Sleeve valve pipe grouting device and method based on elastic films

A sleeve valve pipe grouting and elastic membrane technology, which is applied in soil protection, infrastructure engineering, roads, etc., can solve the problems of complicated and cumbersome processes, sleeve valve pipes are easily blocked by slurry, and there are residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

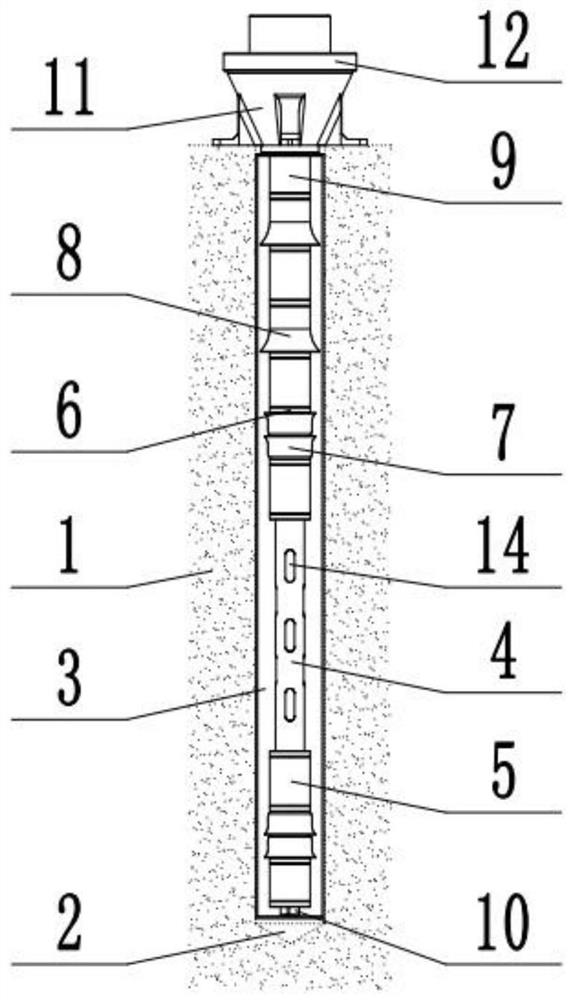

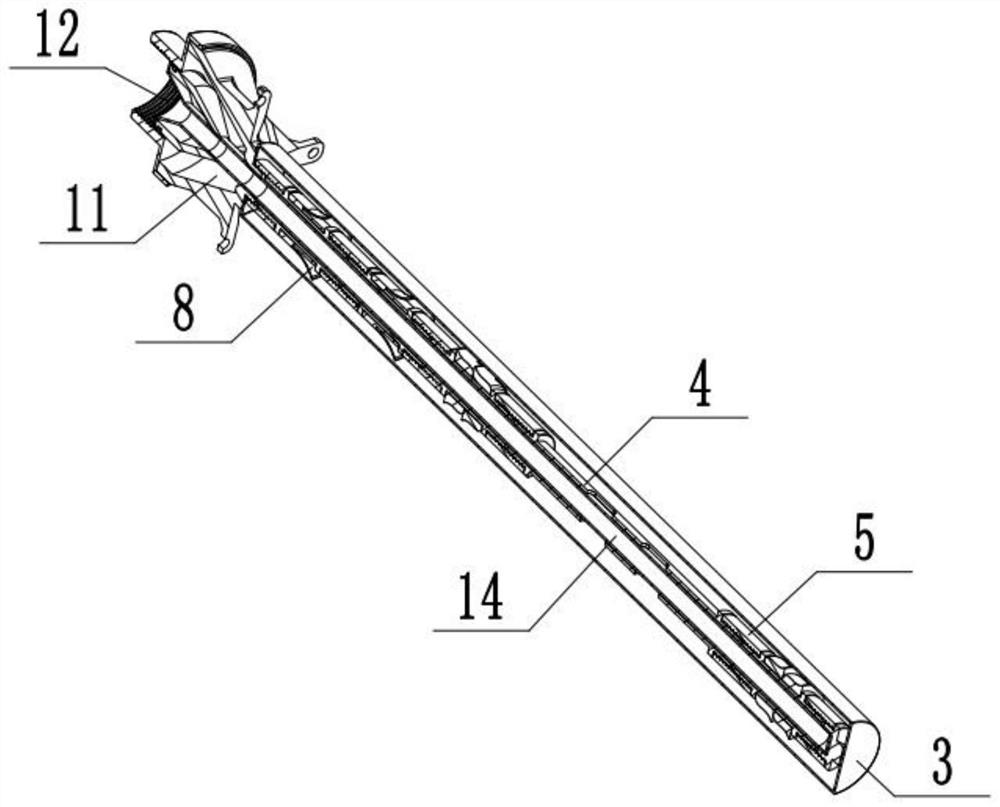

[0034] Combine below Figure 1-10Description of this embodiment, a sleeve valve pipe grouting device based on elastic film, including foundation soil 1, borehole 2, outer elastic film 3, sleeve valve pipe 4, connecting pipe 5, threaded connector 6, and annular sealing ring 7. Bowl-shaped grout stopper 8, connecting pipe 2 9, square plug 10, inner and outer membrane grouting connector 11, grouting sealing cover 12, tight hoop 13, inner elastic membrane 14, foundation soil 1 and inner and outer membrane grouting The grout connector 11 is connected, the bore 2 is connected with the outer elastic membrane 3, the outer elastic membrane 3 is connected with