Inclined filtering, washing and drying machine

A washing and drying machine, inclined technology, applied in the direction of fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of low heating efficiency, limited filter area, inconvenient operation, etc., to improve heating efficiency , Improve heating efficiency, the effect of large filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

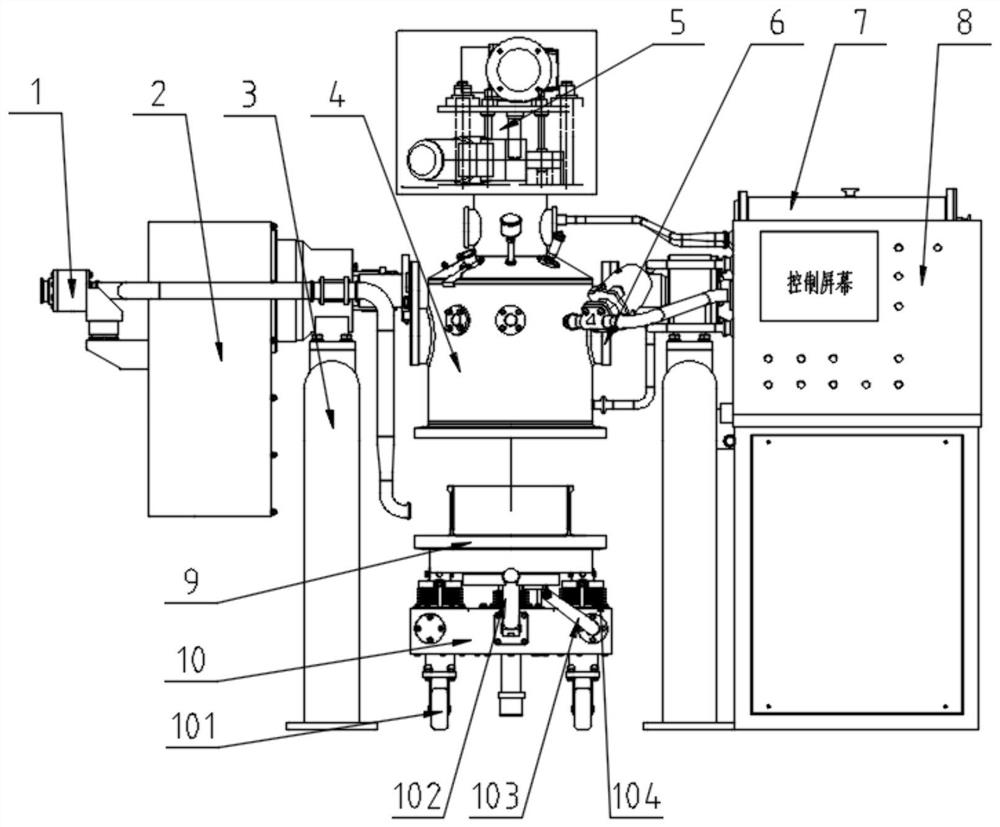

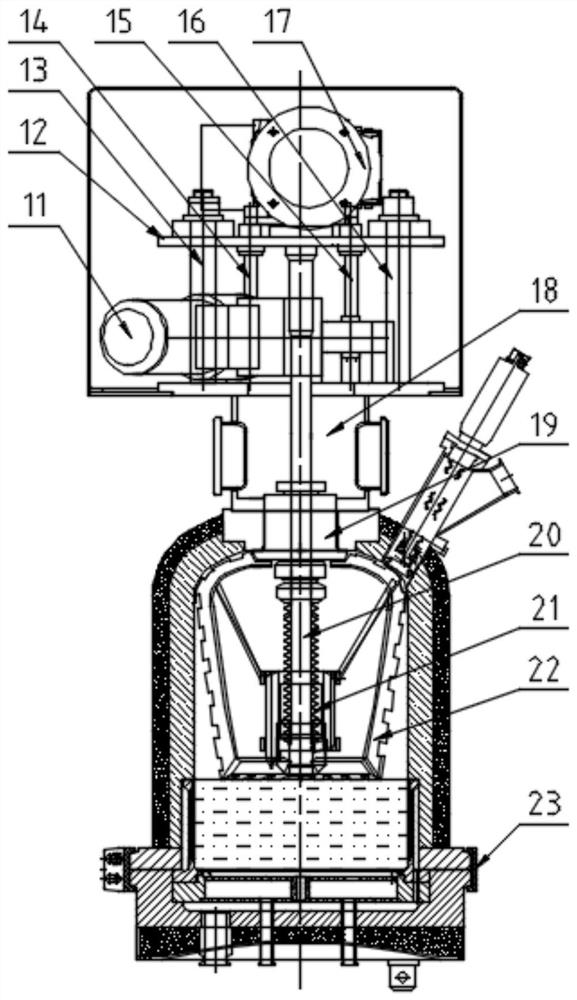

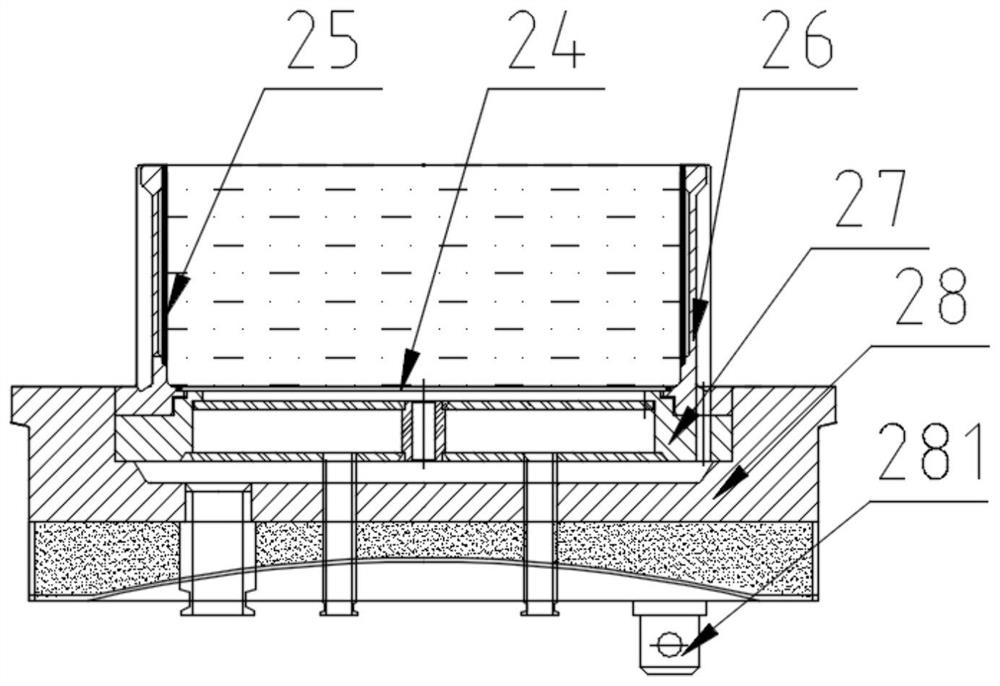

[0031] The invention provides an inclined filter washing and drying machine, such as Figure 1-Figure 8 As shown, it includes mother liquor rotary joint 1, tilting drive (including tilting motor and tilting reducer) 2, outrigger 3, barrel 4, rotating lifting assembly 5, tilting plate 6, auxiliary process barrel 7, control cabinet 8, Filter assembly 9, lifting trolley 10, casters 101, trolley push rod 102, hand rocker 103, corrugated sleeve 104, lifting motor 11, stirring support seat 12, first guide shaft 13, first screw lifter 14, the first Two screw lifter 15, second guide shaft 16, stirring drive (including stirring motor and stirring reducer) 17, stirring lifting support base 18, dry gas mechanical seal 19, stirring shaft 20, bellows 21, stirring paddle 22, Agitator support frame 221, agitator support rod 222, clamp 23, botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com