Contact type measuring head, three-coordinate measuring machine and tool setting gauge

A contact type and measuring head technology, applied in the direction of measuring devices, instruments, etc., can solve the problems affecting the normal operation of the electrical components in the casing, affecting the sealing of the casing, etc., achieving high repeatability, improving measurement accuracy, improving accuracy and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

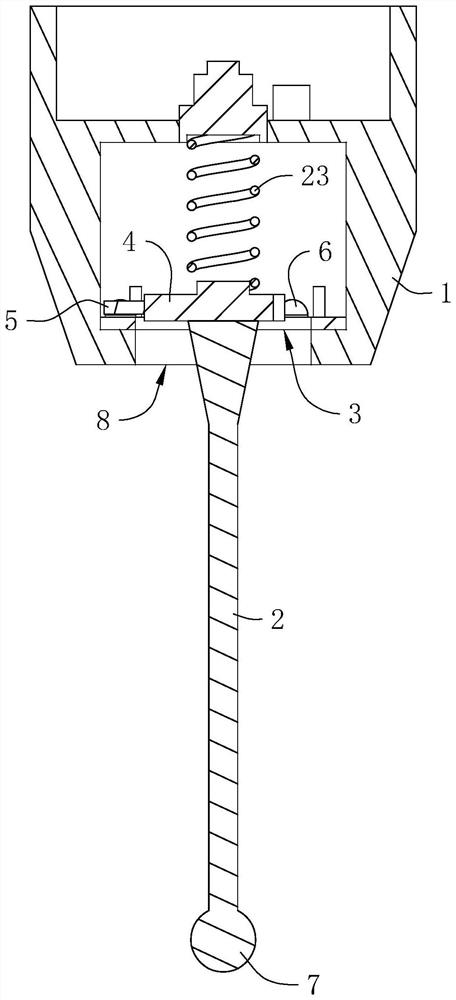

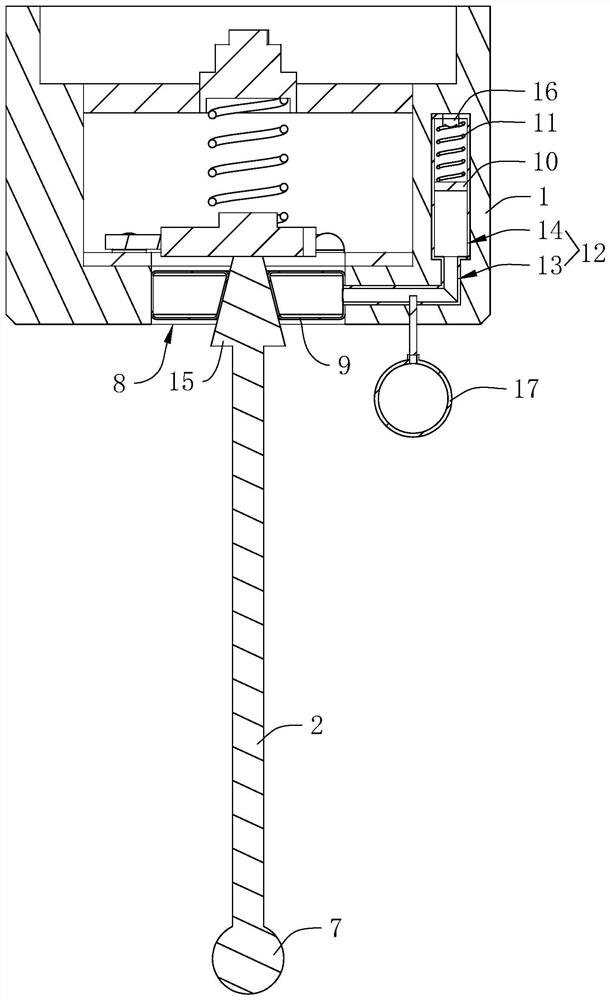

[0043] The embodiment of the present application discloses a touch probe. refer to figure 1 with figure 2 , the contact probe includes a casing 1 and a measuring rod 2, the inner bottom surface of the casing 1 is provided with a placement groove 3, and a mounting plate 4 is placed in the placement groove 3, and a spring 2 23 is fixedly connected to the mounting plate 4, and a spring 2 23 It is vertically arranged, the other end of the spring 23 is fixed in the casing 1, three round rods 5 are fixedly connected equidistantly on the outer wall of the mounting plate 4, and the inner bottom surface of the casing 1 is provided with three groups of switches, three groups of switches and three round rods. The rods 5 are in one-to-one correspondence. The switch includes two balls 6 that are close to each other and are fixedly connected to the inner bottom surface of the casing 1. There is a gap between the two balls 6 for the round rod 5 to snap in, and the round rod 5 snaps in. Wh...

