Method for recovering and monitoring experimental waste liquid

A waste liquid recovery and waste liquid collection technology, applied in separation methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as monitoring and reminders, and no solutions are mentioned, and achieve improved safety and good ventilation. Function, effect of safe working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The method for recovering and monitoring experimental waste liquid provided by the present invention comprises the following steps:

[0056] S1: Pour the experimental waste liquid into the waste liquid recovery port, filter through the filter screen of the waste liquid recovery port, and then flow to the waste liquid collection barrel along the waste liquid pipeline;

[0057] S2: During the process of collecting waste liquid by the waste liquid collection barrel, the liquid level sensing module monitors the waste liquid level information in the waste liquid collection barrel in real time and transmits it to the central control module, which converts the liquid level information displayed on the display;

[0058] S3: When the waste liquid reaches the preset liquid level, the liquid level sensing module transmits the information to the central control module, and the central control module instructs the alarm module to issue an alarm.

[0059] When the waste liquid reach...

Embodiment 2

[0062] The system that is used for the recovery of experimental waste liquid that cooperates with the method in embodiment 1, its structure is as follows:

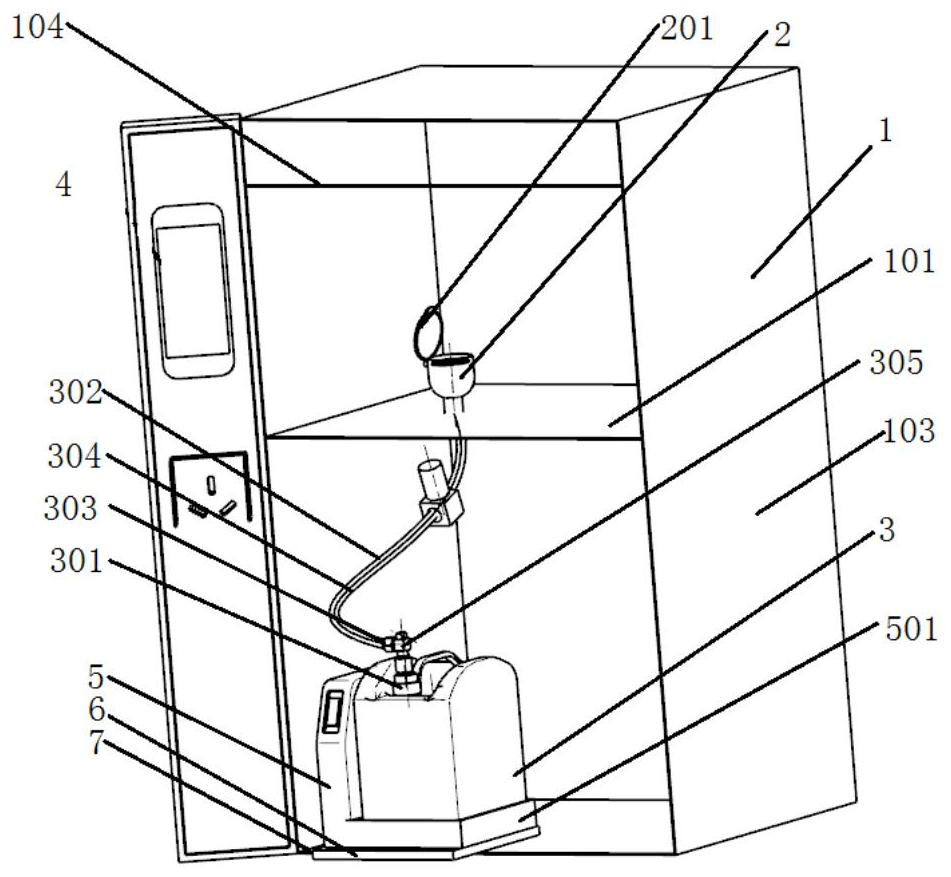

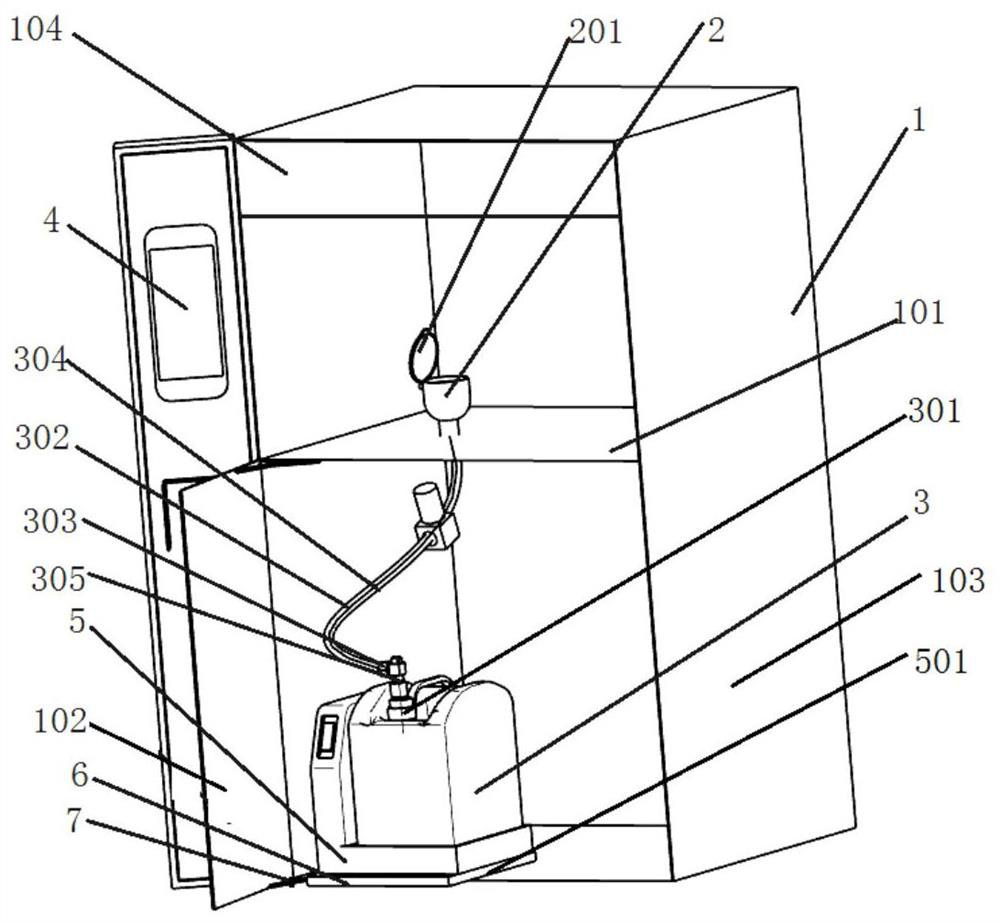

