Composite insulator defect detection method

A composite insulator and defect detection technology, applied in the field of defect detection, can solve problems such as insignificant temperature rise and achieve the effect of simplifying calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

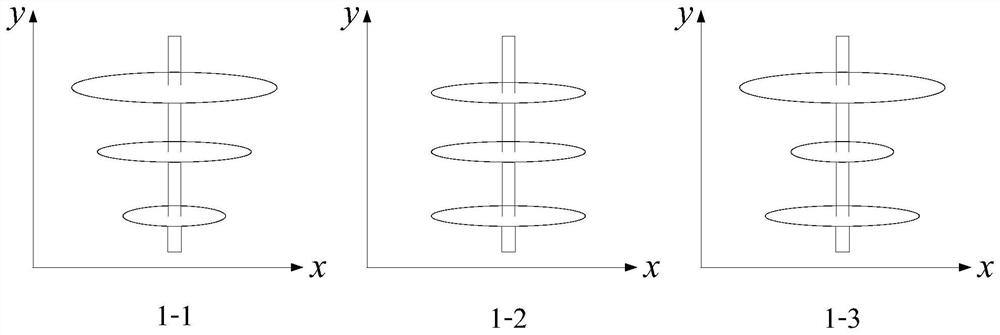

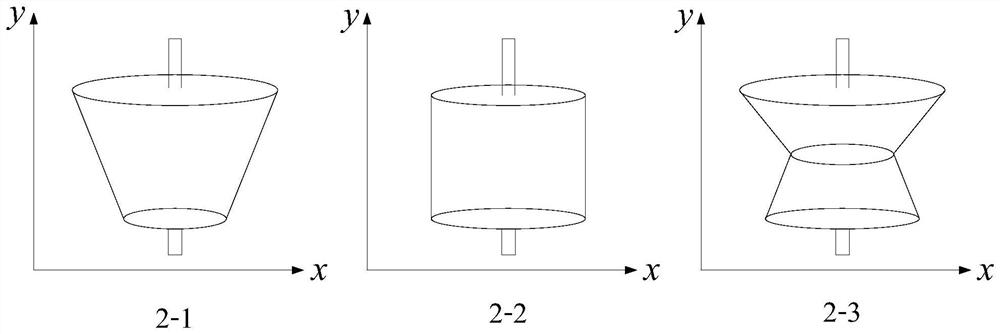

[0038] In this embodiment, a composite insulator defect detection method includes the following steps:

[0039] T1: Use the infrared instrument to obtain the infrared image of the composite insulator string;

[0040] T2: Read the temperature distribution of each composite insulator in the composite insulator string through infrared images, but due to the complex temperature distribution of each composite insulator, the temperature distribution function is difficult to fit, and the on-site processing is very difficult. In order to make this patent application more practical properties, select the maximum temperature of each composite insulator As a function of its temperature distribution, this data can more effectively find out the defective composite insulator with the largest temperature rise; where, i∈(1,n), n is the number of composite insulators in the composite insulator string;

[0041] T3: Maximum temperature for each composite insulator Find the corresponding surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com