Wall bushing and tubular bus connecting and supporting fitting

A technology for wall-piercing bushings and pipe busbars, which is applied in the installation of busbars, fully enclosed busbar devices, and cables. It can solve the problems of high requirements for connecting fittings, and achieve the effect of avoiding damage and avoiding excessive stress damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

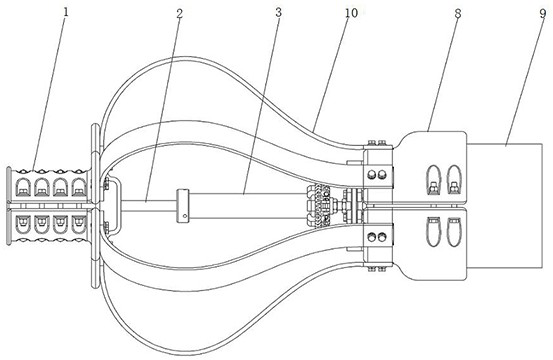

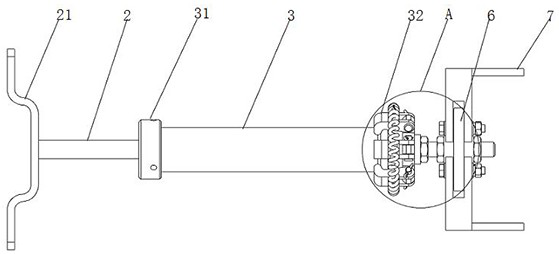

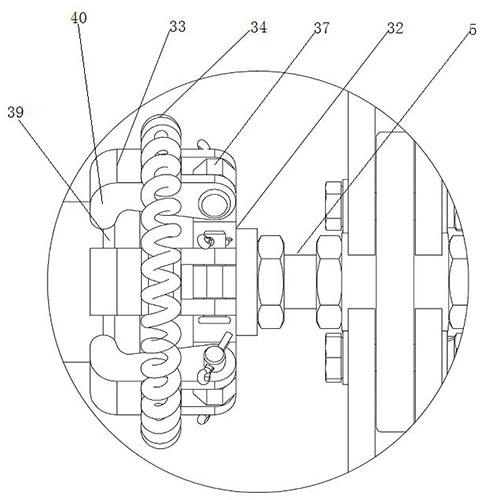

[0054] like figure 1 As shown, the supporting fittings for the connection between the wall bushing and the pipe busbar provided in this embodiment include a connecting supporting device, and the connecting supporting device is provided with a first connecting piece and a second connecting piece that are slidably assembled, through the first connecting piece and the second connecting piece The relative sliding between the second connecting parts can realize the relative movement between the wall bushing and the tube nut. In this embodiment, by adopting the sliding fit between the first connecting piece and the second connecting piece, it is avoided to design corresponding sliding turntables according to different pipe busbars, and the technical problem of high requirements for connecting fittings in the installation process is solved.

[0055] Specifically, if figure 1 As shown, the connection support fittings include a bushing terminal holding clip 1 and a pipe mother holding...

specific Embodiment 2

[0067] It differs from Embodiment 1 mainly in that: in Embodiment 1, the second connecting piece is a guide cylinder, and the universal connection structure is arranged between the second connecting piece and the pipe nut holding clip. In this embodiment, the universal connection structure is arranged between the first connecting piece and the clamp of the bushing terminal, which also enables relative swing between the pipe busbar and the wall-penetrating bushing.

[0068] Of course, in other embodiments, universal connection structures can also be provided between the first connecting piece and the bushing terminal holding clip, and between the second connecting piece and the pipe mother holding clip, so as to realize the connection between the pipe busbar and the through-wall The relative swing of the casing.

specific Embodiment 3

[0070] The main difference between it and Embodiment 1 is: in Embodiment 1, the first connecting part is a guide rod, the second connecting part is a guiding cylinder, and the guiding rod and the guiding cylinder are slidably supported and assembled. In this embodiment, both the first connecting piece and the second connecting piece are supporting plates, and the supporting plates are rigid parts, and one of the supporting plates is provided with a long slot hole, and the other supporting plate is provided with a round hole. When the two supporting plates When the guide is fitted, the long slot hole and the round hole are connected correspondingly, and the pin shaft is installed so that the long slot hole and the round hole are connected by the pin shaft, and the pin shaft can slide along the long slot hole. At this time, the two connecting parts can be realized The relative sliding assembly in the left and right directions, of course, in order to achieve effective support, two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com