Circumferential array spiral groove piston anti-settling magnetorheological damper

A magnetorheological damper, circular array technology, applied in shock absorbers, shock absorbers, gas-liquid shock absorbers, etc., can solve the problem of affecting the damping performance and damping effect of shock absorbers. and application limitations, can not solve the problem of magnetorheological fluid settlement, etc., to avoid the decline of damping performance and vibration reduction effect, increase the adjustable range, and improve the settlement phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

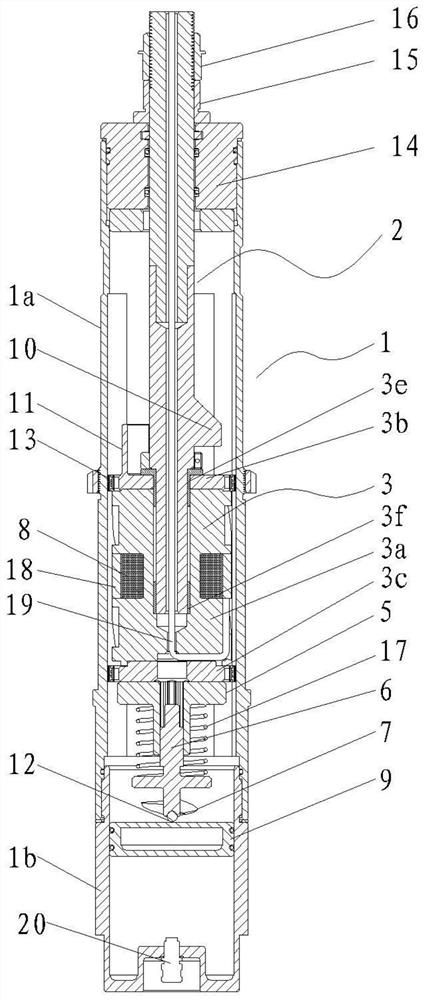

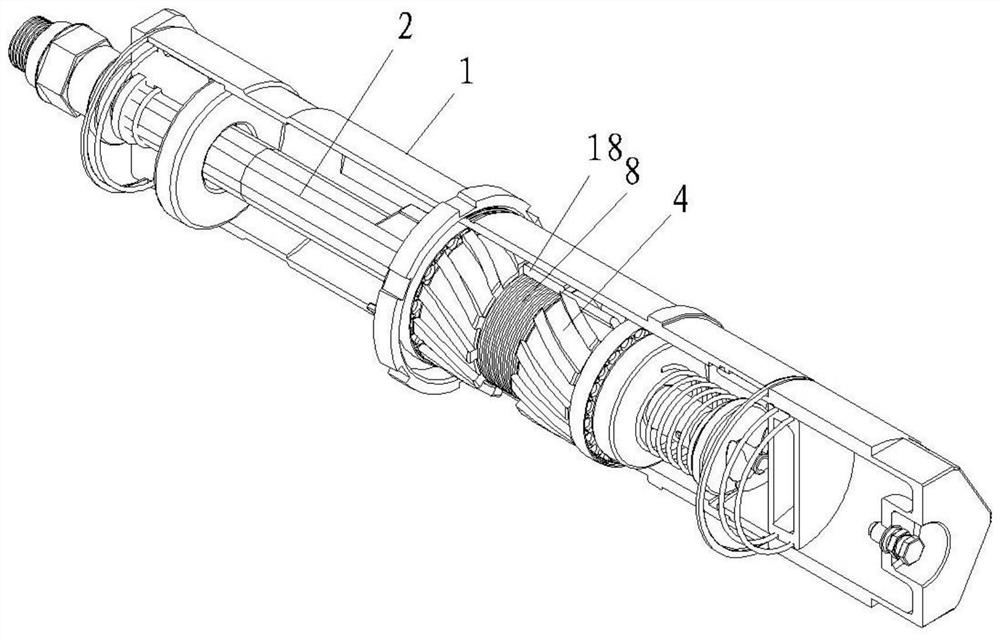

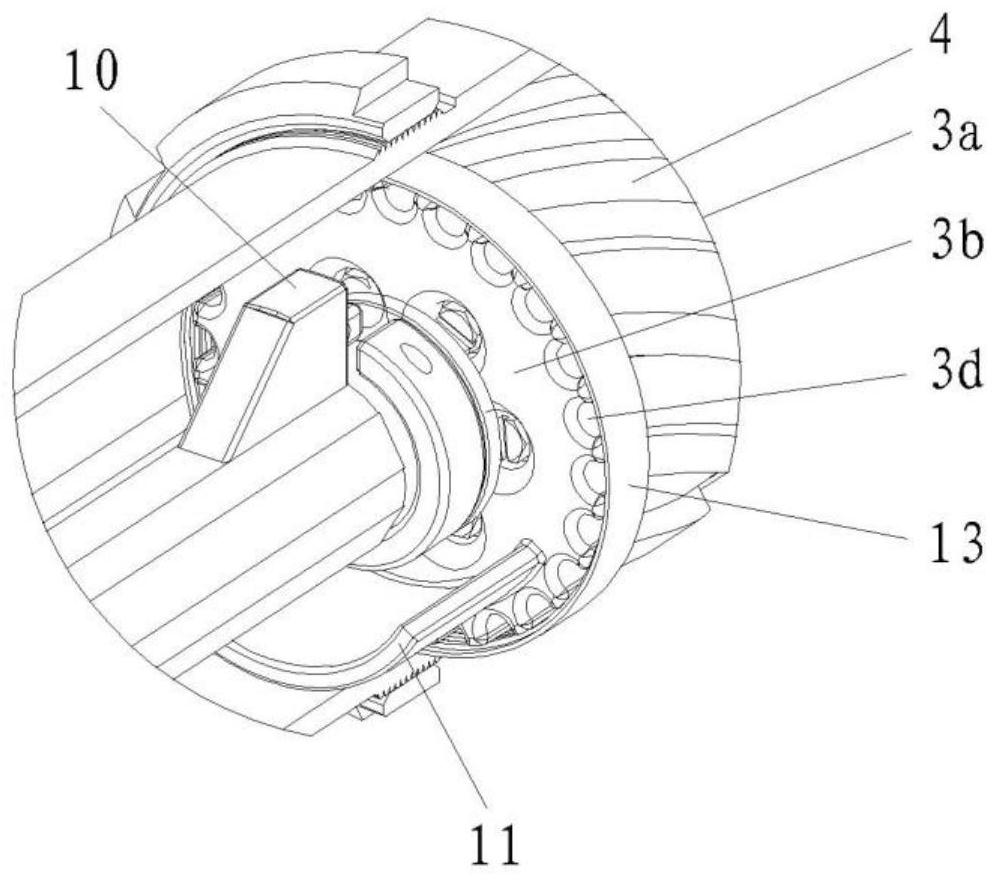

[0021] As shown in the figure: the circular array spiral groove piston anti-settling magnetorheological damper of this embodiment includes a piston cylinder 1, a piston rod 2 that is axially slidably fitted with the piston cylinder, and a piston assembly 3 connected to the piston rod. The piston assembly and the piston rod are rotatably matched with a single degree of freedom, the piston assembly and the inner circular surface of the piston cylinder are axially sealed, slidable and rotatably matched, the stirring assembly is in driving cooperation with the piston assembly, and the outer circular surface of the piston assembly is provided with a spiral Slot 4, the helical groove is connected to the axial end faces of the piston assembly, and when the piston rod drives the piston assembly to slide axially in the piston cylinder, the magnetorheological flow in the space located on both sides of the axial direction of the piston assembly in the piston cylinder The liquid flows thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com