Embodiment 2

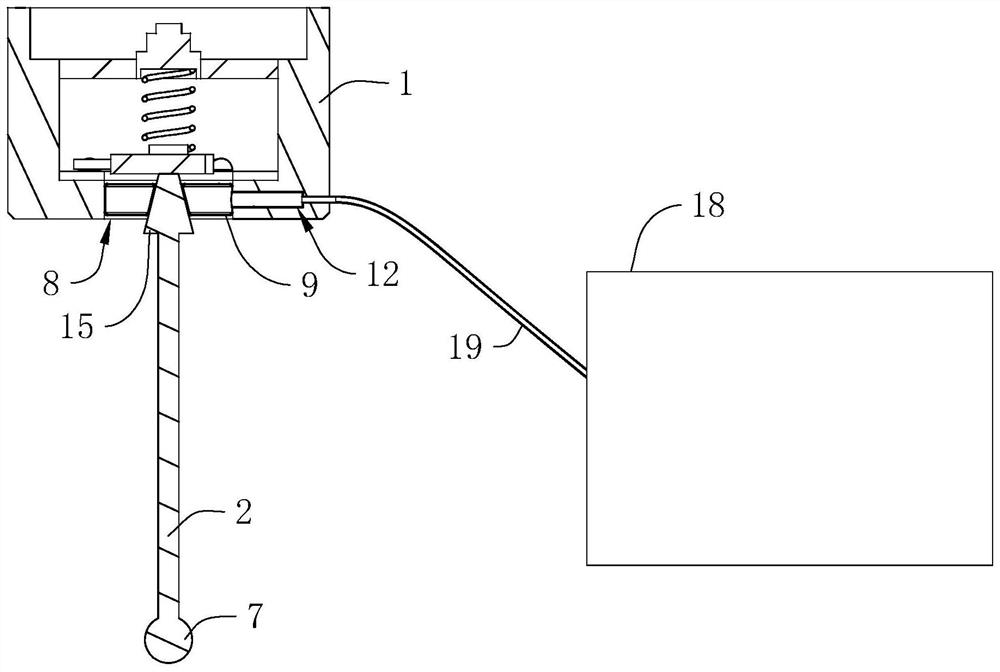

[0052] The difference between this embodiment and embodiment 1 is that, referring to image 3 , the inflation mechanism includes an air pump 18, the air pump 18 is used to be fixed on the installation surface, the installation surface can be the body of a three-dimensional coordinate measuring instrument, or the body of a knife setting instrument, the air outlet of the air pump 18 is connected with a gas pipe 19, and the other end of the gas pipe 19 Connected to the buffer tank 12.

[0053] In addition, a touch switch can be provided on the probe, and the touch switch is used to turn on and off the air pump 18, that is, when the probe touches the workpiece, the air pump 18 no longer inflates the air bag 9, and when the probe is separated from the workpiece, the air pump 18 continues to inflate the air bag 9.

[0054] The implementation principle of a contact measuring head in the embodiment of the present application is: when detecting, the measuring rod 2 touches the workpiec...

Embodiment 3

[0056] The difference between this embodiment and embodiment 1 is that, referring to Figure 4 , the driver includes a cylinder 20, the cylinder 20 is fixedly connected on the outer wall of the casing 1 by screws, and the piston 10 rod of the cylinder 20 is inserted into the buffer groove 12 and fixedly connected to the side of the piston 10 away from the airbag 9.

[0057] In addition, a touch switch can be arranged on the probe, and the touch switch is used to open and close the cylinder 20, that is, when the probe touches the workpiece, the cylinder 20 returns to its position.

[0058] In another embodiment, the driving member includes a screw and a motor. The rotation of the screw drives the piston 10 to move, so as to inflate or deflate the airbag 9 . The motor is used to drive the screw to rotate, and the touch switch is used to turn on and off the motor.

[0059] The implementation principle of a contact probe in the embodiment of the present application is: during dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com