the connecting pipe two 9, and the inner and outer membrane grouting connector 11, the sleeve valve pipe 4 is connected with the connecting pipe one 5, Connecting pipe 1 5 is connected with threaded connector 6, threaded connector 6 is connected with annular sealing ring 7, bowl-shaped grout stopper 8, connecting pipe 2 9, connect...

specific Embodiment approach 2

[0035] Combine below Figure 1-10 This embodiment will be described. This embodiment will further describe the first embodiment. The outer elastic membrane 3 is made of high elastic shrinkage material, and its shape is adapted to the outer wall of the cuff tube.

specific Embodiment approach 3

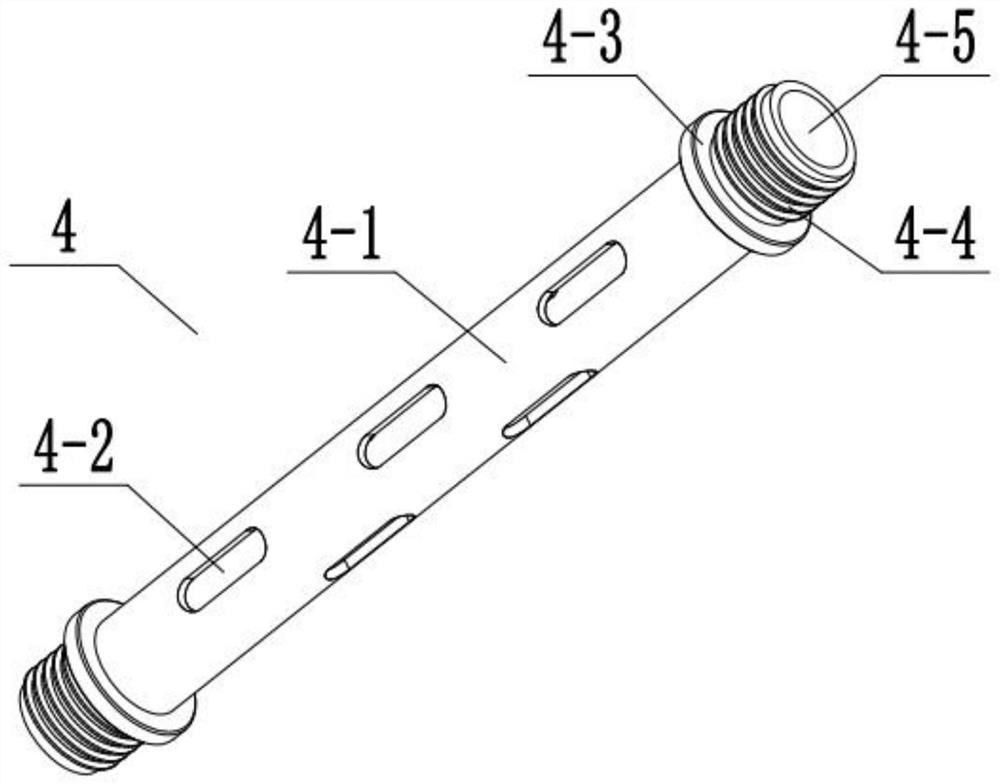

[0036] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the first embodiment, the sleeve valve pipe 4 includes a grouting pipe 4-1, a grouting hole 4-2, a limiting end surface 4-3, an external thread 4- 4. Hole one 4-5, grouting pipe 4-1 is provided with grouting hole 4-2, external thread one 4-4, hole one 4-5, grouting pipe 4-1 and limit end face one 4- 3 fixed connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com