Telescopic irradiation sample hole plug

A retractable and irradiated technology, applied in the field of nuclear power reactors, can solve the problems of inability to realize stable self-locking and plugging, and achieve the effect of simple structure, convenient operation and stable self-locking state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

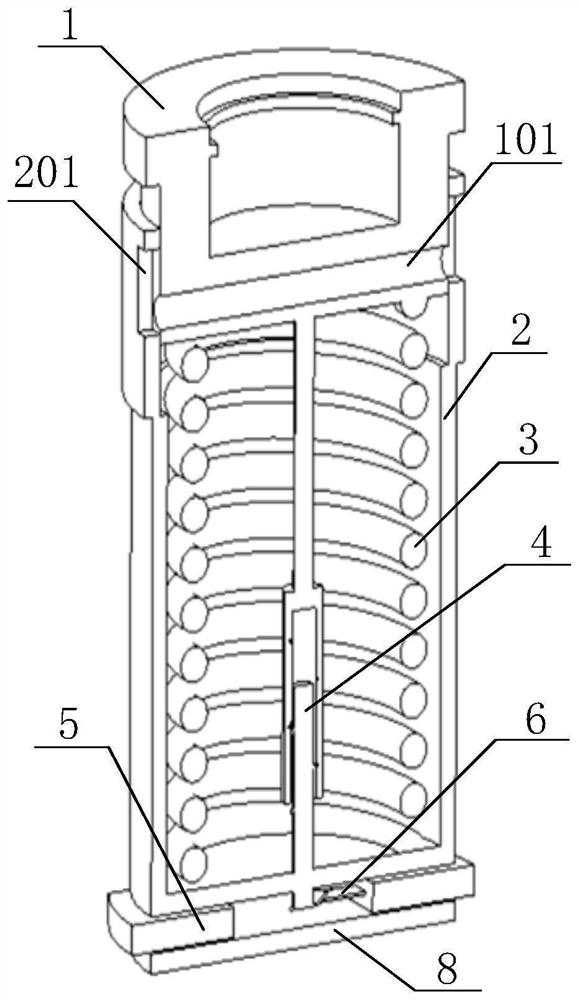

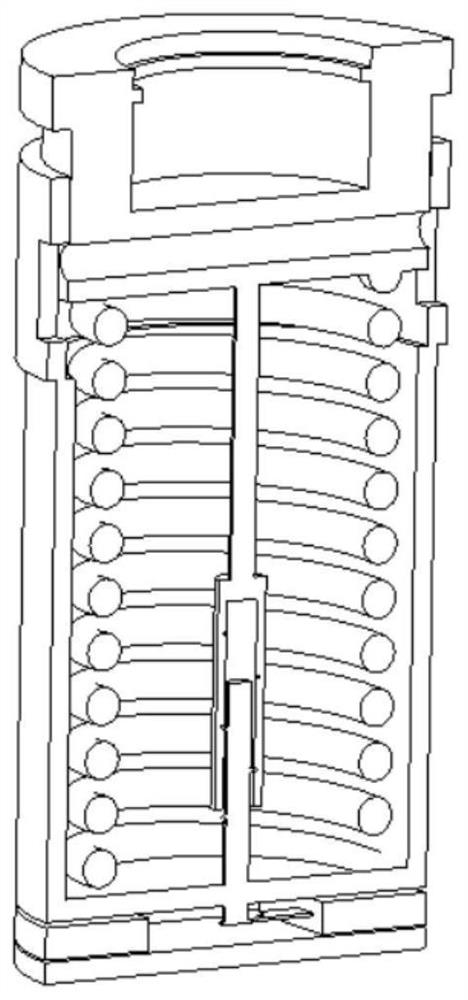

[0041] Such as Figure 1-Figure 4 As shown, a telescopic irradiation sample hole plug includes an upper end cover 1, a main body of the irradiation plug 2, an inner spring 3, a telescopic structure 4, a self-locking block 5, a "Z" type connector 6 and a lower bottom plate 8;

