Control method for improving warping of aluminum-based mixed compression structure laminated board and PCB

A control method and technology for PCB boards, which are used in laminated printed circuit boards, multilayer circuit manufacturing, printed circuit manufacturing, etc., can solve problems such as inconsistent expansion and shrinkage changes, affecting product flatness, and prone to board warping and exceeding the standard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

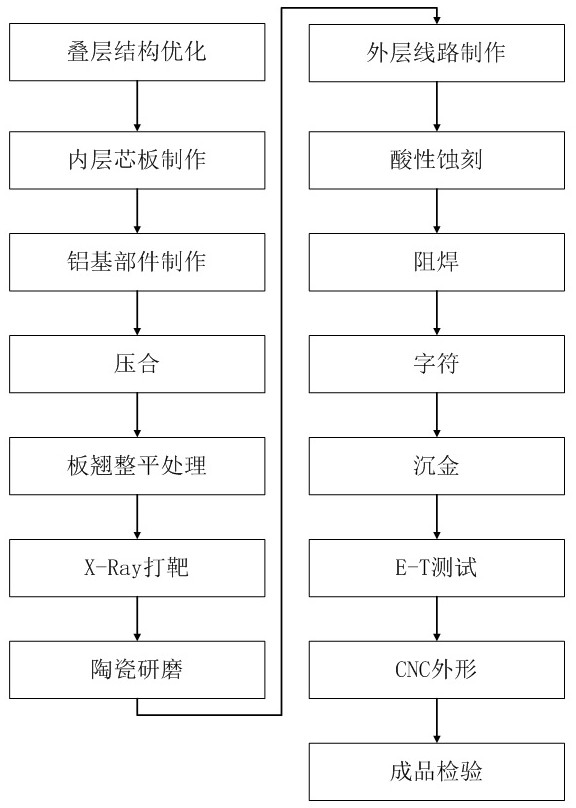

[0098] Embodiment 1: A control method for improving the warping of aluminum-based mixed-compression structure laminates, including

[0099] S1. Laminate structure optimization, select the aluminum base 100 and the inner core plate 200 with preset thickness and hardness, so that the thickness ratio of the aluminum base 100 and the core plate dielectric layer 210 in the inner core plate 200 is 10:1;

[0100] S2. Fabrication of inner core board;

[0101] S3. Production of aluminum-based components. After the aluminum-based 100 is cut, the aluminum-based 100 is pre-hot-pressed once by a conventional hot-pressing method; the parameters of the conventional hot-pressing method are: the furnace temperature is 140°C, and the heating rate is 1.8°C-2.2 ℃ / min, pressure 30 kg -40kg / cm2, 200 ℃ heat preservation and pressing ≥ 60min.

[0102] S4, pressing, pressing the inner core board 200 and the aluminum base 100 together with a vacuum laminator;

[0103] S5, plate warping leveling treat...

Embodiment 2

[0116] Embodiment 2: A control method for improving the warping of aluminum-based mixed-compression structure laminates, including

[0117] S1. Laminate structure optimization, select the aluminum base 100 and the inner layer core board 200 with preset thickness and hardness, so that the thickness ratio of the aluminum base 100 and the core board dielectric layer 210 in the inner layer core board 200 is 15:1;

[0118] S2. Fabrication of inner core board;

[0119] S3. Production of aluminum-based components. After the aluminum-based 100 is cut, the aluminum-based 100 is pre-hot-pressed once by the rapid hot-pressing method; the parameters of the rapid hot-pressing method are: the furnace temperature is 160°C-200°C, and the heating rate is 5 ℃-10℃ / min, pressure 30kg-40kg / cm2, heat preservation and pressing at 200℃ for 20min.

[0120] S4, pressing, pressing the inner core board 200 and the aluminum base 100 together with a vacuum laminator;

[0121] S5, plate warping leveling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com