Coconut meat spraying sterilization processing technology

A spray sterilization and processing technology, applied in food preservation, fixed filter element filter, water/sludge/sewage treatment, etc., can solve the problem that atomized particles are difficult to fall, the amount of coconut meat is adjusted, and a lot of hot water is wasted. and other problems, to achieve the effect of guaranteeing the effect, improving the strength of hot water, and ensuring the safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

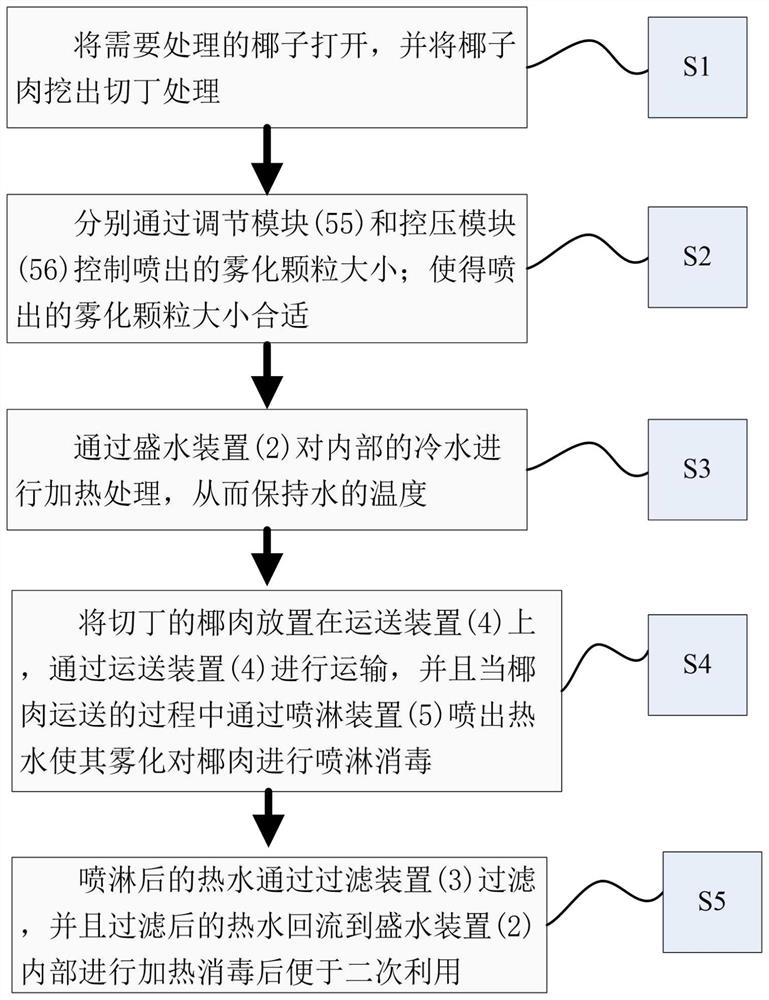

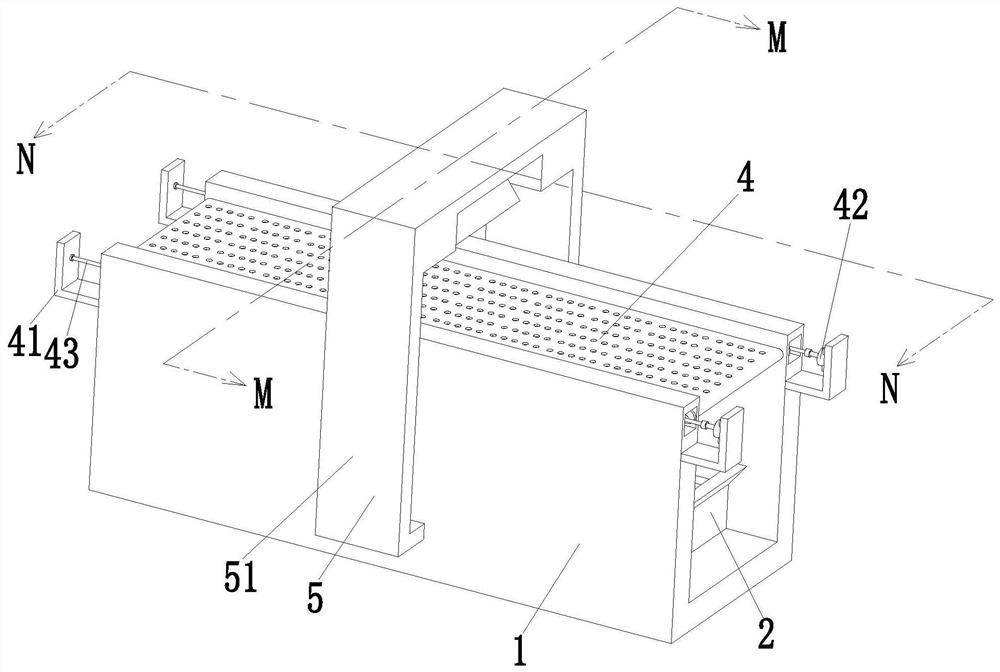

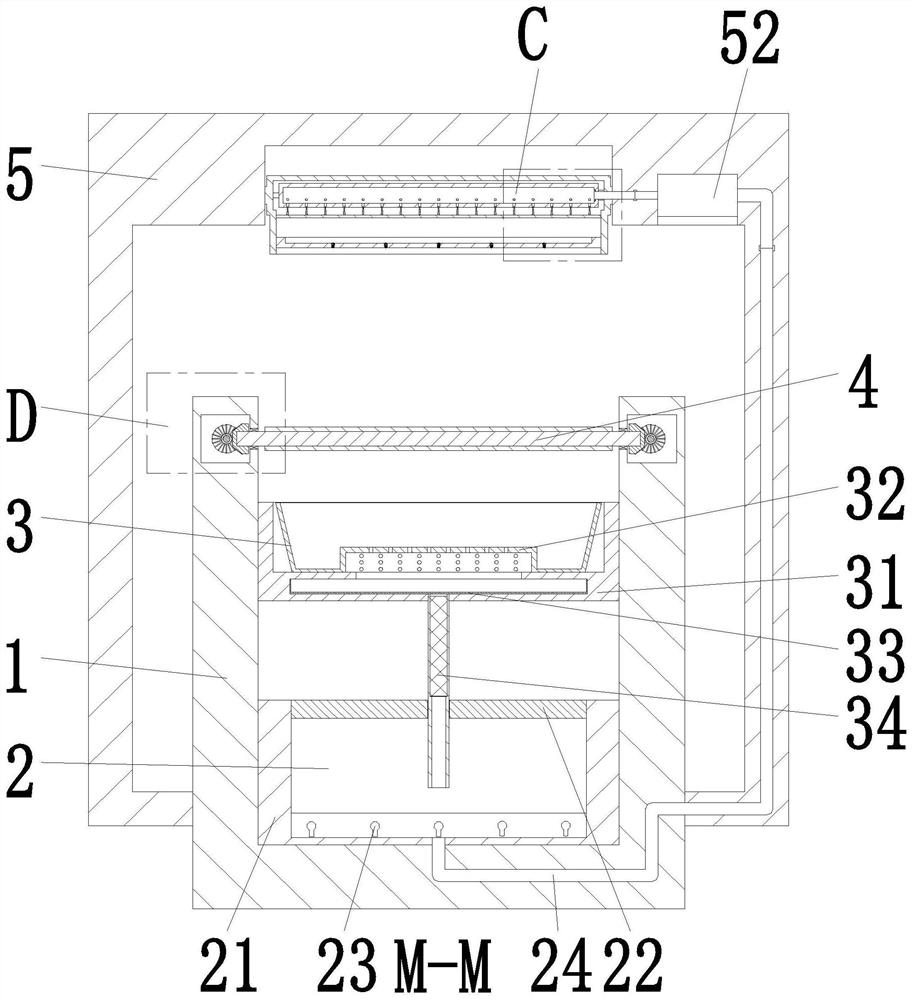

[0039] Such as Figure 1 to Figure 10 Shown, a kind of coconut meat spray sterilization processing technology, the spray sterilization processing step of concrete coconut meat is as follows:

[0040] S1, dicing coconut meat: open the coconut that needs to be processed, and dig out the coconut meat and dice it;

[0041] S2, atomization adjustment: according to the amount of coconut meat to be processed and the amount of coconut meat transported by the delivery device 4; drive the hole-limiting column 555 to move through the electric slider 551, and the hole-limiting column 555 cooperates with the drainage hole at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com