Rapid evaluation method for electrochemical corrosion resistance of metal bipolar plate coatings for fuel cells

A metal bipolar plate, fuel cell technology, applied in the direction of weather resistance/light resistance/corrosion resistance, scientific instruments, analytical materials, etc. Cost, broad application prospects, rapid and accurate evaluation of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In this embodiment,

[0056] A rapid evaluation method for electrochemical corrosion resistance of metal bipolar plate coatings of fuel cells Corrosion polarization tests for 3h, 6h, 9h, 12h and 24h were carried out under potential conditions, and five parallel samples were repeated for each condition, including the following steps:

[0057] Step 1, measure the contact resistance:

[0058] Using an electronic micro-ohmmeter, test the contact resistance of the coating after different corrosion times under the condition of constant potential polarization, and obtain a series of contact resistance data;

[0059] Step 2, regression analysis:

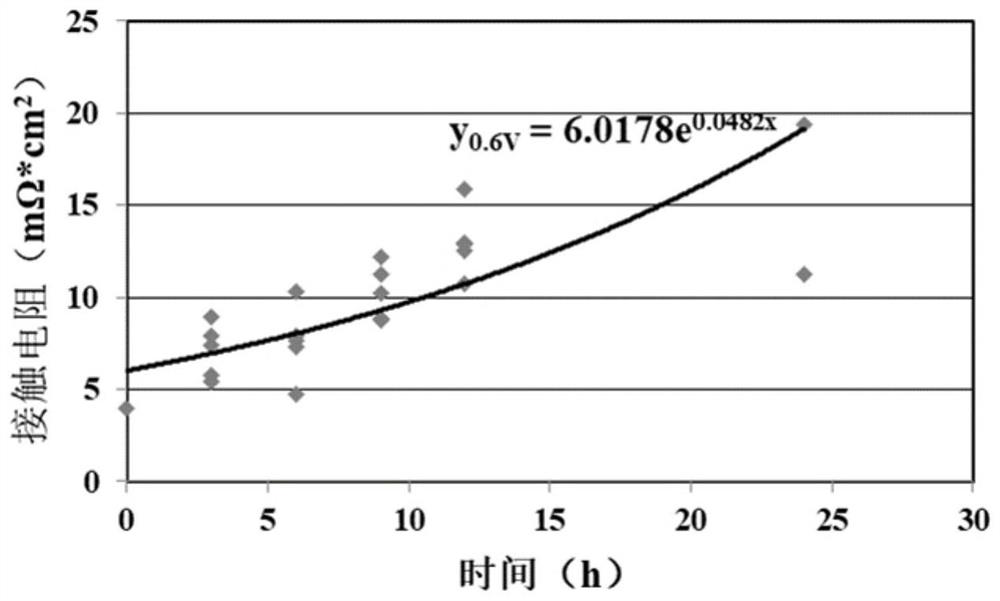

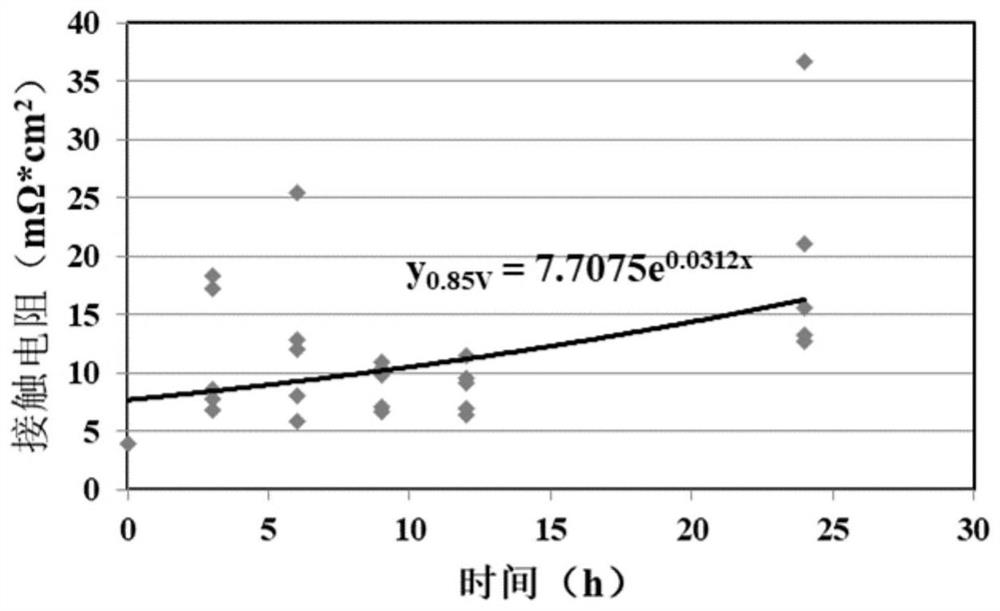

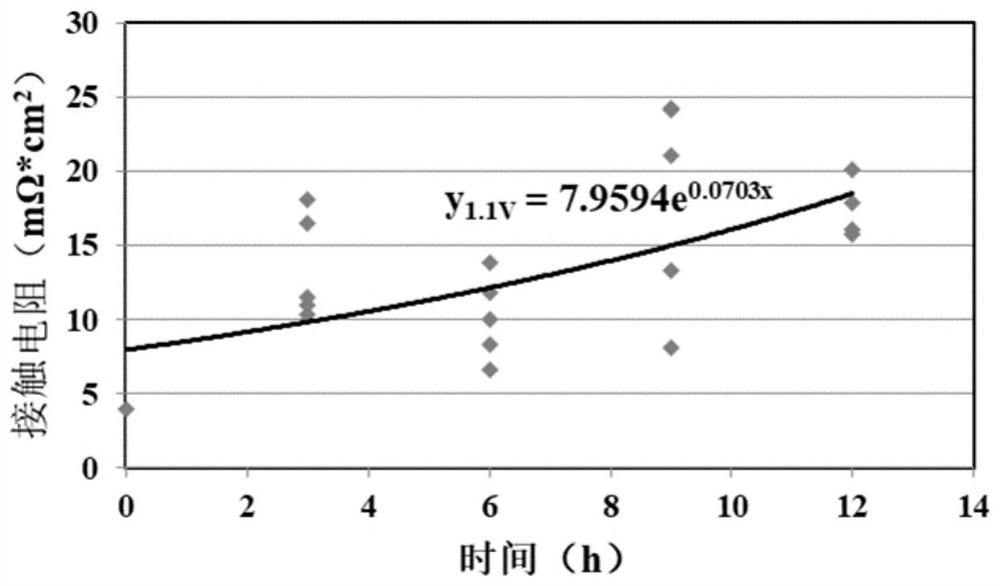

[0060] Do an exponential regression of the contact resistance obtained in step 1 to the corrosion time, or do a linear regression of the logarithm of the contact resistance to the time to obtain the corresponding growth coefficient a under the corrosion potential, that is, the expression a = F(V) , the result is figure 1 ~ As show...

Embodiment 2

[0070] This embodiment is basically the same as the first embodiment, and the special features are:

