Tension control method and laser cutting and rolling integrated machine for pole pieces

A laser cutting and all-in-one machine technology, which is applied in the directions of winding strips, sending objects, thin material processing, etc., to achieve the effect of improving production yield and efficiency, improving the quality of pole pieces, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

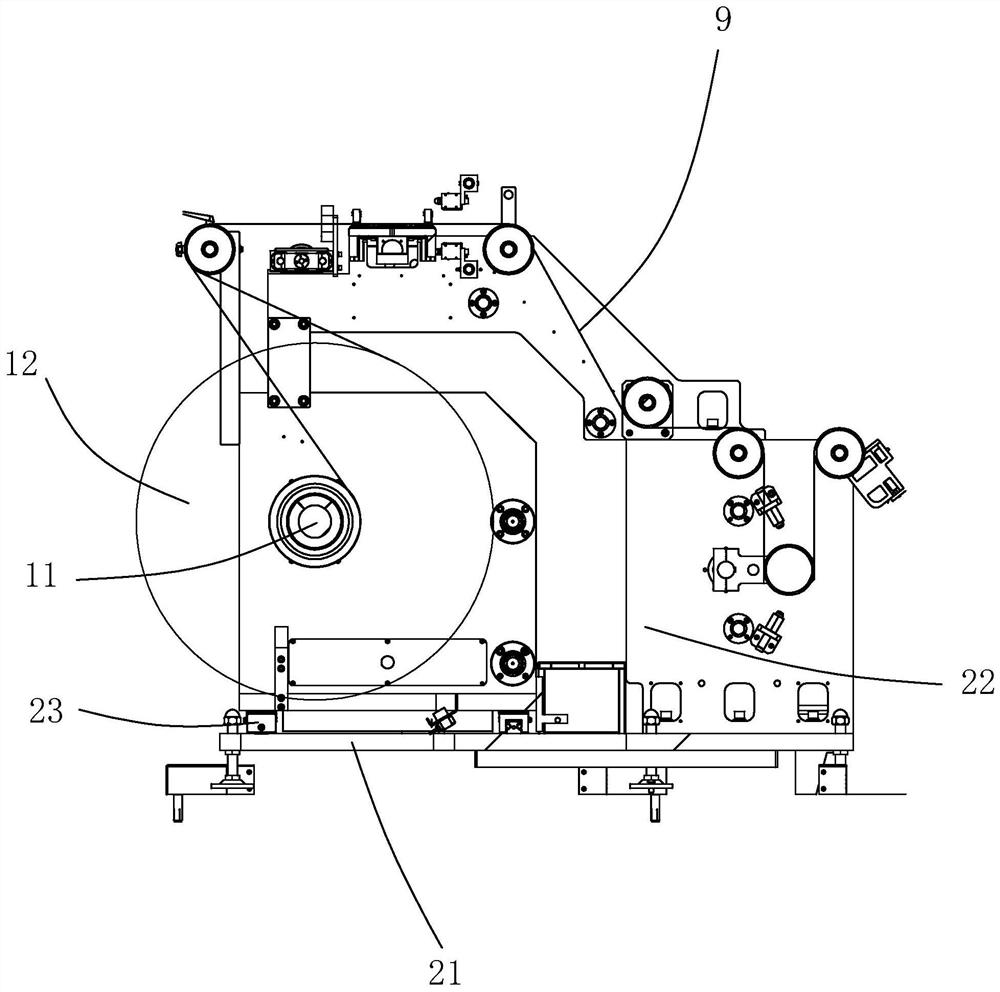

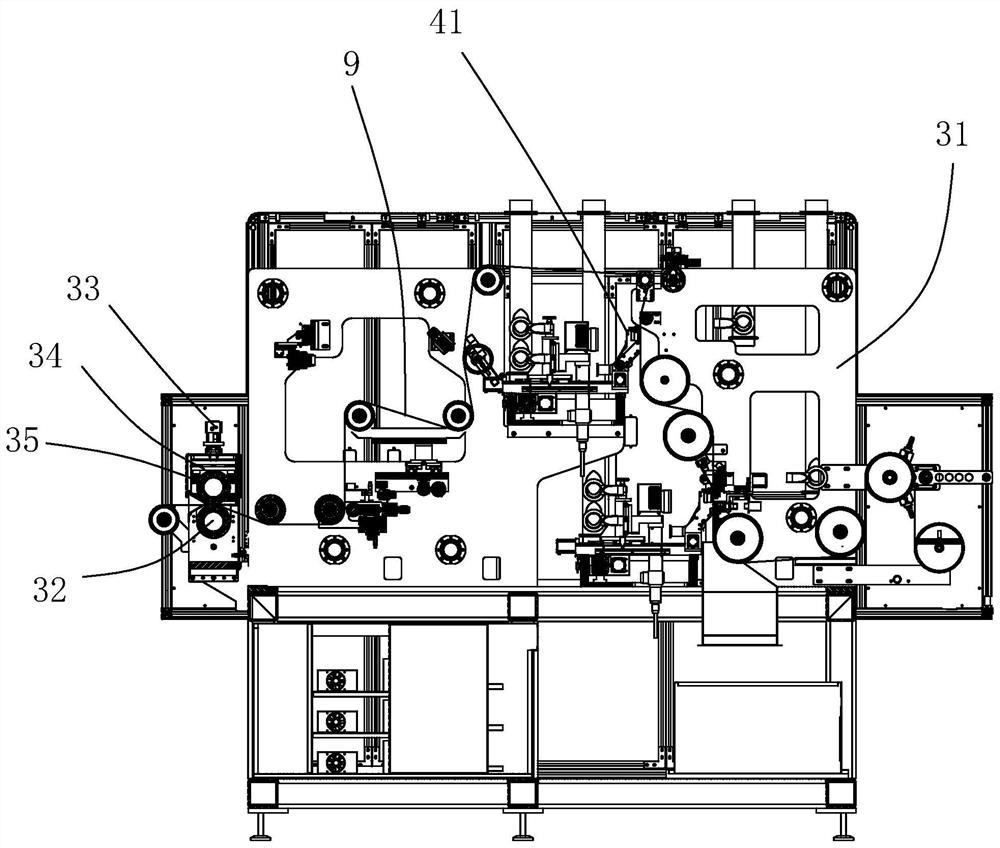

[0045] Embodiment 1 of the present invention, a tension control method and a pole piece laser cutting and rolling machine. The material roll 12 is pulled out, and the pole piece 9 is transported to the laser cutter 41. The laser cutter 41 die-cuts the pole piece 9. After the pole piece 9 is die-cut, it is transported to the pressing roller 62, and the rolling motor 63 The pressure roller 62 is driven to rotate, and the pole piece 9 passes between the two pressure rollers 62. At the same time, the pressure roller 62 rolls the pole piece 9, and the piston rod of the rotating cylinder 54 expands and contracts, and the tension of the pole piece 9 is