Preparation method of electrocatalytic material B-VS2 for ENRR

A B-VS2, electrocatalysis technology, applied in chemical instruments and methods, electrodes, vanadium compounds, etc., can solve problems such as poor stability, and achieve stable catalytic performance and concentrated size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will be further described in detail through specific embodiments, but the present invention is not limited to the following examples.

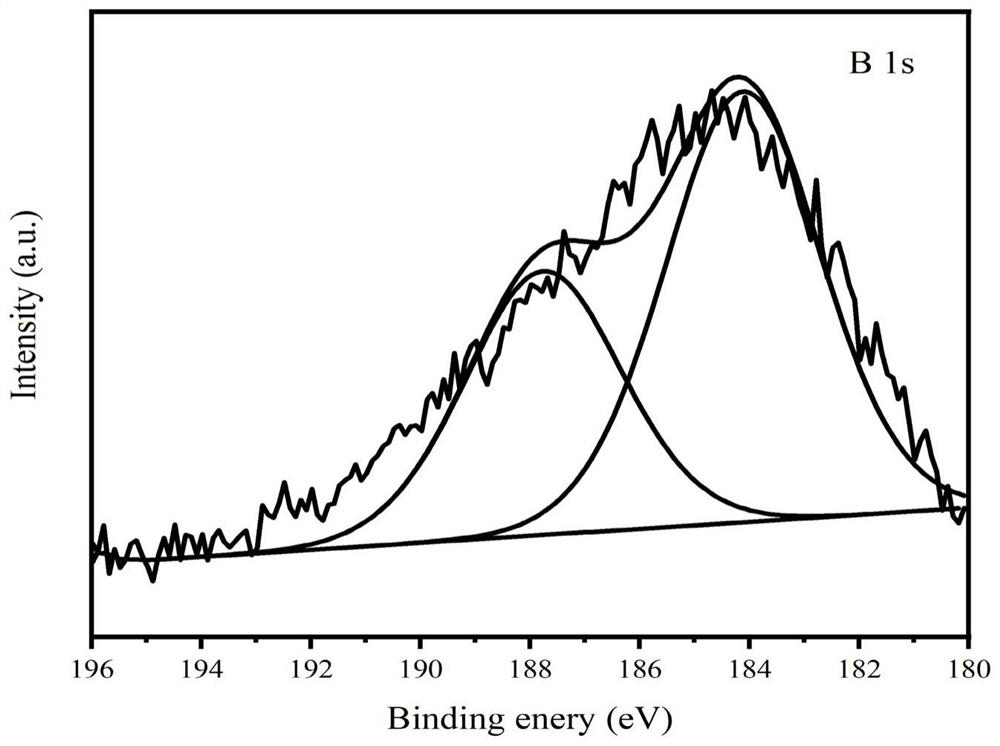

[0020] combine figure 1 As shown, an electrocatalytic material B-VS for ENRR 2 , the material is mainly composed of microspheres with a particle size of about 1 μm.

[0021] Preparation method: Mix 5 mmol of ammonium metavanadate, 15 mmol of thioacetamide, 0.75 mmol of boric acid and 40 mL of ultrapure water, and stir magnetically for 1 hour to obtain a light green turbid liquid. The above liquid was transferred to a microwave reactor, and microwave hydrothermal synthesis was carried out according to the following process: heating from room temperature to 120°C for 10 minutes, and keeping at this temperature for 8 minutes; then heating to 150°C for 10 minutes, and keeping at this temperature for 8 minutes; then Heated to 180°C for 10 minutes, and kept at this temperature for 120 minutes; finally cooled naturally to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com