A position control system and method for the axial centering roll of a ring rolling mill

A control system, centering roll technology, applied in metal rolling and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

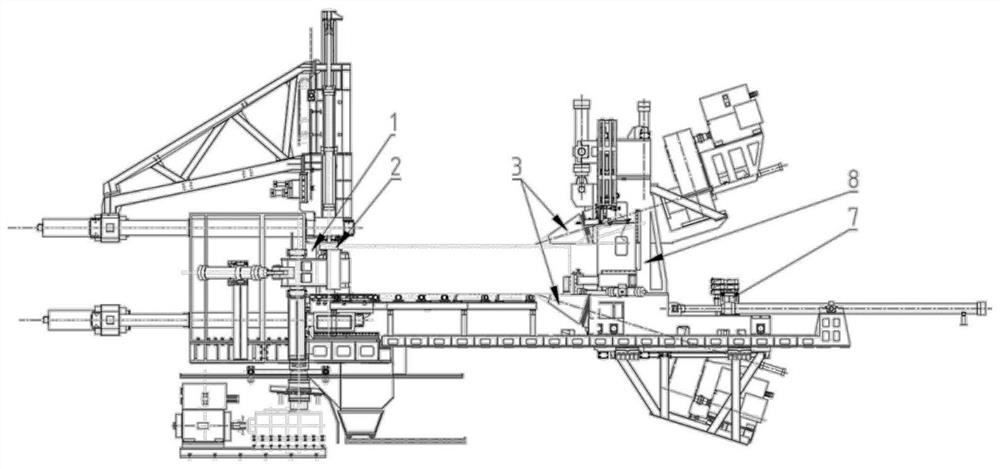

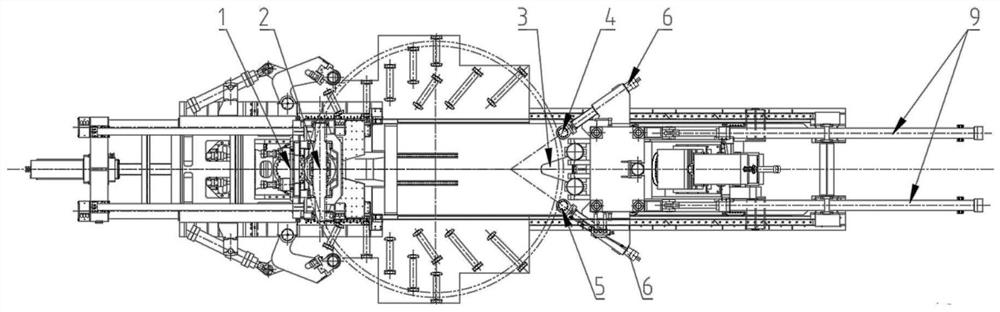

Image

Examples

Embodiment 1

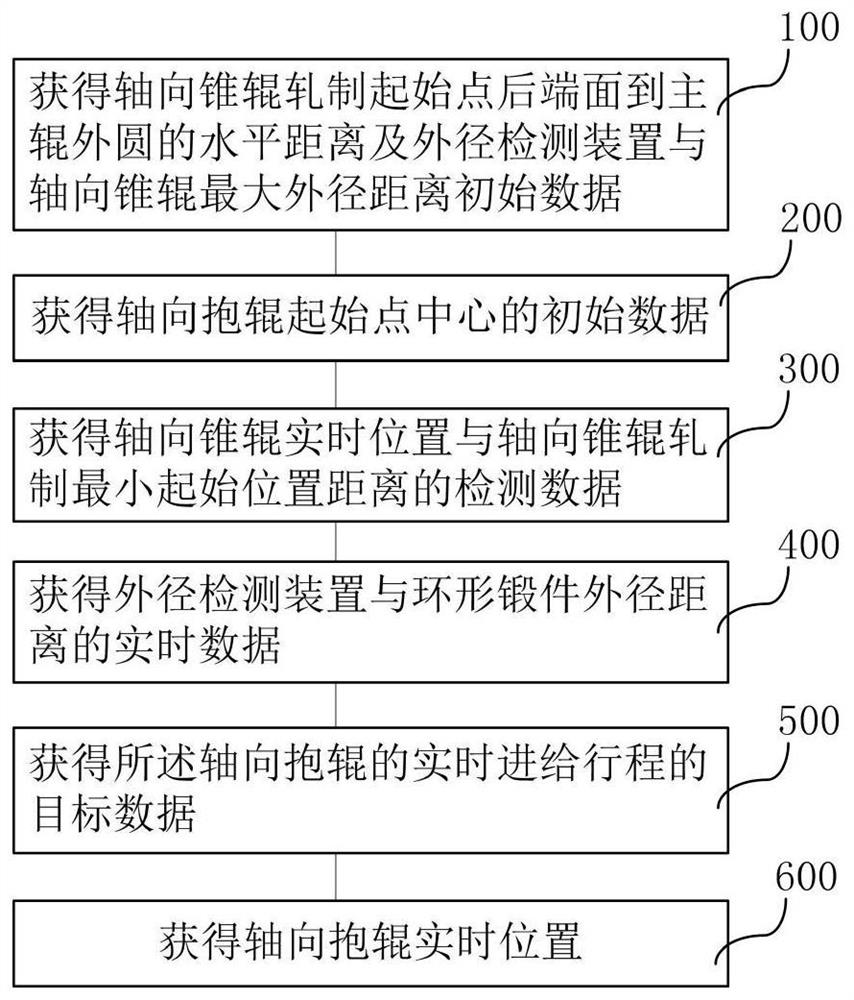

[0048] This embodiment relates to a method for controlling the position of the axial centering roll during the rolling process of a ring rolling mill, see image 3 Shown: the method is used to limit the beating and swinging phenomenon of the annular forging during the rolling process of the ring rolling mill, reduce the offset force caused by asymmetric rolling and reduce the ovality of the annular forging, and the specific steps include:

[0049] Step 100, obtain the initial data B of the horizontal distance from the rear end face of the starting point of the axial tapered roll to the outer circle of the main roll and the distance F between the outer diameter detection device and the maximum outer diameter of the axial tapered roll;

[0050] In step 200, the initial data of the center of the starting point of the axial centering roller is obtained. The initial data of the center of the starting point of the axial centering roller is the horizontal distance V between the cente...

Embodiment 2

[0071] The axial centering roller device involved in this embodiment has a displacement sensor, and the axial centering roller device feeds back its feed data through the displacement sensor.

[0072] In the above embodiment, when the feed of the axial centering roller device is obtained, the feed amount of the axial centering roller device is measured by the displacement sensor in the axial centering roller device, and the displacement sensor finally measures the measured value. Feed data is fed back to the axial centering roll position control system of the ring mill. The axial centering roll position control system of the ring rolling mill finally adjusts the real-time feed stroke of the axial centering roll of the ring rolling mill according to the comparison between the feed amount feedback data and the target data.

Embodiment 3

[0074] The axial centering roller position control involved in this embodiment is to control the centering roller feed position data through the hydraulic servo control system according to the displacement sensor measurement and feedback of the feed amount data.

[0075] In the above embodiment, the hydraulic servo control system controls the displacement feed amount of the axial centering roller by comparing the feedback data of the axial centering roller displacement sensor with the target data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com