adjusted. The winding motor works to drive the winding roller 72 to rotate, so that the rolled pole piece 9 is rolled up; the position of the pole piece 9 in the width direction of the pole piece 9 is fed back in real time through the sensor, and the correcting frame 22 is precisely driven to move in a closed loop, thereby adjusting In...

Embodiment 2

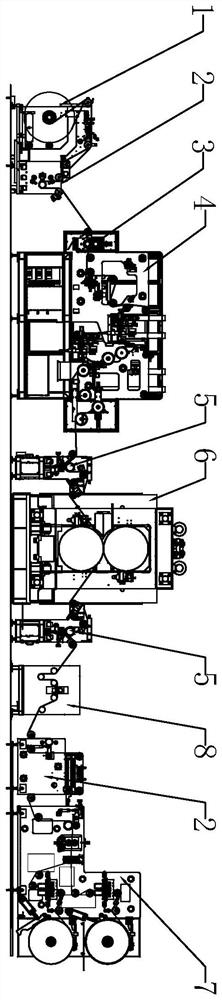

[0046] Embodiment 2: The difference from Embodiment 1 is that the position order of each device of the all-in-one machine is different. Specifically, refer to Figure 7 , including an unwinding device 1, a deviation correcting device 2, a swing roller 53 device 5, a rolling device 6, a traction device 3, a laser die cutting device 4, a detection device 8, a winding device 7 and a control system, and a deviation correcting device 2 There are two devices, one of which is set at the feeding place of the all-in-one machine, and the other one is set at the discharge place of the all-in-one machine, and two pendulum rollers 53 devices 5 are provided. Located on opposite sides of the rolling device 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com