High-cohesiveness ceramic coating slurry and preparation method thereof

A high-adhesion, ceramic coating technology, used in polymer adhesive additives, adhesives, structural parts, etc., can solve problems such as large thermal shrinkage, weak pole piece adhesion, and weakened ceramic thermal shrinkage support capabilities. , to achieve good thermal support, improve thermal shrinkage resistance, and reduce PVDF content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention discloses a preparation method of a highly cohesive ceramic coating slurry, which comprises the following steps:

[0023] Step 1, adding PVDF glue and kneading agent into deionized water and stirring, so that PVDF glue and kneading agent are combined to form large-grained PVDF micelles, and a primary slurry of large-grained PVDF micelles is obtained;

[0024] Step 2, adding ceramic powder, glue, dispersant and wetting agent into the primary slurry of large-particle PVDF micelles and stirring to obtain large-particle PVDF micellar slurry.

[0025] The large-particle PVDF micellar slurry includes the following raw materials in parts by weight: 20-40 parts of large-particle PVDF primary slurry, 50-70 parts of ceramic powder, and 5-15 parts of glue. The materials include the following raw materials in parts by weight: 5-7 parts of PVDF glue, 1-3 parts of kneading agent, and 1-3 parts of deionized water.

[0026] In step 1, the stirring speed is 1000-2000 rpm,...

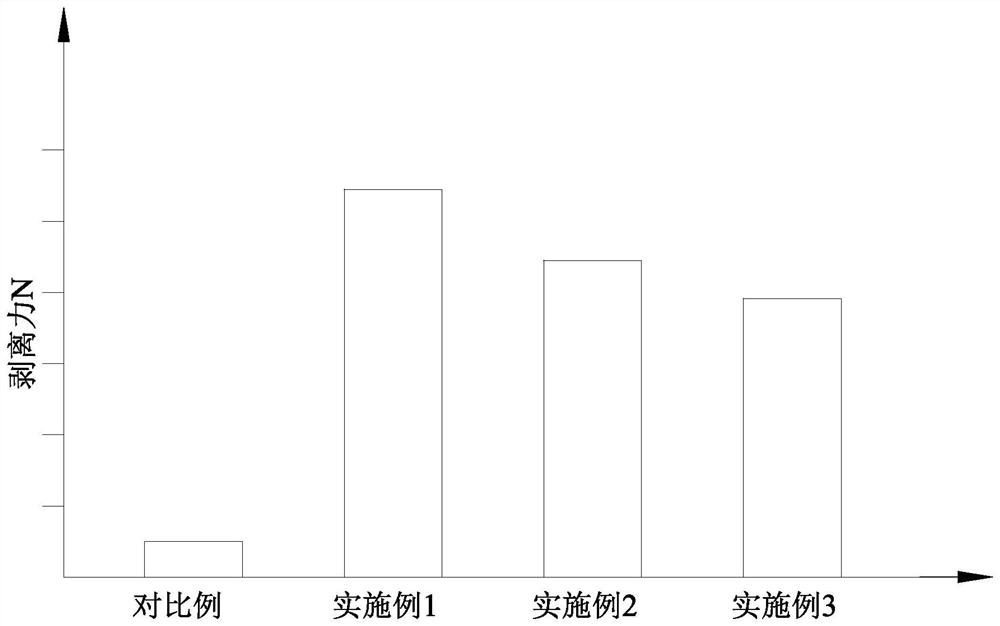

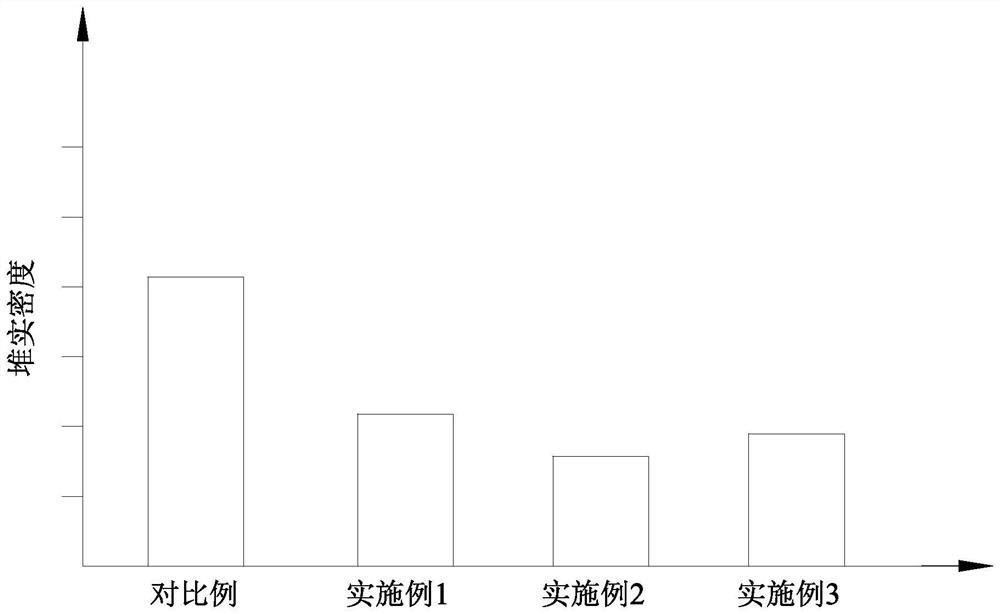

Embodiment 1

[0030] Select 5 parts of polyvinylidene fluoride, 1 part of polyallyl nitrile and 1.5 parts of deionized water to mix, stir at 30°C and a stirring speed of 1200 rpm for 100 min, then add 55 parts of alumina, 6 parts of styrene-butadiene rubber After mixing 2 parts of maleic anhydride-vinyl acetate and 3 parts of fluoroalkyl methoxy ether alcohol, stir at 30°C and a stirring speed of 1200 rpm for 60 minutes to prepare a large-particle PVDF micellar slurry. The large-particle PVDF micellar slurry is coated on the diaphragm to obtain a high-bond ceramic coating diaphragm.

Embodiment 2

[0032] Select 6 parts of polyvinyl alcohol resin, 1.5 parts of polyvinyl sulfone and 2 parts of deionized water to mix, stir for 100 min at 30 ° C and a stirring speed of 1500 rpm, and then add 60 parts of silica, 10 parts of epoxy resin, After mixing 3 parts of polyethylene glycol and 5 parts of fluoroalkyl ethoxy ether alcohol, stir at 30°C and a stirring speed of 1500 rpm for 50 minutes to prepare a large-particle PVDF micellar slurry. The slurry is coated on the diaphragm to obtain a high-adhesion ceramic coating diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com