Full-automatic backwashing self-cleaning filter for filtering lubricating oil and fuel oil

A backwashing and fully automatic technology, which is applied in the direction of fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of frequent replacement of filter elements, achieve good flushing effect, reduce long-term operating costs, and avoid losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

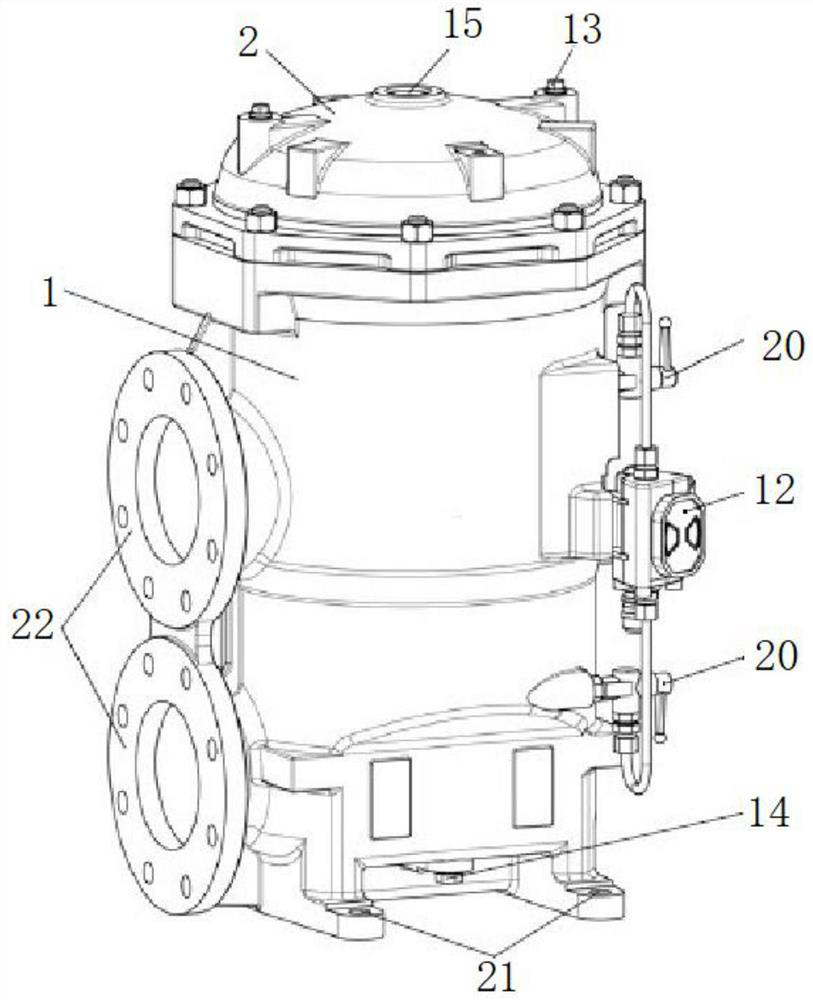

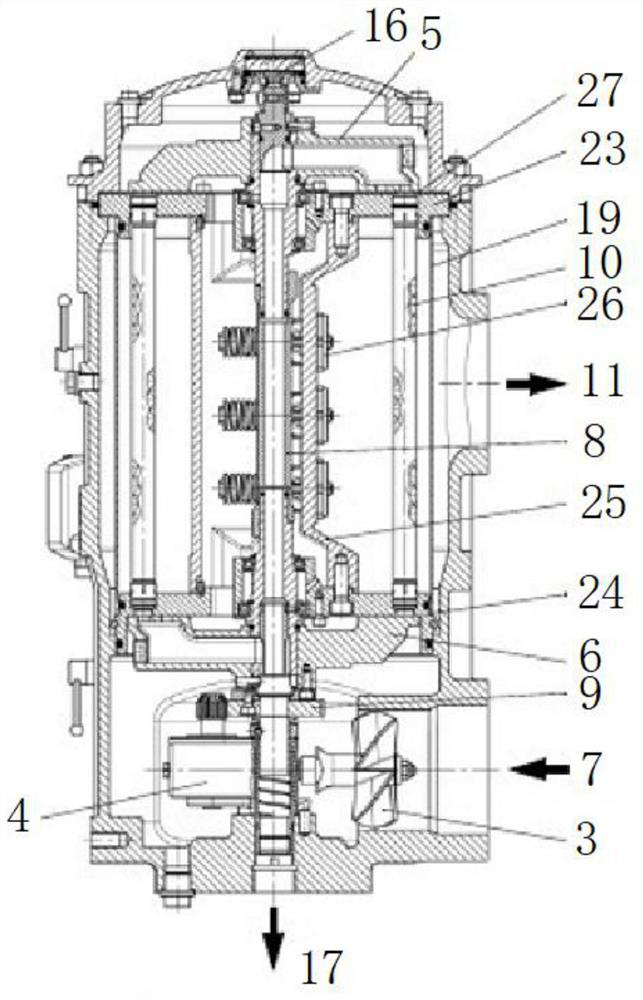

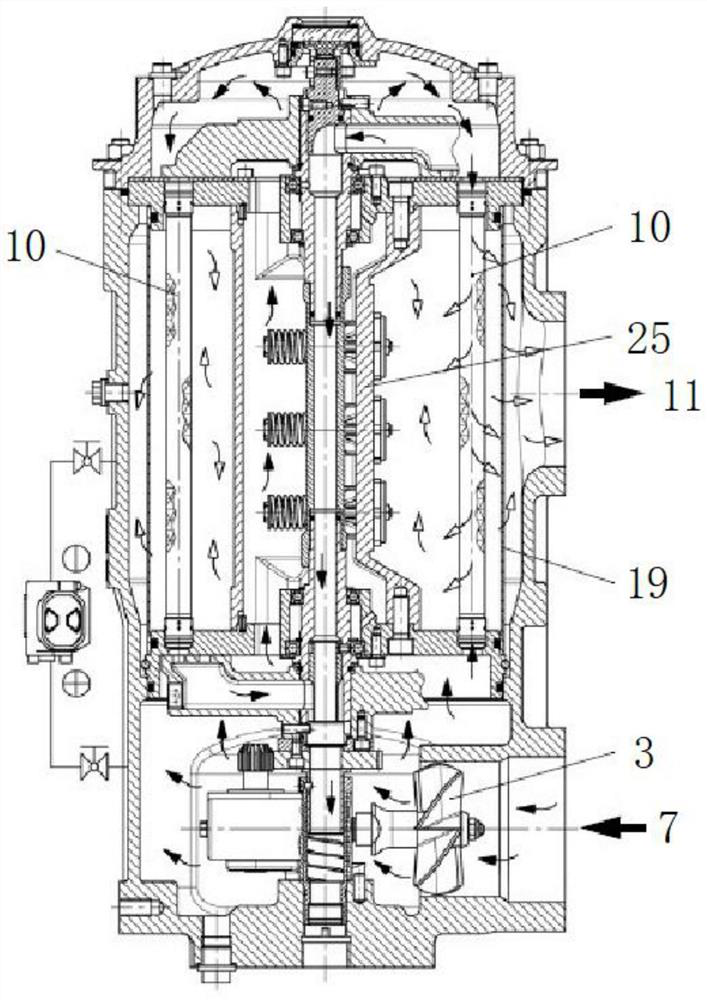

[0027] like figure 1 and 2 As shown, the present invention provides a fully automatic backwashing self-cleaning filter for filtering lubricating oil and fuel oil, including a filter housing 1, an outer cover 2, a backwashing device, a differential pressure indicator 12, and a filter element assembly. The filter housing 1 includes all pipeline connections and the connecting ports of the air-releasing plug 13 , the residual plug 14 and the differential pressure indicator 12 . The outer cover 2 and the shell 1 are tightened by bolts. A backwashing device with double flushing arms (5 and 6) is built into the housing 1. The function of the backwashing device can be checked through a sight glass 15 on the housing 2 . A differential pressure monitor is optional to measure the differential pressure between the filter inlet and outlet. This pressure differential across the filter increases as the filter element becomes increasingly fouled. The differential pressure indicator 12 vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com