[0042] The irradiation plug main body 2 is a hollow structure with an open top, the upper end cover 1 is slidably arranged on the upper end of the irradiation plug main body 2, the lower bottom plate 8 is arranged below the irradiation plug main body 2, and the lower bottom plate 8 A cavity for accommodating the self-locking block 5 is formed between the bottom of the main body 2 and the irradiation plug body;

[0043] The upper end and the lower end of the inner cavity spring 3 are respectively connected with the bottom of the upper end cover 1 and the inner cavity bottom of the irradiation plug main body 2;

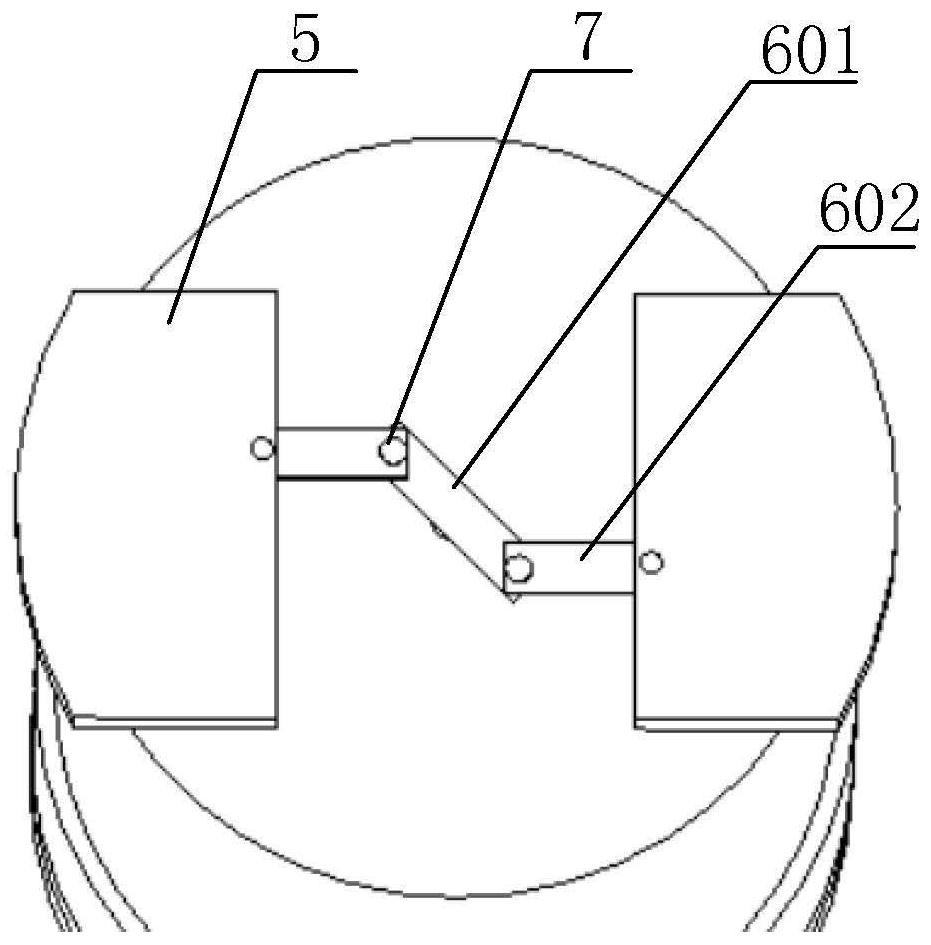

[0044] Both the self-locking block 5 and the "Z"-shaped connecting piece 6 are arranged in th...

Embodiment 2

[0054] Such as Figure 1-Figure 4 As shown, this embodiment is based on Embodiment 1. The upper side wall of the irradiation plug main body 2 is symmetrically provided with two limiting through grooves 201, and the limiting through grooves 201 are used to communicate with the inner surface of the irradiation plug main body 2. Cavity and external space, the side wall of the upper end cover 1 is provided with a limit block that cooperates with the limit channel 201, and the limit block protrudes from the limit channel 201 in the horizontal direction; the upper end cover 1 is provided with a through hole 101, the limit block is provided with a through groove, and the through hole 101 is communicated with the through groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com