[0063] The system disclosed in the present invention for the recovery of experimental waste liquid is installed in the fume hood 1; there is a table 101 in the fume hood 1, the inside of the table 101 is the rear side wall of the cabinet 103, and the outside is a liftable glass window 104; the lower part of the table top 101 is a cabinet body 103 and a cabinet door 102 matched with the cabinet body 103;

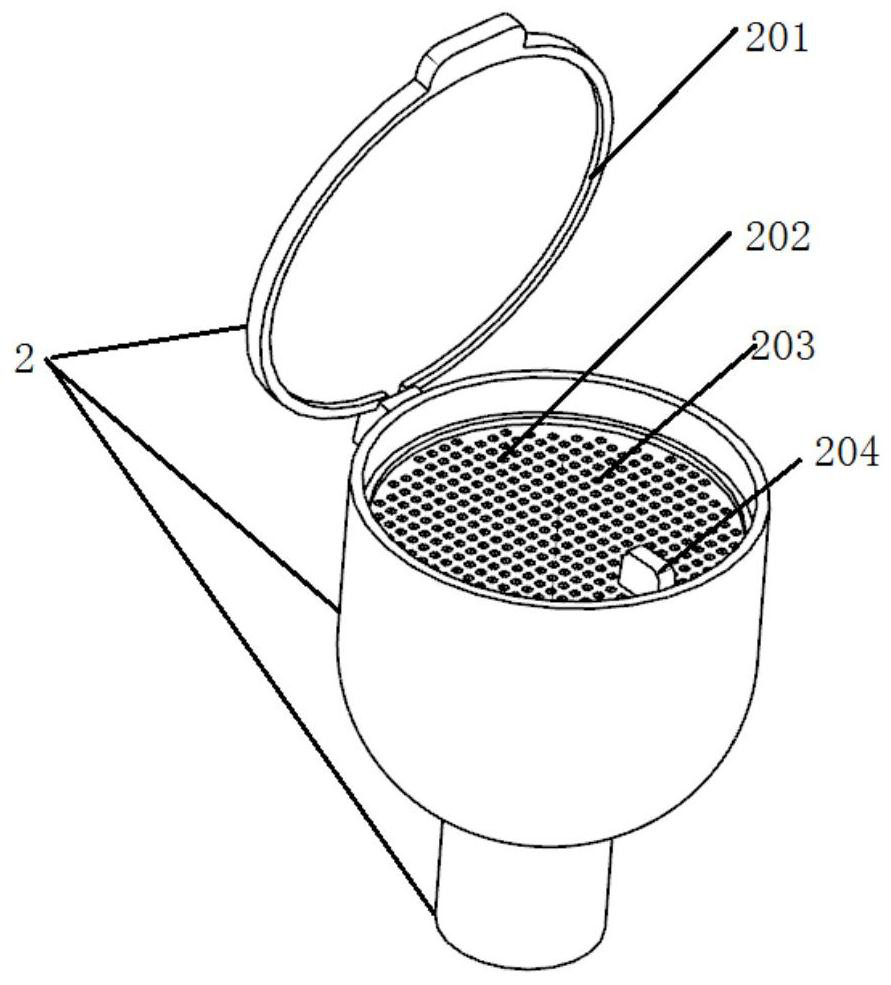

[0064] One to two waste liquid recovery ports 2 are arranged on the table 101 of the fume hood 1, and each waste liquid recovery port 2 has a matching cover 201; the lower part of the waste liquid recovery port 2 passes through the waste liquid pipe 302 A waste liquid collection bucket 3 is connected; the waste liquid collection bucket 3 is located under the table 101 of the fume hood 1;

[0065] The waste liquid collect...

Embodiment 31

[0070] as attached Figure 4 As shown, the electronic control structure of the system used for experimental waste liquid recovery matched with the method in Example 1 is as follows:

[0071] The system includes: a central control module, a liquid level sensing module, an alarm module, and a display module; the central control module is respectively connected with the liquid level sensing module, the alarm module, and the display module;

[0072] The liquid level sensing module transmits the collected liquid level information in the waste liquid collection bucket to the central control module;

[0073] The central control module, according to the liquid level information transmitted by the liquid level sensing module, instructs the alarm module to issue an alarm; and instructs the display module to display the liquid level information monitored by the liquid level sensing module;

[0074] An alarm module, which alarms according to the instructions of the central control module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com