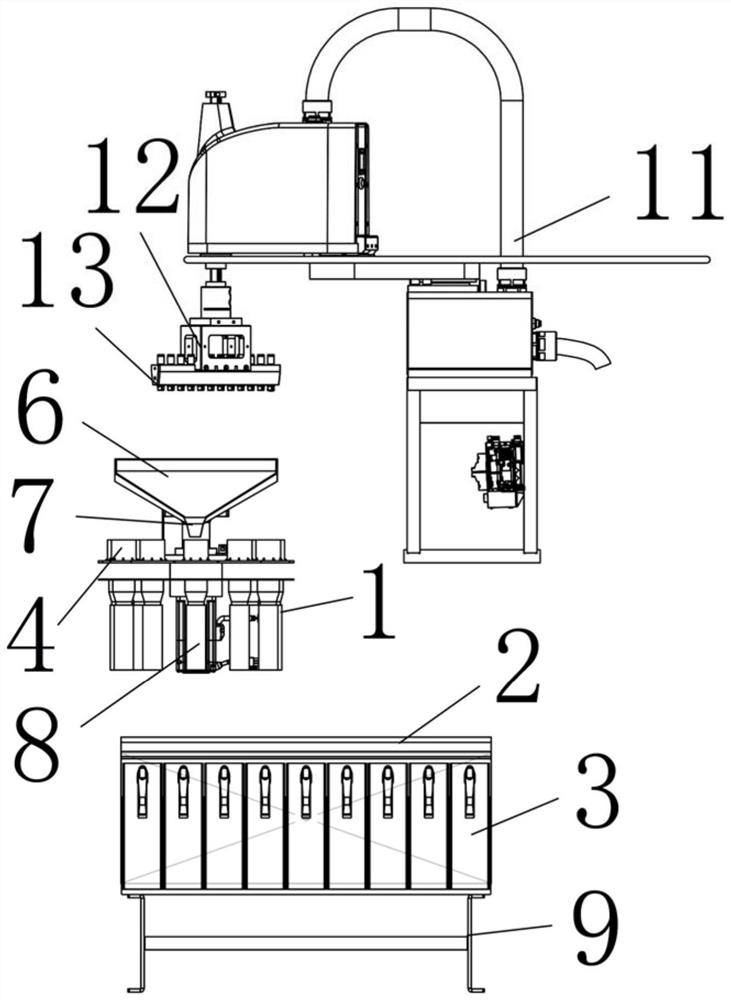

[0050] Example as attached figure 1 As shown, a product distribution material box includes a material distribution device 1, a material receiving device 2 and a control system, and the material receiving device 2 includes several material boxes 3 placed side by side, each of the material boxes 3 has Correspondingly, a first material inlet 4 is provided, and the material distribution device 1 includes a mobile device and a material distributor 5 connected to the mobile device, and the material distributor 5 includes a material storage tray 6 and a material outlet 7, so The moving device drives the discharge port 7 to move to form a moving track, the first material inlet 4 is arranged below the moving track, and the moving device includes a rotating device and / or a lateral moving device;

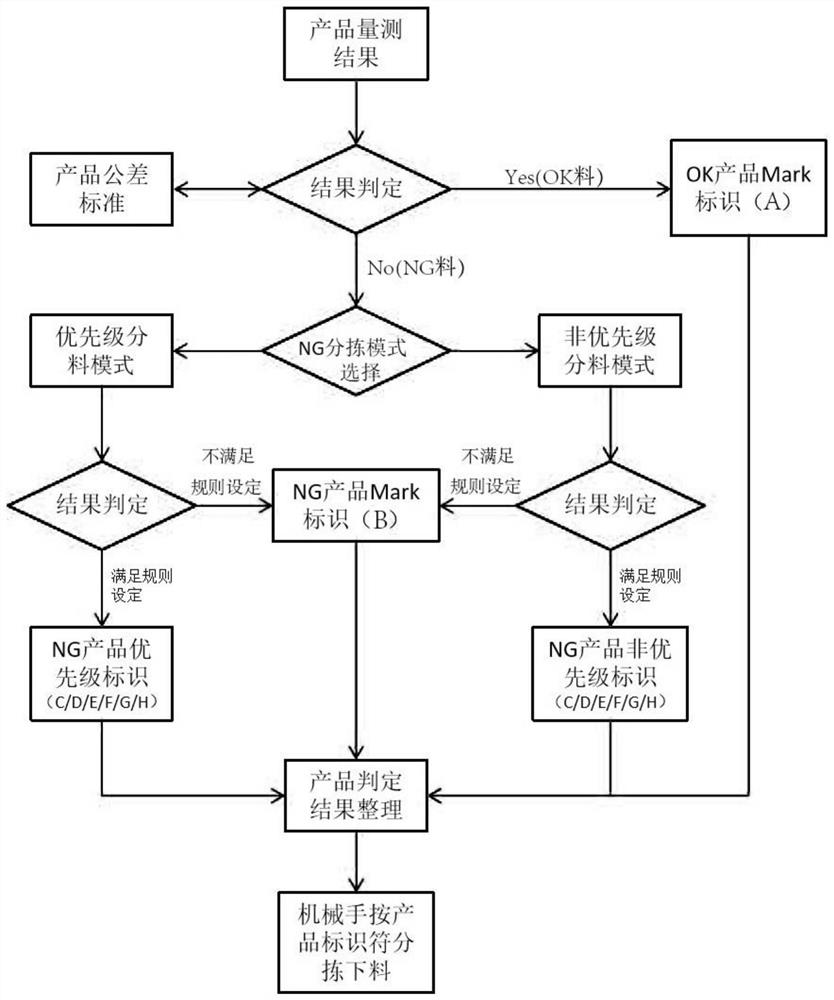

[0051] The control system includes a main control unit, a data storage unit, a data processing unit and a drive unit, and the main control unit is used to transmit signals to other units and r...

Embodiment 2

[0088] This embodiment is carried out on the basis of the above-mentioned embodiment 1, and the similarities with the above-mentioned embodiment will not be repeated.

[0089] In this embodiment, the moving device is a lateral moving device, and the lateral moving device includes a slide rail and a mount connected to the slide rail, the dispenser is mounted on the mount, and the lateral moving device drives out The material port moves laterally to form a moving track, and several first material inlets are distributed below the moving track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com