Down filling machine down filling pipe mechanism with down filling depth adjusting function

A down filling machine, deep technology, applied in sewing tools, toys, entertainment, etc., can solve the problems of bending or deformation of the sealing ring, easy wear of the sealing ring, weakening of the air pressure of the down filling tube, etc., to reduce wear and tear Chance, the effect of increasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

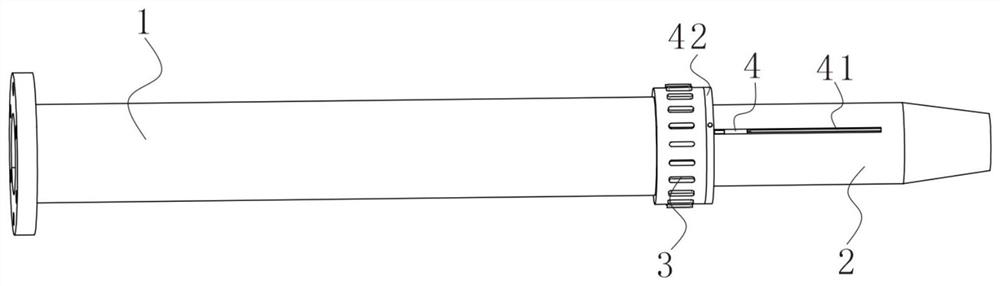

[0023] The present invention provides a technical solution: it is used for the filling tube mechanism of the down filling machine with the function of adjusting the down filling depth, please refer to figure 1 , including a down-filled outer tube 1 and a down-filled inner tube 2;

[0024] see figure 1 , figure 2 and Figure 5 , the velvet-filled inner tube 2 is slidably inserted into the inner cavity of the velvet-filled outer tube 1, and the outer wall on the right side of the velvet-filled outer tube 1 is rotated to install a threaded sleeve 3, and the threaded sleeve 3 is set on the outer wall of the velvet-filled inner tube 2, The outer wall of the velvet-filled inner tube 2 is provided with an external thread that matches the threaded sleeve 3, and the threaded sleeve 3 is fixed on the outer wall of the velvet-filled inner tube 2 by cooperating with the threaded sleeve 3 through the external thread. 3. Change the position of the threaded casing 3 on the outer wall of ...