[0071] In this embodiment, the service conditions of the metal bipolar plate coating are decomposed into several intervals, and the contact resistance growth coefficients of different intervals are different, and the service time of the corresponding interval is used to accurately evaluate the tolerance of the metal bipolar plate coating. . Specifically, based on the principle that the contact resistance of the bipolar plate coating increases exponentially with the corrosion time under constant potential conditions, the service conditions of the fuel cell metal bipolar plate coating are decomposed into several intervals, so that each constant potential The contact resistance growth coefficient under the condition is combined with the corresponding unit service time ratio, so as to comprehensively judge the tolerance of the coating under this working condition. As shown in for...

Embodiment 3

[0084] This embodiment is basically the same as the previous embodiment, and the special features are:

[0085] In this embodiment, the metal bipolar plates of two different coating products G and H are alternately installed into a fuel cell stack, each with five cells, and the stack is disassembled and taken out after every 1000h of operation. The bipolar plate was used to measure the contact resistance, and the results are shown in Table 3:

[0086] Table 3. Contact resistance data for coatings H and J running in short stack (unit: mΩcm 2 )

[0087]

[0088] It can be seen that during the operation of the stack, the contact resistance of each bipolar plate coating is less than 10mΩcm 2 , and the increase is less than 3mΩcm 2 , the change is not obvious, and theoretically obtaining the tolerance results of these two coatings requires follow-up operation verification. In short, although the method of on-line measurement of the stack can directly prove the life of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com