Embodiment 2

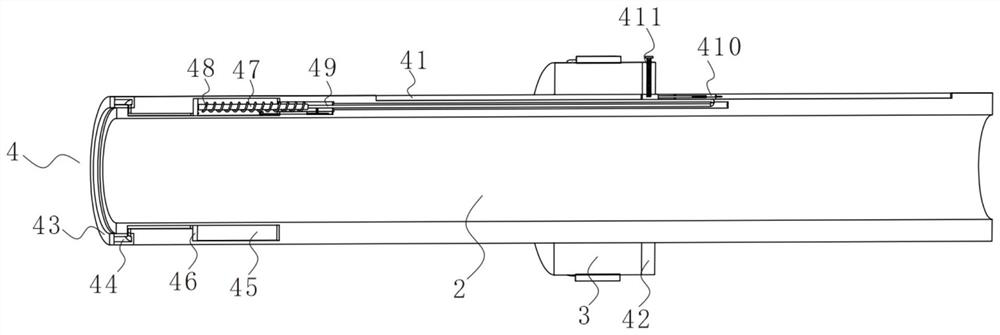

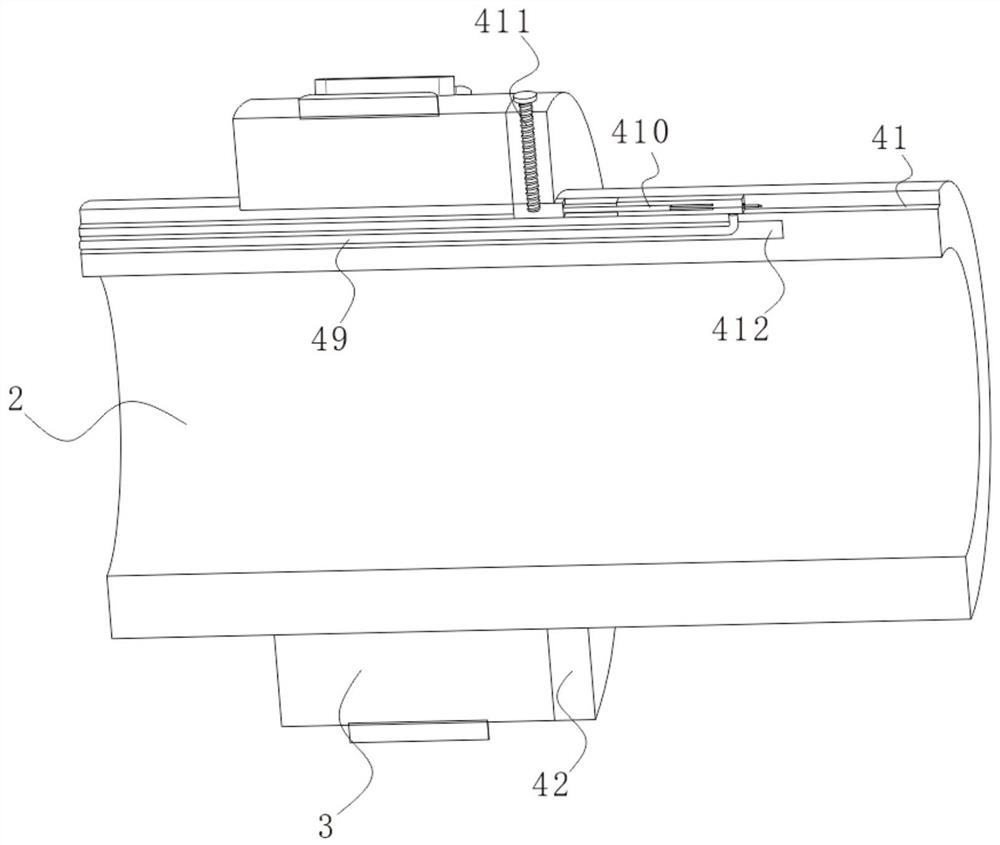

[0027] see figure 2 , image 3 and Figure 4 , on the basis of Embodiment 1, the threaded sleeve 3 right side outer wall is rotated and installed with a connecting plate 42, the connecting plate 42 is sleeved on the outer wall of the down-filled inner tube 2, and the outer wall of the top of the connecting plate 42 is screwed with a threaded rod 411, guiding Block 410 top left outer wall is provided with fixing groove 4101, and the bottom end of threaded rod 411 extends in the inner chamber of fixing groove 4101, turns threaded rod 411, and makes the bottom end of threaded rod 411 be inserted in the inner cavity of fixing groove 4101, makes connection The plate 42 is connected with the guide block 410, so that when the threaded sleeve 3 moves with the down-filled outer tube 1 to change the overall length of the down-filled tube, it will move together with the guide block 410 to trigger the adjustment device 4 and make the sealing The ring 43 is not in contact with the inside ...

Embodiment 3

[0030] see image 3 with Figure 4 , on the basis of Embodiment 2, the guide block 410 includes a connecting block 4102 that is slidably installed in the inner cavity of the guide groove 41, the fixed groove 4101 is located on the connecting block 4102, and a movable block 4103 is fixedly installed on the outer wall of the right side of the connecting block 4102. The movable block The right end of the outer wall of 4103 is slidingly sleeved with an installation sleeve 4104, and the installation sleeve 4104 is slidably installed in the inner cavity of the guide groove 41. The outer wall at the bottom of the installation sleeve 4104 is fixedly connected with the end of the stay rope 49 away from the pull rod 47, and the right side of the inner cavity of the installation sleeve 4104 runs through Plug the limiting rod 4105, the left end of the limiting rod 4105 is fixedly connected with the outer wall on the right side of the movable block 4103, the outer wall on the right side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com